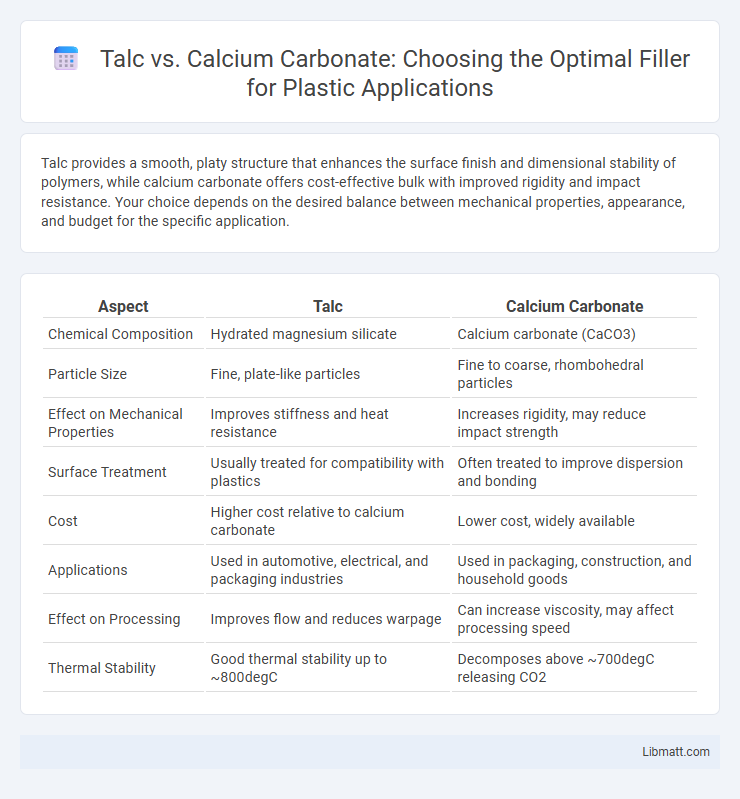

Talc provides a smooth, platy structure that enhances the surface finish and dimensional stability of polymers, while calcium carbonate offers cost-effective bulk with improved rigidity and impact resistance. Your choice depends on the desired balance between mechanical properties, appearance, and budget for the specific application.

Table of Comparison

| Aspect | Talc | Calcium Carbonate |

|---|---|---|

| Chemical Composition | Hydrated magnesium silicate | Calcium carbonate (CaCO3) |

| Particle Size | Fine, plate-like particles | Fine to coarse, rhombohedral particles |

| Effect on Mechanical Properties | Improves stiffness and heat resistance | Increases rigidity, may reduce impact strength |

| Surface Treatment | Usually treated for compatibility with plastics | Often treated to improve dispersion and bonding |

| Cost | Higher cost relative to calcium carbonate | Lower cost, widely available |

| Applications | Used in automotive, electrical, and packaging industries | Used in packaging, construction, and household goods |

| Effect on Processing | Improves flow and reduces warpage | Can increase viscosity, may affect processing speed |

| Thermal Stability | Good thermal stability up to ~800degC | Decomposes above ~700degC releasing CO2 |

Introduction to Fillers in Industrial Applications

Fillers such as talc and calcium carbonate play critical roles in industrial applications by enhancing material properties and reducing production costs. Talc, a soft mineral with excellent lubricity and moisture resistance, is ideal for plastics and paints, whereas calcium carbonate offers superior brightness, opacity, and low abrasiveness, commonly used in paper and rubber industries. Your choice of filler influences product durability, texture, and overall performance in manufacturing processes.

Overview of Talc and Calcium Carbonate

Talc is a hydrated magnesium silicate mineral known for its lamellar structure, softness, and excellent lubricating properties, making it a preferred filler in plastics, paints, and paper. Calcium carbonate, primarily sourced from limestone, is a widely used inorganic filler prized for its whiteness, high brightness, and ability to improve mechanical properties and reduce production costs in various industries. Both fillers impact product performance differently due to their distinct chemical compositions, particle sizes, and surface treatments.

