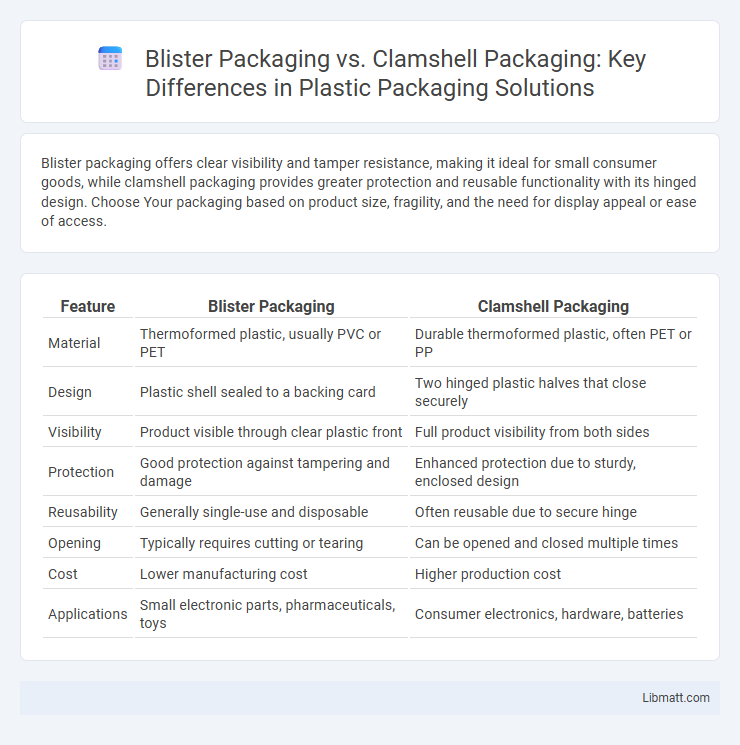

Blister packaging offers clear visibility and tamper resistance, making it ideal for small consumer goods, while clamshell packaging provides greater protection and reusable functionality with its hinged design. Choose Your packaging based on product size, fragility, and the need for display appeal or ease of access.

Table of Comparison

| Feature | Blister Packaging | Clamshell Packaging |

|---|---|---|

| Material | Thermoformed plastic, usually PVC or PET | Durable thermoformed plastic, often PET or PP |

| Design | Plastic shell sealed to a backing card | Two hinged plastic halves that close securely |

| Visibility | Product visible through clear plastic front | Full product visibility from both sides |

| Protection | Good protection against tampering and damage | Enhanced protection due to sturdy, enclosed design |

| Reusability | Generally single-use and disposable | Often reusable due to secure hinge |

| Opening | Typically requires cutting or tearing | Can be opened and closed multiple times |

| Cost | Lower manufacturing cost | Higher production cost |

| Applications | Small electronic parts, pharmaceuticals, toys | Consumer electronics, hardware, batteries |

Overview of Blister Packaging and Clamshell Packaging

Blister packaging consists of a pre-formed plastic cavity sealed to a backing card, offering visibility and protection for small consumer goods, pharmaceuticals, and electronics. Clamshell packaging features a hinged, molded plastic container that encloses products completely, providing durability and tamper resistance for tools, toys, and hardware. Both packaging types enhance product presentation and security but differ in structure and application based on product size and display needs.

Key Differences Between Blister and Clamshell Packaging

Blister packaging typically consists of a pre-formed plastic cavity sealed to a backing card, offering clear product visibility and cost-effective mass production. Clamshell packaging involves two plastic halves joined by a hinge, providing enhanced product protection and tamper resistance with easy resealability. The key differences lie in material flexibility, security level, and user convenience, with blisters favored for lightweight items and clamshells chosen for high-value or fragile products.

Material Composition and Sustainability

Blister packaging typically consists of a pre-formed plastic cavity, often made from PVC or PET, combined with a paperboard backing, creating challenges for recycling due to mixed materials. Clamshell packaging is usually made entirely of clear PET or polypropylene, allowing easier recycling and improved material separation compared to blister packs. Sustainable options for both packaging types include using biodegradable plastics or recycled materials, significantly reducing environmental impact and supporting circular economy goals.

Protection and Product Visibility

Blister packaging offers excellent product visibility through its clear plastic covering, allowing customers to easily inspect the item while providing strong protection against tampering and environmental factors. Clamshell packaging also ensures robust protection with its hinged design and durable plastic, but its opaque or semi-transparent nature can limit visibility compared to blister packs. You can choose blister packaging for enhanced display appeal and clamshell packaging for more secure containment of heavier or bulkier products.

Cost Efficiency and Production Processes

Blister packaging typically offers higher cost efficiency due to its lower material costs and faster production cycles, making it ideal for high-volume manufacturing. Clamshell packaging involves more complex tooling and assembly processes, resulting in higher production costs but increased product protection and visibility. Both methods require specific machinery, with blister packaging favoring thermoforming equipment and clamshell packaging using form-fill-seal machines, impacting overall production scalability.

Tamper Evidence and Security Features

Blister packaging offers tamper evidence through sealed cavities that show visible damage when opened, enhancing product security and preventing contamination. Clamshell packaging provides robust tamper evidence with secure locking mechanisms and seals that reveal unauthorized access. Both packaging types safeguard product integrity but clamshells often deliver higher security with their rigid structure and integrated locking features.

Customization and Branding Potential

Blister packaging offers moderate customization options with clear visibility of the product, supporting vibrant printed inserts for branding that enhance consumer appeal. Clamshell packaging provides superior customization flexibility, allowing designers to incorporate unique shapes, textures, and secure locking mechanisms that elevate brand recognition and product differentiation. Both packaging types enable the use of high-quality graphics, but clamshells generally allow for more innovative branding techniques and tactile consumer interaction.

Consumer Experience and Usability

Blister packaging offers a clear view of the product, allowing consumers to easily identify contents while providing tamper-evident protection that enhances security and freshness. Clamshell packaging often features a hinged design that allows for easy opening and resealing, improving convenience and reducing product damage during handling. Your choice between blister and clamshell packaging will directly impact user satisfaction, as blister packs prioritize visibility and tamper resistance, whereas clamshells emphasize accessibility and reusability.

Market Applications and Industry Suitability

Blister packaging excels in pharmaceuticals and small consumer electronics due to its tamper-evident and product visibility features, ensuring safety and ease of use in retail environments. Clamshell packaging suits larger items in hardware, toys, and electronics industries by providing robust protection and product display while allowing for resealability. Your choice depends on the specific industry requirements, product size, and the need for security versus convenience.

Choosing the Right Packaging for Your Product

Choosing the right packaging for your product depends on factors like visibility, protection, and usability. Blister packaging offers excellent product visibility with a clear, sealed cavity ideal for small items, while clamshell packaging provides sturdy protection and easy resealing, suitable for heavier or bulkier products. Your decision should balance product presentation, security, and customer convenience to maximize appeal and functionality.

Blister packaging vs clamshell packaging Infographic

libmatt.com

libmatt.com