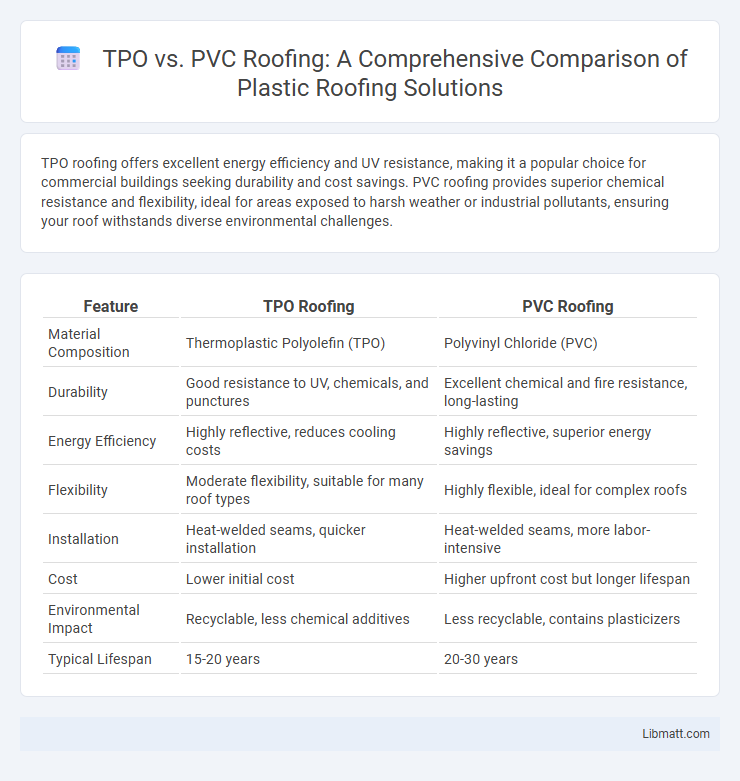

TPO roofing offers excellent energy efficiency and UV resistance, making it a popular choice for commercial buildings seeking durability and cost savings. PVC roofing provides superior chemical resistance and flexibility, ideal for areas exposed to harsh weather or industrial pollutants, ensuring your roof withstands diverse environmental challenges.

Table of Comparison

| Feature | TPO Roofing | PVC Roofing |

|---|---|---|

| Material Composition | Thermoplastic Polyolefin (TPO) | Polyvinyl Chloride (PVC) |

| Durability | Good resistance to UV, chemicals, and punctures | Excellent chemical and fire resistance, long-lasting |

| Energy Efficiency | Highly reflective, reduces cooling costs | Highly reflective, superior energy savings |

| Flexibility | Moderate flexibility, suitable for many roof types | Highly flexible, ideal for complex roofs |

| Installation | Heat-welded seams, quicker installation | Heat-welded seams, more labor-intensive |

| Cost | Lower initial cost | Higher upfront cost but longer lifespan |

| Environmental Impact | Recyclable, less chemical additives | Less recyclable, contains plasticizers |

| Typical Lifespan | 15-20 years | 20-30 years |

Introduction to TPO and PVC Roofing

TPO (Thermoplastic Olefin) and PVC (Polyvinyl Chloride) roofing are popular single-ply membrane roofing systems known for their durability and energy efficiency. TPO roofing offers excellent resistance to UV rays, chemical exposure, and punctures, making it ideal for commercial and industrial buildings. PVC roofing provides superior fire resistance and chemical tolerance, often chosen for facilities requiring stringent safety standards and demanding environments.

Key Differences Between TPO and PVC Roofing

TPO roofing features a single-ply membrane made from a blend of polypropylene and ethylene-propylene rubber, offering flexibility and cost-effectiveness, while PVC roofing consists of a single-ply membrane made from polyvinyl chloride, known for its durability and chemical resistance. TPO membranes typically provide better UV resistance and heat weldability, making them easier to install and repair, whereas PVC roofing excels in resisting chemicals, fire, and punctures, suitable for industrial environments. Your choice between TPO and PVC roofing should consider factors such as budget, climate, and exposure to chemicals, balancing cost and performance for the best long-term value.

