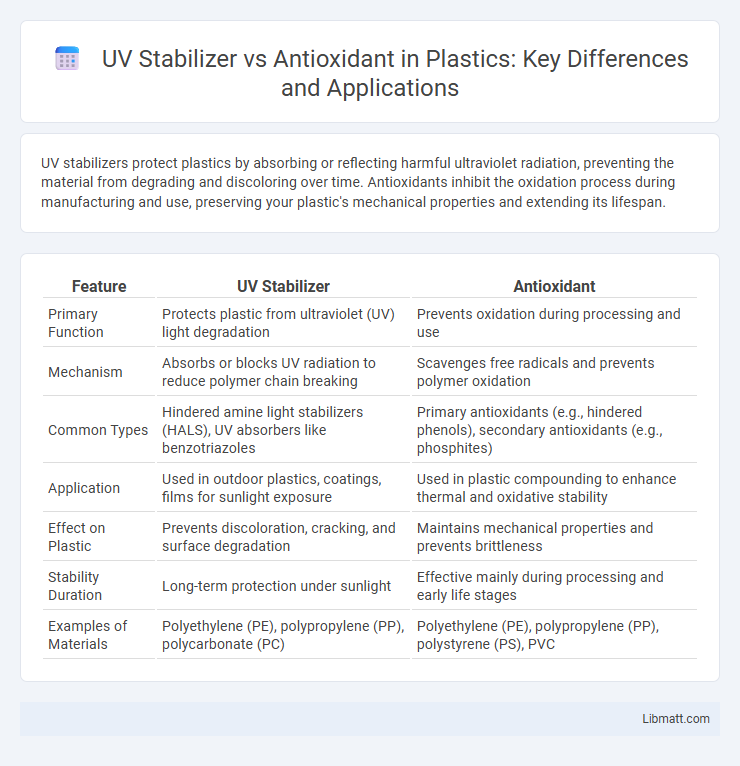

UV stabilizers protect plastics by absorbing or reflecting harmful ultraviolet radiation, preventing the material from degrading and discoloring over time. Antioxidants inhibit the oxidation process during manufacturing and use, preserving your plastic's mechanical properties and extending its lifespan.

Table of Comparison

| Feature | UV Stabilizer | Antioxidant |

|---|---|---|

| Primary Function | Protects plastic from ultraviolet (UV) light degradation | Prevents oxidation during processing and use |

| Mechanism | Absorbs or blocks UV radiation to reduce polymer chain breaking | Scavenges free radicals and prevents polymer oxidation |

| Common Types | Hindered amine light stabilizers (HALS), UV absorbers like benzotriazoles | Primary antioxidants (e.g., hindered phenols), secondary antioxidants (e.g., phosphites) |

| Application | Used in outdoor plastics, coatings, films for sunlight exposure | Used in plastic compounding to enhance thermal and oxidative stability |

| Effect on Plastic | Prevents discoloration, cracking, and surface degradation | Maintains mechanical properties and prevents brittleness |

| Stability Duration | Long-term protection under sunlight | Effective mainly during processing and early life stages |

| Examples of Materials | Polyethylene (PE), polypropylene (PP), polycarbonate (PC) | Polyethylene (PE), polypropylene (PP), polystyrene (PS), PVC |

Introduction to UV Stabilizers and Antioxidants in Plastics

UV stabilizers in plastics protect polymers from degradation caused by ultraviolet light exposure, enhancing material longevity by absorbing or dissipating harmful UV radiation. Antioxidants inhibit oxidation processes during polymer processing and service life, preventing color changes, loss of mechanical properties, and premature aging. Both stabilizers are critical in maintaining plastic performance, with UV stabilizers targeting light-induced damage and antioxidants focusing on thermal and oxidative degradation.

Chemical Mechanisms: How UV Stabilizers Work

UV stabilizers protect plastics by absorbing or reflecting harmful ultraviolet radiation, preventing the chain reactions that degrade polymer molecules. These stabilizers typically work through chemical mechanisms such as photostabilization, where they dissipate UV energy as heat, or by scavenging free radicals generated by UV exposure. Your plastic products maintain durability and color integrity longer when UV stabilizers effectively inhibit polymer breakdown caused by UV-induced photochemical reactions.

