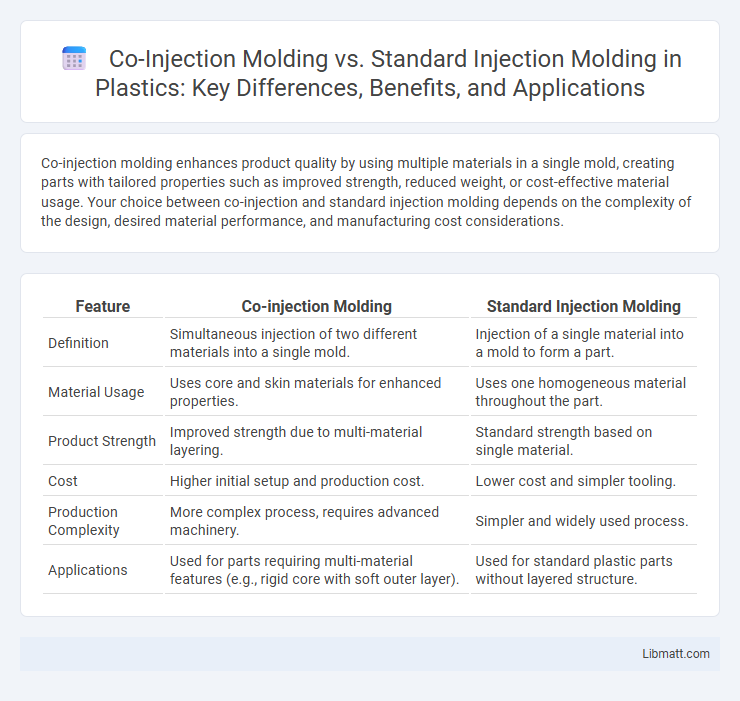

Co-injection molding enhances product quality by using multiple materials in a single mold, creating parts with tailored properties such as improved strength, reduced weight, or cost-effective material usage. Your choice between co-injection and standard injection molding depends on the complexity of the design, desired material performance, and manufacturing cost considerations.

Table of Comparison

| Feature | Co-injection Molding | Standard Injection Molding |

|---|---|---|

| Definition | Simultaneous injection of two different materials into a single mold. | Injection of a single material into a mold to form a part. |

| Material Usage | Uses core and skin materials for enhanced properties. | Uses one homogeneous material throughout the part. |

| Product Strength | Improved strength due to multi-material layering. | Standard strength based on single material. |

| Cost | Higher initial setup and production cost. | Lower cost and simpler tooling. |

| Production Complexity | More complex process, requires advanced machinery. | Simpler and widely used process. |

| Applications | Used for parts requiring multi-material features (e.g., rigid core with soft outer layer). | Used for standard plastic parts without layered structure. |

Introduction to Injection Molding Technologies

Injection molding technologies encompass various methods for producing intricate plastic components, with standard injection molding involving the injection of molten polymer into a mold cavity to create a single-material part. Co-injection molding, also known as sandwich molding, introduces multiple polymer materials during the molding process, allowing for parts with enhanced properties such as improved strength, weight reduction, or cost efficiency. Your choice between these technologies depends on specific application requirements like material performance, part complexity, and production volume.

What is Standard Injection Molding?

Standard injection molding is a manufacturing process where molten plastic is injected into a single mold cavity to form a solid part. It involves heating thermoplastic material until it becomes liquid, then using pressure to fill the mold, followed by cooling and solidification. This method is ideal for producing high volumes of identical plastic components with consistent quality and dimensional accuracy.

Understanding Co-injection Molding

Co-injection molding is an advanced plastic manufacturing process that uses two different materials injected sequentially into a single mold, forming a multi-layered part with enhanced properties such as improved surface finish, mechanical strength, and cost efficiency. Unlike standard injection molding, which involves a single material, co-injection molding allows for combinations of materials like a durable core with an aesthetic outer layer, optimizing functionality and reducing material usage. This technique is widely used in automotive, packaging, and consumer goods industries for producing complex, lightweight, and cost-effective components.

Key Differences Between Co-injection and Standard Injection Molding

Co-injection molding uses two different materials injected sequentially or simultaneously to combine their properties, enhancing functionality and reducing costs, while standard injection molding employs a single material injection. Co-injection allows for improved surface finish, better mechanical performance, and use of recycled or lower-cost core materials, whereas standard molding is simpler and faster but limits material versatility. Understanding these key differences helps you select the optimal molding process based on product requirements, cost constraints, and material performance needs.

Material Compatibility in Both Processes

Co-injection molding utilizes two different materials injected sequentially or simultaneously to create a part with enhanced properties, allowing compatibility between materials such as rigid cores and soft skins, which standard injection molding cannot achieve with a single material melt. Standard injection molding relies on one homogenous material, limiting the ability to combine properties like strength and flexibility within the same component. Understanding material compatibility in co-injection molding enables your design to exploit dual-material advantages for optimized performance, while standard injection molding remains ideal for uniform material requirements.

Advantages of Co-injection Molding

Co-injection molding offers significant advantages over standard injection molding by combining multiple materials in a single process, which enhances part performance and cost-efficiency. This technique reduces the use of expensive or specialized materials by sandwiching them between layers of more economical polymers, improving mechanical properties, and enabling complex part designs with tailored functionality. You benefit from greater design flexibility, improved surface finish, and reduced cycle times, making co-injection molding ideal for producing lightweight, durable components in automotive, packaging, and consumer goods industries.

Limitations of Co-injection Molding

Co-injection molding faces limitations such as increased tooling complexity and higher initial costs compared to standard injection molding. The process may also encounter challenges with material compatibility, leading to potential delamination or weak bonding between layers. Understanding these constraints helps you decide when co-injection molding is suitable for your manufacturing needs.

Common Applications of Co-injection vs Standard Molding

Co-injection molding is commonly used for producing multi-layered products such as fuel tanks, automotive parts, and packaging containers, where material savings and enhanced barrier properties are essential. Standard injection molding is typically applied for manufacturing single-material components like household items, toys, and simple mechanical parts with uniform material properties. Your choice between these techniques depends on the complexity, cost-efficiency, and specific performance requirements of the final product.

Cost Comparison and Production Efficiency

Co-injection molding typically reduces material costs by combining expensive and cheaper polymers, optimizing resource use compared to standard injection molding's single-material approach. Production efficiency in co-injection molding increases through shorter cycle times and improved part quality, minimizing waste and post-processing. You can achieve lower overall production expenses while maintaining high output rates by selecting co-injection molding for complex or multi-material components.

Choosing the Right Molding Process for Your Project

Co-injection molding offers enhanced material properties, such as improved surface finish and structural integrity, by combining two different polymers in a single process, whereas standard injection molding typically involves a single material, which may limit design flexibility. Your choice depends on the project's requirements for cost-efficiency, mechanical strength, and aesthetic quality, with co-injection being ideal for complex parts that demand multi-material benefits and standard molding suited for simpler, cost-sensitive applications. Understanding the trade-offs in material usage, cycle time, and equipment costs helps in selecting the optimal molding technique to meet your product specifications.

Co-injection Molding vs Standard Injection Molding Infographic

libmatt.com

libmatt.com