Material Composition and Properties

TPO roofing consists of a single-ply membrane made from a blend of polypropylene and ethylene-propylene rubber, offering excellent UV resistance and flexibility. PVC roofing is composed of polyvinyl chloride compounded with plasticizers and stabilizers, providing superior chemical resistance and durability. Both materials deliver strong waterproofing capabilities, but TPO generally offers better heat-welded seam strength, while PVC excels in resistance to oils and chemicals.

Durability and Lifespan Comparison

TPO roofing offers excellent durability with high resistance to UV rays, punctures, and chemical exposure, typically lasting 15-20 years, while PVC roofing boasts superior longevity, often exceeding 20-30 years due to its exceptional flexibility and resistance to fire and harsh weather. Both materials require minimal maintenance, but PVC's enhanced resilience against extreme temperatures makes it a preferred choice for long-term roof performance. Your decision should weigh the slightly longer lifespan and durability benefits of PVC against the cost-effectiveness and solid protection provided by TPO.

Energy Efficiency and Reflectivity

TPO roofing offers superior energy efficiency with its highly reflective white surface, reducing cooling costs by reflecting UV rays effectively. PVC roofing also provides strong reflectivity, but TPO generally excels in minimizing heat absorption, enhancing your building's overall thermal performance. Both materials contribute to sustainable roofing solutions, but TPO often leads in lowering energy consumption through advanced reflectivity and heat resistance.

Installation Process and Techniques

TPO roofing features a heat-welded seam installation process that ensures strong, watertight bonds ideal for commercial applications, while PVC roofing uses solvent welding techniques for seams, providing excellent chemical and fire resistance. Both materials are installed over new or existing roofing substrates, with TPO typically requiring specialized hot-air welding equipment and PVC needing careful solvent application for durable seams. Proper surface preparation and skilled labor are critical for achieving long-lasting, leak-proof roofs with either TPO or PVC membranes.

Weather Resistance and Climate Suitability

TPO roofing offers excellent weather resistance with high reflectivity and strong UV protection, making it ideal for hot, sunny climates. PVC roofing excels in chemical resistance and can withstand harsh weather conditions, including heavy rain and wind, suitable for coastal and industrial regions. Both materials provide durability, but TPO is preferred for energy efficiency, while PVC is favored for superior resistance to harsh chemical exposure.

Maintenance Requirements and Costs

TPO roofing generally requires less maintenance due to its resistance to UV rays and chemical exposure, leading to lower overall upkeep costs compared to PVC roofing. PVC roofing, while durable and resistant to fire and chemicals, may involve higher maintenance expenses because of its susceptibility to punctures and seams needing regular inspection and repair. Both materials offer cost-effective solutions, but TPO's maintenance profile often results in reduced long-term expenditures.

Environmental Impact and Sustainability

TPO roofing is often favored for its energy efficiency due to its reflective surface, which reduces cooling costs and minimizes urban heat island effects, contributing to greater environmental sustainability. PVC roofing, while durable and recyclable, involves chlorine in its production, raising concerns about toxic emissions and environmental impact during manufacturing and disposal. Both materials offer recyclability options, but TPO's lower environmental toxicity and better energy performance generally position it as the more eco-friendly roofing choice.

Choosing the Right Roofing: TPO vs PVC

TPO roofing offers excellent energy efficiency with high reflectivity and UV resistance, making it ideal for commercial buildings in hot climates. PVC roofing provides superior chemical resistance and durability against harsh weather conditions, often favored in industrial settings with exposure to oils and solvents. Evaluating factors such as climate, building use, and long-term maintenance costs is crucial when choosing between TPO and PVC roofing systems.

TPO vs PVC Roofing Infographic

libmatt.com

libmatt.com