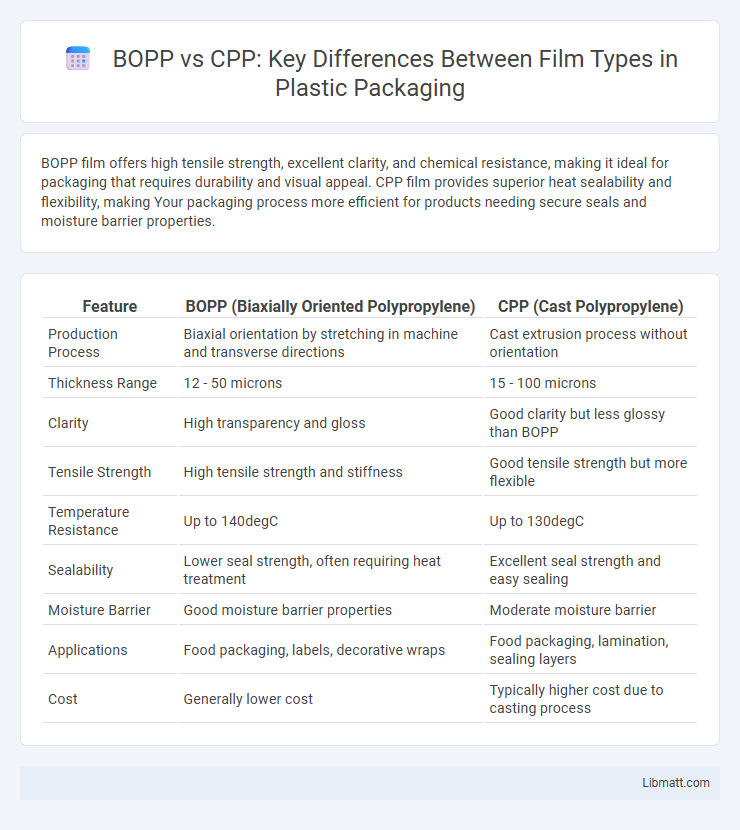

BOPP film offers high tensile strength, excellent clarity, and chemical resistance, making it ideal for packaging that requires durability and visual appeal. CPP film provides superior heat sealability and flexibility, making Your packaging process more efficient for products needing secure seals and moisture barrier properties.

Table of Comparison

| Feature | BOPP (Biaxially Oriented Polypropylene) | CPP (Cast Polypropylene) |

|---|---|---|

| Production Process | Biaxial orientation by stretching in machine and transverse directions | Cast extrusion process without orientation |

| Thickness Range | 12 - 50 microns | 15 - 100 microns |

| Clarity | High transparency and gloss | Good clarity but less glossy than BOPP |

| Tensile Strength | High tensile strength and stiffness | Good tensile strength but more flexible |

| Temperature Resistance | Up to 140degC | Up to 130degC |

| Sealability | Lower seal strength, often requiring heat treatment | Excellent seal strength and easy sealing |

| Moisture Barrier | Good moisture barrier properties | Moderate moisture barrier |

| Applications | Food packaging, labels, decorative wraps | Food packaging, lamination, sealing layers |

| Cost | Generally lower cost | Typically higher cost due to casting process |

Introduction to BOPP and CPP Films

BOPP (Biaxially Oriented Polypropylene) and CPP (Cast Polypropylene) films are widely used in flexible packaging due to their distinct physical and chemical properties. BOPP films are stretched in two directions, enhancing strength, clarity, and barrier properties, making them ideal for food packaging and labeling. CPP films offer superior sealability, flexibility, and heat resistance, often used as sealant layers or for applications requiring high mechanical toughness.

Key Differences Between BOPP and CPP

BOPP (Biaxially Oriented Polypropylene) is a highly transparent, stiff film with excellent moisture resistance and superior printability, commonly used in food packaging and labeling. CPP (Cast Polypropylene) offers greater flexibility, impact resistance, and higher seal strength, making it ideal for flexible packaging and lamination applications. The key differences lie in their mechanical properties, with BOPP providing better stiffness and clarity, while CPP excels in heat sealability and elongation.