Physical and Chemical Properties Comparison

Talc, characterized by its lamellar structure and hydrophobic nature, provides excellent lubricity and dimensional stability as a filler, while calcium carbonate, a crystalline mineral with a high brightness and alkaline pH, enhances opacity and neutralizes acidity in formulations. Talc's magnesium silicate composition gives it high thermal stability and chemical inertness, whereas calcium carbonate's calcium carbonate composition results in higher density and greater hardness. The choice between talc and calcium carbonate fillers depends on desired product attributes like surface finish, reinforcement capability, and chemical reactivity.

Performance Impact on Product Quality

Talc offers superior slip and improved surface finish, enhancing the aesthetic quality and smoothness of products, while calcium carbonate provides cost-effective opacity and brightness, boosting bulk and rigidity. Your choice between talc and calcium carbonate directly impacts product durability, with talc increasing heat resistance and calcium carbonate improving stiffness but potentially reducing impact strength. Optimizing filler selection helps balance performance attributes such as texture, strength, and cost to meet specific quality requirements.

Cost Considerations and Economic Efficiency

Talc generally offers superior performance as a filler but comes at a higher cost compared to calcium carbonate, impacting overall production expenses. Calcium carbonate is more economical, providing cost-efficiency for large-scale manufacturing while maintaining acceptable quality in many applications. Choosing the right filler depends on your balance between budget constraints and desired product properties for optimal economic efficiency.

Processing and Compatibility with Polymers

Talc exhibits excellent processing characteristics due to its lamellar structure, enhancing polymer stiffness and dimensional stability without significantly affecting melt flow properties. Calcium carbonate, with its fine particulate nature, offers superior dispersion and compatibility in various polymers, improving impact resistance and surface finish. Both fillers influence polymer crystallinity and mechanical performance differently, requiring careful selection based on specific processing techniques and target polymer matrices.

Environmental and Health Impacts

Talc, a mineral composed mainly of magnesium, silicon, and oxygen, has raised health concerns due to potential asbestos contamination, which is linked to respiratory issues and cancer, prompting strict regulations in many countries. Calcium carbonate, derived primarily from limestone, is considered more environmentally friendly and safer for human health, as it is non-toxic and abundant, requiring less energy-intensive processing. Choosing calcium carbonate over talc as a filler reduces the risk of toxic exposure and lowers environmental impact through more sustainable mining and disposal processes.

Applications in Various Industries

Talc and calcium carbonate are widely used fillers in industries such as plastics, paints, and paper manufacturing due to their unique properties. Talc's lamellar structure offers excellent lubrication and improves mechanical properties, making it ideal for automotive parts and cosmetics. Calcium carbonate provides superior brightness and opacity, enhancing products like coatings, adhesives, and food packaging, ensuring Your products maintain high quality and performance.

Recent Innovations and Market Trends

Recent innovations in filler materials highlight the development of surface-modified talc and nano-sized calcium carbonate, enhancing composite performance in automotive and plastics industries. Market trends indicate a rising preference for bio-based calcium carbonate due to its sustainability and cost-effectiveness compared to talc, which faces regulatory scrutiny over health concerns. Advanced functionalization techniques improve talc's compatibility in polymer matrices, driving niche applications despite calcium carbonate's dominance in volume and price-driven markets.

Choosing the Right Filler: Key Decision Factors

Choosing the right filler between talc and calcium carbonate depends on factors such as desired mechanical properties, surface finish, and processing conditions. Talc offers superior reinforcement, improves stiffness, and enhances thermal stability, making it ideal for applications requiring high dimensional stability. Calcium carbonate provides cost-effective bulk, improved opacity, and better dispersion, suited for products prioritizing brightness and affordability.

Using Talc vs Calcium Carbonate as Fillers Infographic

libmatt.com

libmatt.com