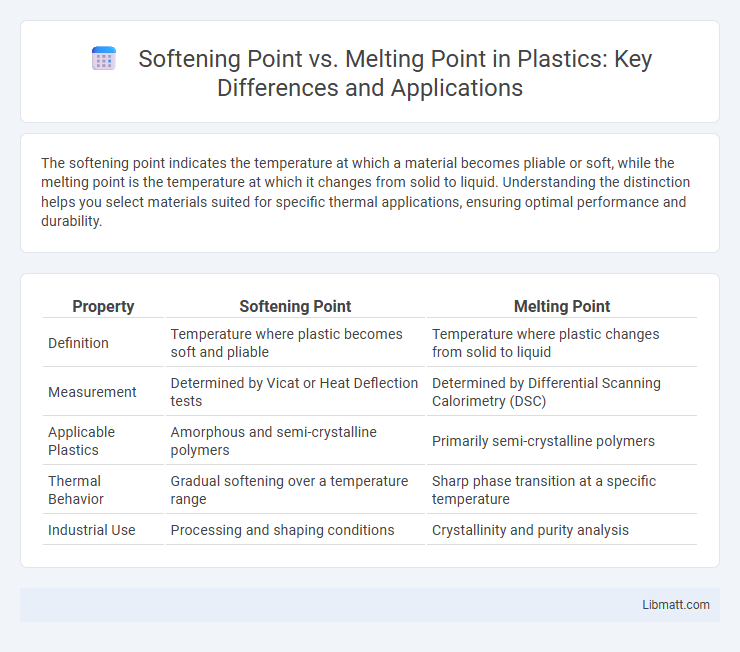

The softening point indicates the temperature at which a material becomes pliable or soft, while the melting point is the temperature at which it changes from solid to liquid. Understanding the distinction helps you select materials suited for specific thermal applications, ensuring optimal performance and durability.

Table of Comparison

| Property | Softening Point | Melting Point |

|---|---|---|

| Definition | Temperature where plastic becomes soft and pliable | Temperature where plastic changes from solid to liquid |

| Measurement | Determined by Vicat or Heat Deflection tests | Determined by Differential Scanning Calorimetry (DSC) |

| Applicable Plastics | Amorphous and semi-crystalline polymers | Primarily semi-crystalline polymers |

| Thermal Behavior | Gradual softening over a temperature range | Sharp phase transition at a specific temperature |

| Industrial Use | Processing and shaping conditions | Crystallinity and purity analysis |

Introduction to Softening Point and Melting Point

The softening point is the temperature at which a material, typically a polymer or glass, begins to deform or soften without fully melting, indicating a transition from a rigid to a pliable state. The melting point is the precise temperature at which a solid turns into a liquid, marking the phase transition with complete molecular rearrangement. Understanding the distinction between softening point and melting point is crucial in materials science for applications requiring thermal stability and precise temperature control.

Definition of Softening Point

Softening point is the temperature at which a material, such as a polymer or glass, begins to deform or flow under a specific load, indicating the transition from a rigid to a pliable state. Unlike the melting point, which is a precise temperature where a solid turns to liquid, the softening point is often a range and depends on factors like composition and pressure. Understanding the softening point helps you determine the heat resistance and processability of materials in applications like manufacturing and material selection.

Definition of Melting Point

The melting point is the precise temperature at which a solid turns into a liquid under standard atmospheric pressure, indicating a well-defined phase transition. Unlike the softening point, which marks the temperature range where a material begins to soften and deform, the melting point represents a sharp change from solid to liquid state. Understanding your material's melting point is crucial for applications requiring exact thermal thresholds, such as in manufacturing and quality control.

Key Differences Between Softening and Melting Points

The softening point refers to the temperature at which a material begins to deform or become pliable, while the melting point is the precise temperature at which a solid turns into a liquid. Softening point is commonly used for polymers, resins, and glasses to describe gradual softening behavior, whereas melting point is a sharp, well-defined property for crystalline substances. Understanding these differences is crucial in materials science for selecting appropriate thermal processing methods and ensuring product performance.

Importance in Material Science and Engineering

Softening point and melting point are critical thermal properties used in material science and engineering to determine how materials behave under temperature variations, directly influencing their selection for specific applications. Understanding your material's softening point helps predict deformation under heat before reaching a fully liquid state, while the melting point indicates the exact temperature at which the solid becomes liquid. Accurate knowledge of both points ensures optimal performance and safety in manufacturing processes such as molding, welding, and thermal treatment.

Methods for Measuring Softening Point

Softening point measurement methods include the Ring and Ball method, which determines the temperature at which a sample softens enough to allow a steel ball to fall a specific distance. The Vicat Softening Point test uses a standardized needle to record the temperature at which a material starts to deform under a specified load. Other techniques such as the Heat Deflection Temperature (HDT) provide complementary data by measuring the deformation of polymers under load at increasing temperature.

Techniques for Determining Melting Point

Techniques for determining melting point include capillary tube methods, differential scanning calorimetry (DSC), and hot-stage microscopy, each providing precise temperature measurement where a solid transitions to liquid. Capillary tube methods involve observing the temperature at which a sample inside a thin tube melts under controlled heating. DSC measures heat flow changes, accurately identifying melting points by detecting endothermic peaks during phase transitions.

Applications in Industry

The softening point is critical in industries such as asphalt production and polymer processing, where materials must maintain shape under heat without fully melting. The melting point is essential in metallurgy and pharmaceuticals to ensure precise phase transitions for alloy formation and drug purity. Understanding both properties allows manufacturers to select materials with appropriate thermal behavior for coatings, adhesives, and packaging applications.

Factors Affecting Softening and Melting Points

Softening point and melting point are influenced by molecular structure, intermolecular forces, and impurities within a material. Polymers typically show a softening point due to gradual phase change, while crystalline solids exhibit a sharp melting point caused by uniform molecular bonds breaking simultaneously. Understanding these factors helps you accurately predict material behavior under heat for applications requiring thermal stability.

Summary: Choosing the Right Parameter

Softening point and melting point are critical thermal properties used to characterize material behavior under heat. The melting point is a precise temperature at which a solid turns to liquid, essential for pure substances, while the softening point indicates the temperature range where materials, especially polymers and bitumen, begin to deform without melting. Selecting the appropriate parameter depends on the material type and application, with melting point preferred for crystalline solids and softening point for amorphous or composite materials requiring thermal deformation insight.

Softening Point vs Melting Point Infographic

libmatt.com

libmatt.com