Mold temperature controls the cooling rate and final quality of the molded part, while barrel temperature affects the melting and flow properties of the plastic material during injection. Adjusting both temperatures accurately ensures optimal part integrity and minimizes defects in your injection molding process.

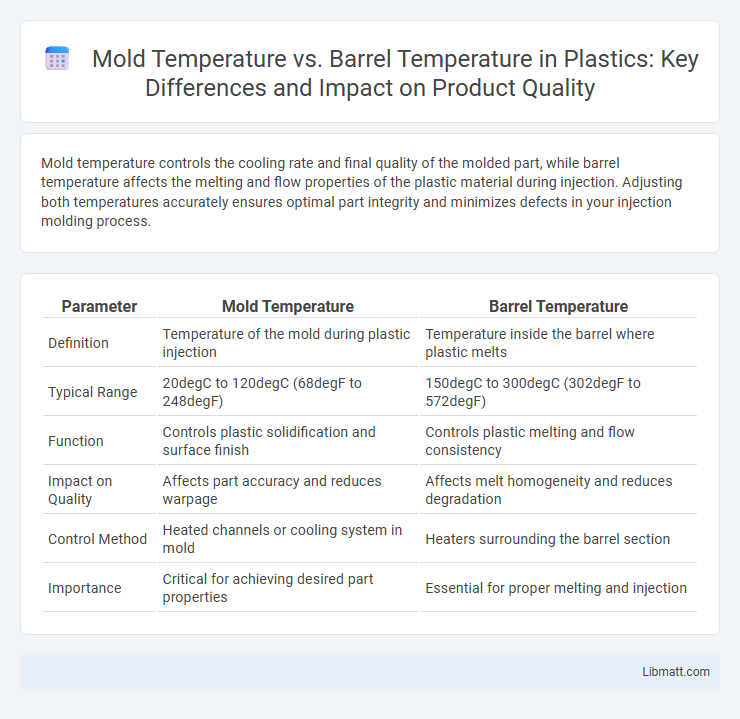

Table of Comparison

| Parameter | Mold Temperature | Barrel Temperature |

|---|---|---|

| Definition | Temperature of the mold during plastic injection | Temperature inside the barrel where plastic melts |

| Typical Range | 20degC to 120degC (68degF to 248degF) | 150degC to 300degC (302degF to 572degF) |

| Function | Controls plastic solidification and surface finish | Controls plastic melting and flow consistency |

| Impact on Quality | Affects part accuracy and reduces warpage | Affects melt homogeneity and reduces degradation |

| Control Method | Heated channels or cooling system in mold | Heaters surrounding the barrel section |

| Importance | Critical for achieving desired part properties | Essential for proper melting and injection |

Introduction to Mold Temperature vs Barrel Temperature

Mold temperature and barrel temperature are critical parameters in the injection molding process, directly impacting product quality and cycle time. Mold temperature controls the cooling rate of the molten plastic, affecting surface finish and dimensional stability, while barrel temperature regulates the melting and flow characteristics of the polymer inside the extruder. Understanding the precise relationship between mold temperature and barrel temperature helps you optimize processing conditions for consistent and high-quality molded parts.

Understanding Mold Temperature in Injection Molding

Mold temperature in injection molding significantly influences the cooling rate, dimensional stability, and surface finish of the molded parts. Maintaining a precise mold temperature, typically between 40degC and 80degC depending on the polymer type, ensures optimal polymer flow and reduces defects such as warpage and sink marks. Barrel temperature controls the polymer melt viscosity, while mold temperature governs the solidification process and cycle time efficiency, making both critical for achieving high-quality injection molded components.

The Role of Barrel Temperature in Polymer Processing

Barrel temperature plays a critical role in polymer processing by directly influencing the melting, viscosity, and flow behavior of the polymer melt. Maintaining an optimal barrel temperature ensures uniform melting and consistent material properties, which reduces defects like incomplete filling or material degradation. Precise control of barrel temperature enhances product quality and process efficiency, making it essential for achieving targeted mechanical and aesthetic characteristics in molded parts.

Key Differences Between Mold and Barrel Temperatures

Mold temperature controls the cooling rate and surface finish of the molded part, typically maintained between 20degC to 120degC depending on the material. Barrel temperature refers to the temperature inside the injection molding machine barrel, usually ranging from 150degC to 280degC to properly melt the plastic resin. The key difference lies in their functions: mold temperature affects part quality and cycle time, while barrel temperature ensures proper melting and flow of the polymer during injection.

Effects of Mold Temperature on Product Quality

Mold temperature significantly influences product quality by affecting the cooling rate, crystallinity, and dimensional stability of the molded part. Higher mold temperatures improve surface finish and reduce residual stresses, leading to better mechanical properties and reduced warpage. Your choice of optimal mold temperature ensures consistent quality and minimizes defects such as sink marks and weld lines during injection molding.

Impact of Barrel Temperature on Material Flow

Barrel temperature critically influences material flow during injection molding by affecting polymer viscosity and melting uniformity. Higher barrel temperatures reduce viscosity, enabling smoother and faster flow through the mold channels, which enhances filling accuracy and reduces flow marks. Optimal barrel temperature settings ensure consistent material flow, minimizing defects and improving the quality of the molded part.

Optimizing Mold and Barrel Temperatures for Efficiency

Optimizing mold and barrel temperatures is crucial for enhancing injection molding efficiency by ensuring precise control over material flow and cooling rates. Maintaining an optimal barrel temperature range, typically between 200degC and 300degC depending on the polymer, facilitates uniform melting and reduces degradation risks, while mold temperatures are often kept between 40degC and 80degC to balance cooling time and surface finish quality. Fine-tuning these parameters improves cycle times, reduces defects like warping and sink marks, and maximizes overall production throughput.

Common Issues Caused by Temperature Imbalances

Temperature imbalances between mold temperature and barrel temperature commonly cause defects such as warping, incomplete filling, and surface blemishes in injection molding. Excessive mold temperature paired with low barrel temperature can lead to poor polymer fusion, while high barrel temperature with low mold temperature often results in excessive shrinkage and internal stresses. Maintaining an optimal temperature balance is crucial for ensuring dimensional accuracy and enhancing overall part quality.

Best Practices for Temperature Control in Injection Molding

Maintaining optimal mold temperature and barrel temperature is crucial for consistent injection molding quality and cycle efficiency. Best practices include setting mold temperature according to the material's thermal properties, typically between 50-120degC for thermoplastics, while barrel temperature zones should be precisely controlled to avoid degradation, commonly ranging from 180-280degC depending on resin type. You can improve part quality and reduce defects by using calibrated thermocouples, staged heating zones in the barrel, and real-time monitoring systems to ensure stable temperature control throughout the molding process.

Conclusion: Achieving Balance for Optimal Results

Achieving the optimal balance between mold temperature and barrel temperature is crucial for enhancing product quality and process efficiency in injection molding. Proper mold temperature ensures uniform cooling and minimizes defects such as warping, while maintaining the right barrel temperature guarantees consistent material flow and melt viscosity. Your ability to fine-tune both parameters directly impacts cycle time, surface finish, and overall part performance.

Mold Temperature vs Barrel Temperature Infographic

libmatt.com

libmatt.com