Physical Properties Comparison

BOPP (Biaxially Oriented Polypropylene) film exhibits high tensile strength, excellent clarity, and effective moisture barrier properties, making it ideal for packaging applications requiring durability and visual appeal. CPP (Cast Polypropylene) film offers superior impact resistance, greater flexibility, and higher heat seal strength compared to BOPP, which is beneficial for applications needing enhanced seal integrity and conformability. Both films demonstrate good chemical resistance and transparency, but BOPP excels in stiffness and barrier performance while CPP provides better elongation and seal toughness.

Barrier Performance: Moisture and Gas

BOPP (Biaxially Oriented Polypropylene) films exhibit excellent moisture barrier properties, making them ideal for protecting products from humidity and maintaining freshness. CPP (Cast Polypropylene) films offer superior gas barrier performance, effectively preventing oxygen and other gases from permeating and extending shelf life. Your packaging choice depends on whether moisture or gas resistance is the priority for product protection.

Applications in Packaging Industry

BOPP (Biaxially Oriented Polypropylene) film is extensively used in packaging for its excellent clarity, moisture resistance, and printability, making it ideal for food wrap, labels, and flexible packaging that requires attractive visuals. CPP (Cast Polypropylene) film offers superior heat sealability, higher impact resistance, and better elongation properties, making it suitable for laminated packaging, heavy-duty bags, and applications requiring strong seals and flexibility. Both films are crucial in the packaging industry, with BOPP preferred for decorative and barrier qualities, while CPP is chosen for its mechanical strength and sealing performance.

Printability and Lamination Compatibility

BOPP (Biaxially Oriented Polypropylene) film offers superior printability due to its high gloss surface and excellent ink adhesion, making it a preferred choice for vibrant, high-quality graphics. CPP (Cast Polypropylene) film provides enhanced lamination compatibility with various adhesives, enabling stronger seals and improved package integrity in multilayer structures. Your packaging application benefits from selecting BOPP when sharp visuals are critical, while CPP excels in applications requiring robust lamination performance.

Cost Analysis: BOPP vs CPP

BOPP film typically offers a lower cost per unit compared to CPP due to its efficient production process and higher yield rates, making it a budget-friendly option for large-scale packaging. CPP film, while slightly more expensive, provides superior heat resistance and sealing properties that can reduce product loss and packaging failures, potentially lowering overall operational costs. Your choice between BOPP and CPP should consider both upfront material expenses and long-term durability impacts on packaging efficiency.

Environmental Impact and Recyclability

BOPP (Biaxially Oriented Polypropylene) films have a lower environmental impact due to their higher recyclability compared to CPP (Cast Polypropylene) films, which are less commonly recycled. BOPP's crystalline structure allows for efficient processing and reuse, making it more sustainable for packaging applications. Your choice of film can significantly influence waste management and sustainability efforts.

Market Trends and Regional Usage

BOPP (Biaxially Oriented Polypropylene) films dominate packaging markets in Asia-Pacific due to their excellent moisture barrier and clarity, driving high demand in food and labeling sectors. CPP (Cast Polypropylene) films see greater usage in Europe and North America, favored for their superior heat resistance and flexibility in lamination and sealing applications. Market trends indicate growing adoption of sustainable BOPP variants in emerging regions, while CPP maintains steady growth linked to increased flexible packaging consumption in developed markets.

Choosing the Right Film for Your Needs

BOPP film offers high clarity, excellent moisture resistance, and superior stiffness, making it ideal for packaging that demands strong printability and durability. CPP film provides greater flexibility, impact resistance, and softness, which suits applications requiring superior sealability and puncture resistance. You should select BOPP for visually appealing, rigid packaging and CPP when flexibility and easy heat sealing are your primary needs.

BOPP vs CPP (film types) Infographic

libmatt.com

libmatt.com