Antioxidants: Protecting Plastics from Oxidative Degradation

Antioxidants in plastics primarily prevent oxidative degradation by inhibiting free radical formation and chain reactions that cause polymer breakdown. These compounds extend the lifespan of plastics by stabilizing molecular structures exposed to heat and oxygen during processing and use. Unlike UV stabilizers, which specifically absorb or dissipate ultraviolet radiation, antioxidants focus on maintaining polymer integrity against thermal and oxidative stress.

Key Differences Between UV Stabilizers and Antioxidants

UV stabilizers protect plastics by absorbing or reflecting harmful ultraviolet radiation, preventing polymer degradation caused by sunlight exposure. Antioxidants inhibit oxidation processes by neutralizing free radicals generated during thermal or mechanical stress, extending the plastic's lifespan in various environments. Your choice between UV stabilizers and antioxidants depends on the specific environmental challenges your plastic product will face, ensuring optimal durability and performance.

Applications of UV Stabilizers in Plastic Products

UV stabilizers are essential in plastic products exposed to sunlight, such as outdoor furniture, automotive parts, and roofing materials, where they prevent degradation caused by ultraviolet radiation. These additives absorb or block UV light, preserving the polymer's mechanical properties, color, and overall durability. You ensure longer-lasting plastic items by selecting appropriate UV stabilizers tailored to specific environmental conditions and product uses.

Common Types of Antioxidants Used in Plastics

Common types of antioxidants used in plastics include hindered phenols, phosphites, and thioethers, each providing protection against oxidative degradation during processing and service life. Hindered phenols scavenge free radicals, phosphites act as secondary antioxidants by decomposing hydroperoxides, and thioethers enhance long-term thermal stability. Your choice of antioxidant depends on the plastic type and desired durability, as these additives work synergistically to maintain polymer integrity under heat and environmental stress.

Synergistic Effects: Combining UV Stabilizers and Antioxidants

Combining UV stabilizers and antioxidants in plastics enhances durability by providing synergistic effects that protect against both UV radiation and oxidative degradation. UV stabilizers absorb or block harmful UV rays, preventing polymer chain scission, while antioxidants inhibit thermal and oxidative damage by scavenging free radicals. This dual protection extends the lifespan and maintains the mechanical properties of Your plastic products, making them more resistant to environmental stressors.

Factors Influencing the Selection of Additives in Plastics

Factors influencing the selection of UV stabilizers versus antioxidants in plastics include the specific environmental conditions the material will face, such as exposure to sunlight, oxygen, and heat. UV stabilizers are essential for preventing polymer degradation caused by ultraviolet radiation, while antioxidants protect against thermal and oxidative damage during processing and service life. Your choice should consider the plastic type, intended application, and longevity requirements to ensure optimal performance and durability.

Impact on Plastic Durability and Service Life

UV stabilizers in plastics primarily protect against degradation caused by ultraviolet radiation, significantly enhancing plastic durability by preventing color fading, cracking, and surface embrittlement. Antioxidants inhibit oxidative degradation during processing and use, preserving the polymer's mechanical properties and extending service life by reducing chain scission and discoloration. Combined use of UV stabilizers and antioxidants ensures optimal protection against environmental stressors, leading to prolonged plastic performance and longevity.

Future Trends in Plastic Additive Technologies

Future trends in plastic additive technologies emphasize the development of multifunctional additives that combine UV stabilizers and antioxidants to enhance durability and environmental resistance in polymers. Advanced nanotechnology enables the creation of hybrid additives with improved dispersion and synergistic effects, extending the lifespan of plastics exposed to harsh UV radiation and oxidative conditions. Biodegradable and sustainable UV stabilizers and antioxidants are also gaining traction, aligning with global efforts to reduce plastic waste and environmental impact.

UV stabilizer vs antioxidant (in plastics) Infographic

libmatt.com

libmatt.com