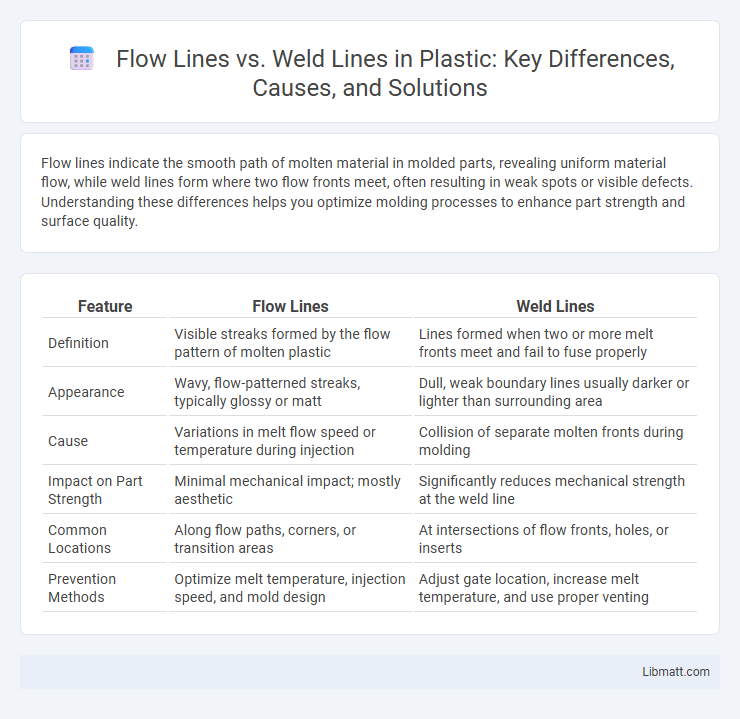

Flow lines indicate the smooth path of molten material in molded parts, revealing uniform material flow, while weld lines form where two flow fronts meet, often resulting in weak spots or visible defects. Understanding these differences helps you optimize molding processes to enhance part strength and surface quality.

Table of Comparison

| Feature | Flow Lines | Weld Lines |

|---|---|---|

| Definition | Visible streaks formed by the flow pattern of molten plastic | Lines formed when two or more melt fronts meet and fail to fuse properly |

| Appearance | Wavy, flow-patterned streaks, typically glossy or matt | Dull, weak boundary lines usually darker or lighter than surrounding area |

| Cause | Variations in melt flow speed or temperature during injection | Collision of separate molten fronts during molding |

| Impact on Part Strength | Minimal mechanical impact; mostly aesthetic | Significantly reduces mechanical strength at the weld line |

| Common Locations | Along flow paths, corners, or transition areas | At intersections of flow fronts, holes, or inserts |

| Prevention Methods | Optimize melt temperature, injection speed, and mold design | Adjust gate location, increase melt temperature, and use proper venting |

Introduction to Flow Lines and Weld Lines

Flow lines are visible patterns that form on a molded part's surface, caused by the varying speed and temperature of the molten material as it flows into the mold cavity. Weld lines, also known as knit lines, occur where two or more flow fronts meet and fail to fuse properly, often leading to weak points in the molded part. Understanding the difference between flow lines and weld lines helps you optimize molding conditions and improve the quality and strength of your plastic components.

Understanding Flow Lines in Injection Molding

Flow lines in injection molding appear as visible streaks or patterns on the molded part's surface caused by variations in polymer flow speed and temperature during filling. These lines often indicate areas where the molten plastic cools unevenly, potentially affecting the mechanical properties and aesthetic quality of the final product. Understanding flow lines helps optimize mold design and processing parameters to ensure uniform material flow and enhance part integrity.

What are Weld Lines and How Do They Form?

Weld lines are defects in injection molded parts where two or more flow fronts meet but fail to bond properly, resulting in weak spots or visible lines on the surface. They form when molten plastic flows around an obstruction or splits during the molding process, cooling before fully merging back together. Factors influencing weld line formation include material viscosity, mold temperature, injection speed, and part geometry.

Key Differences Between Flow Lines and Weld Lines

Flow lines are surface imperfections that appear as subtle, irregular lines caused by the cooling and flow pattern of molten plastic during injection molding, whereas weld lines form when two or more flow fronts meet but fail to fuse properly, creating a visible seam or weak spot. Flow lines typically affect the aesthetic quality without significantly compromising part strength, while weld lines can lead to structural weaknesses and potential failure points in your molded product. Understanding these differences is crucial for optimizing mold design and processing parameters to enhance both the appearance and durability of your parts.

Causes of Flow Lines in Molded Parts

Flow lines in molded parts are caused by variations in the cooling rate and flow velocity of the molten plastic as it fills the mold cavity. These lines often occur when material flows around obstacles or changes direction abruptly, leading to differences in temperature and pressure. Insufficient mold temperature control, low injection speed, or improper gate placement can exacerbate the formation of flow lines, impacting the surface aesthetics and structural integrity of the part.

Factors Contributing to Weld Lines

Weld lines form when two or more flow fronts of molten material meet but do not fuse properly, often caused by abnormal cooling rates, insufficient melt temperature, or low injection pressure. Material viscosity, gate design, and mold temperature influence weld line formation by affecting flow front speed and pressure. Understanding shear rate and molecular orientation helps optimize process conditions to minimize weld lines and improve part strength in injection molding.

Impact of Flow Lines on Product Quality

Flow lines are surface defects that appear as streaks or patterns caused by variations in the cooling rate of molten material during the molding process, often compromising the aesthetic quality and potentially indicating weak points in the product. Weld lines form where two or more flow fronts meet, leading to possible structural weaknesses and visible seam lines that detract from the product's integrity and appearance. Your product's durability and visual appeal can significantly decline if these flow and weld lines are not properly managed during manufacturing.

Effects of Weld Lines on Mechanical Strength

Weld lines occur when two flow fronts meet during the injection molding process, creating a weak interface that can significantly reduce mechanical strength and lead to part failure under stress. These lines act as stress concentrators, disrupting the continuity of the polymer matrix and lowering tensile and impact resistance. To improve your part's durability, optimizing mold design and processing parameters can help minimize weld line formation and enhance overall structural integrity.

Methods to Prevent Flow Lines and Weld Lines

To prevent flow lines and weld lines during injection molding, optimize processing parameters such as increasing mold temperature and injection speed to ensure uniform material flow and proper cavity filling. Utilize advanced mold designs with balanced runners and adequate venting to reduce flow interruptions and minimize weld line formation. Incorporate material selection strategies like using compatible resin blends and adding flow enhancers to improve melt flow consistency and weld line strength.

Best Practices for Minimizing Surface Defects in Injection Molding

Minimizing surface defects such as flow lines and weld lines in injection molding requires careful control of mold temperature, injection speed, and pressure to ensure uniform material flow and proper fusion of molten plastic. Optimizing gate locations and using balanced flow paths help reduce the formation of weld lines by promoting consistent material flow fronts. Your ability to fine-tune process parameters and mold design directly influences the aesthetic quality and structural integrity of molded parts.

Flow Lines vs Weld Lines Infographic

libmatt.com

libmatt.com