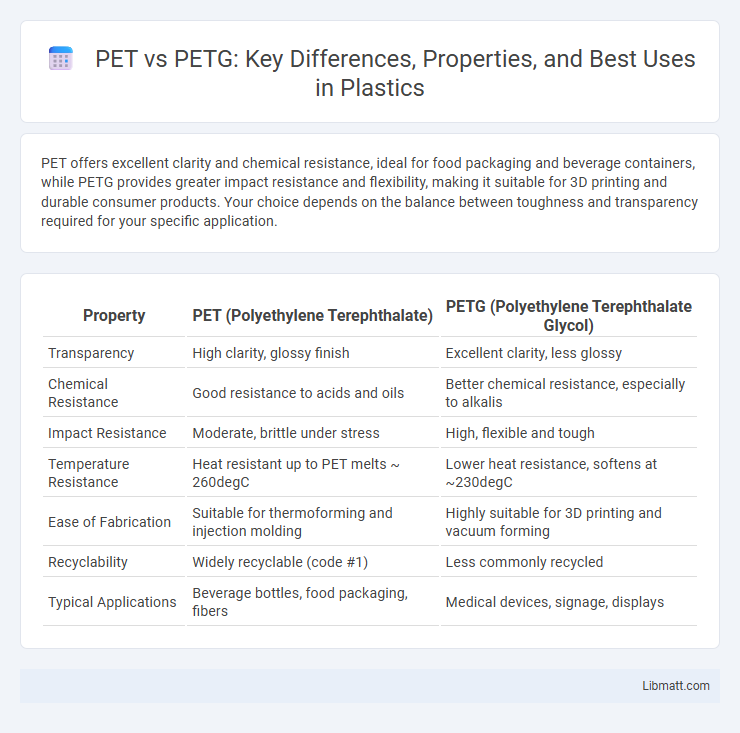

PET offers excellent clarity and chemical resistance, ideal for food packaging and beverage containers, while PETG provides greater impact resistance and flexibility, making it suitable for 3D printing and durable consumer products. Your choice depends on the balance between toughness and transparency required for your specific application.

Table of Comparison

| Property | PET (Polyethylene Terephthalate) | PETG (Polyethylene Terephthalate Glycol) |

|---|---|---|

| Transparency | High clarity, glossy finish | Excellent clarity, less glossy |

| Chemical Resistance | Good resistance to acids and oils | Better chemical resistance, especially to alkalis |

| Impact Resistance | Moderate, brittle under stress | High, flexible and tough |

| Temperature Resistance | Heat resistant up to PET melts ~ 260degC | Lower heat resistance, softens at ~230degC |

| Ease of Fabrication | Suitable for thermoforming and injection molding | Highly suitable for 3D printing and vacuum forming |

| Recyclability | Widely recyclable (code #1) | Less commonly recycled |

| Typical Applications | Beverage bottles, food packaging, fibers | Medical devices, signage, displays |

Introduction to PET and PETG

PET, or polyethylene terephthalate, is a widely used thermoplastic polymer known for its excellent strength, chemical resistance, and clarity, commonly utilized in packaging and beverage bottles. PETG, a glycol-modified version of PET, offers enhanced impact resistance, improved flexibility, and better ease of fabrication, making it ideal for 3D printing, medical devices, and food packaging. Both materials share similar chemical structures but differ in thermal and mechanical properties due to the glycol modification in PETG, which disrupts crystallization and improves durability.

Chemical Composition Differences

PET (Polyethylene Terephthalate) is a thermoplastic polymer made from terephthalic acid and ethylene glycol, known for its crystalline structure and high tensile strength. PETG (Glycol-modified PET) incorporates glycol during polymerization, which disrupts crystallization, resulting in a more amorphous and flexible material with enhanced impact resistance. The glycol modification in PETG lowers melting temperature and improves processability, making it suitable for applications requiring clarity and durability.

Physical Properties Comparison

PET exhibits higher tensile strength and stiffness compared to PETG, making it suitable for applications requiring rigidity and durability. PETG offers greater impact resistance and flexibility, along with improved clarity and chemical resistance, which is advantageous for packaging and medical devices. The enhanced thermal stability of PET supports higher temperature uses, whereas PETG's lower glass transition temperature facilitates easier thermoforming and printing processes.

Applications of PET

PET is widely used in packaging applications due to its excellent strength, clarity, and gas barrier properties, making it ideal for bottled beverages, food containers, and cosmetic packaging. Your manufacturing processes benefit from PET's recyclability and thermal stability, which support sustainable production and repeated use. PET's wide adoption in the textile industry, where it is transformed into polyester fibers, underscores its versatility beyond packaging.

Applications of PETG

PETG is widely used in applications requiring durability and flexibility, such as medical devices, food packaging, and 3D printing prototypes. Its chemical resistance and impact strength make it ideal for protective covers, display cases, and signage. You will find PETG favored for clear, lightweight containers and components that must withstand daily handling and moisture exposure.

Durability and Strength

PETG offers enhanced durability and impact resistance compared to standard PET, making it more suitable for applications requiring toughness and flexibility. While PET is rigid and brittle under stress, PETG combines clarity with improved tensile strength and elongation, reducing the risk of cracking or breaking. These strength characteristics position PETG as a preferred material in industries like packaging and 3D printing where durability is critical.

Printability for 3D Printing

PETG offers superior printability compared to PET due to its balanced flexibility and chemical resistance, making it less prone to warping and cracking during 3D printing. PET requires higher printing temperatures and precise cooling control to avoid issues like poor layer adhesion and brittleness. PETG's lower printing temperature range (220-250degC) and strong layer bonding enhance printing reliability and surface finish quality in 3D printing applications.

Environmental Impact and Recycling

PET (Polyethylene Terephthalate) is widely recycled and has a well-established recycling infrastructure, making it more environmentally favorable due to its recyclability and lower contamination levels compared to PETG. PETG (Polyethylene Terephthalate Glycol) poses challenges in recycling because it does not easily blend with PET streams, often leading to increased contamination and reduced quality in recycled materials. Both materials are derived from petrochemicals, but PET's compatibility with existing recycling systems enhances its sustainability profile over PETG in environmental impact assessments.

Cost and Availability

PET (Polyethylene Terephthalate) is generally more cost-effective and widely available due to its extensive use in beverage bottles and packaging industries, making it easier to source in large quantities. PETG (Glycol-modified PET), while slightly more expensive, offers improved durability and flexibility, but its availability is more limited as it is primarily used in specialized applications like 3D printing and medical devices. Bulk purchasing of PET can reduce costs further, whereas PETG often involves higher pricing because of its modified chemical properties and niche production scale.

Which Material to Choose?

PET offers excellent chemical resistance and durability, making it ideal for food packaging and beverage containers. PETG provides greater impact resistance and flexibility, enhancing suitability for 3D printing and medical applications. Choose PET for rigidity and clarity, while PETG is preferable when ease of fabrication and toughness are priorities.

PET vs PETG Infographic

libmatt.com

libmatt.com