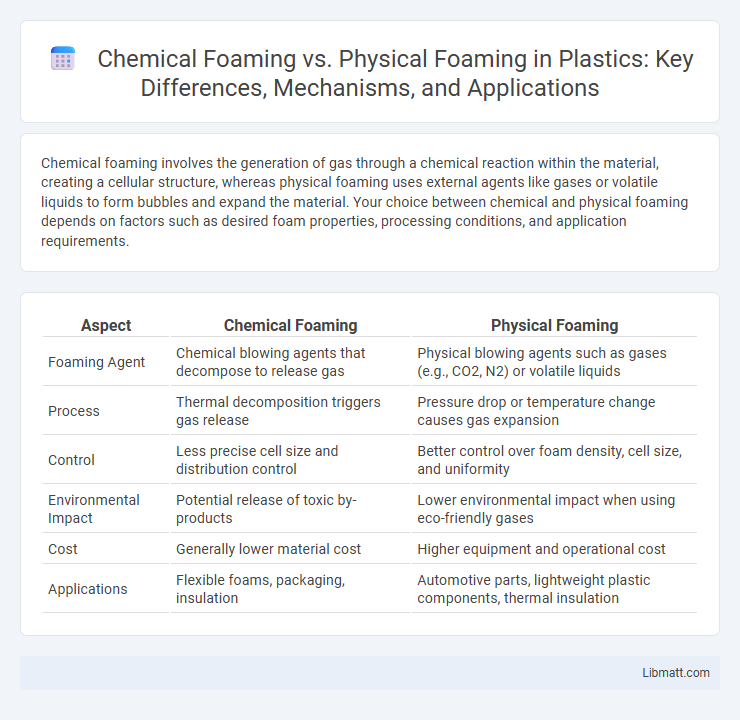

Chemical foaming involves the generation of gas through a chemical reaction within the material, creating a cellular structure, whereas physical foaming uses external agents like gases or volatile liquids to form bubbles and expand the material. Your choice between chemical and physical foaming depends on factors such as desired foam properties, processing conditions, and application requirements.

Table of Comparison

| Aspect | Chemical Foaming | Physical Foaming |

|---|---|---|

| Foaming Agent | Chemical blowing agents that decompose to release gas | Physical blowing agents such as gases (e.g., CO2, N2) or volatile liquids |

| Process | Thermal decomposition triggers gas release | Pressure drop or temperature change causes gas expansion |

| Control | Less precise cell size and distribution control | Better control over foam density, cell size, and uniformity |

| Environmental Impact | Potential release of toxic by-products | Lower environmental impact when using eco-friendly gases |

| Cost | Generally lower material cost | Higher equipment and operational cost |

| Applications | Flexible foams, packaging, insulation | Automotive parts, lightweight plastic components, thermal insulation |

Introduction to Foaming Processes

Chemical foaming involves the generation of gas through a chemical reaction within the polymer matrix, typically using blowing agents that decompose at specific temperatures to release gases like carbon dioxide or nitrogen. Physical foaming relies on the expansion of pre-formed gas bubbles, often using inert gases such as nitrogen or carbon dioxide injected under high pressure, causing cell nucleation and growth when pressure is released. Both processes are crucial in producing lightweight, porous polymer materials with distinct cellular structures tailored for applications in insulation, packaging, and automotive industries.

What is Chemical Foaming?

Chemical foaming involves the generation of gas through a chemical reaction within a polymer matrix, typically initiated by heat or pressure, producing microcellular structures during the manufacturing process. This method employs chemical blowing agents, such as azodicarbonamide, which decompose to release gases like nitrogen or carbon dioxide, leading to foam formation. Chemical foaming is widely used in plastics, rubber, and insulation industries for creating lightweight, insulating, and cushioning materials.

What is Physical Foaming?

Physical foaming is a process in polymer manufacturing where gas or a physical blowing agent is introduced into the material, causing cell formation and expansion without chemical reactions. Common physical blowing agents include nitrogen, carbon dioxide, and volatile liquids that vaporize under heat or pressure changes, creating a foamed structure. This method offers precise control over cell size and density, making it ideal for producing lightweight, insulating materials with consistent properties.

Key Differences Between Chemical and Physical Foaming

Chemical foaming involves the generation of gas through a chemical reaction within a polymer matrix, producing foam with uniform cell structure and lower density, while physical foaming relies on the expansion of gases like CO2 or nitrogen introduced externally under pressure. Chemical foaming agents decompose upon heating, releasing gases such as nitrogen or carbon dioxide that create the foam, whereas physical foaming uses physical blowing agents that vaporize to form cells without altering the chemical composition. Your choice between chemical and physical foaming impacts factors like cell size, processing complexity, environmental considerations, and application-specific mechanical properties.

Comparative Advantages of Chemical Foaming

Chemical foaming offers precise control over foam density and cell structure, resulting in consistent material performance. The process allows for flexibility in formulation, enabling customization for specific applications such as insulation, packaging, and automotive parts. You benefit from improved mechanical properties and cost efficiency compared to physical foaming methods.

Comparative Advantages of Physical Foaming

Physical foaming offers precise control over pore size and distribution, resulting in consistent material properties and enhanced mechanical strength. It eliminates the need for chemical blowing agents, reducing potential environmental and health hazards during production. The process allows scalability and adaptability to various polymers, making it ideal for industries requiring lightweight and durable foam products.

Applications of Chemical Foaming

Chemical foaming is widely used in applications such as plastic manufacturing, where it creates lightweight and insulating foam materials for packaging, construction, and automotive parts. This process introduces chemical blowing agents that decompose to generate gas, forming a cellular structure within polymers to enhance thermal insulation and reduce material density. Your choice of chemical foaming can improve product durability and cost-efficiency in industries requiring precise foam density control.

Applications of Physical Foaming

Physical foaming is widely utilized in industries such as packaging, automotive, and construction due to its ability to produce lightweight, durable, and thermally insulating materials. Applications include the manufacturing of expanded polystyrene (EPS) for protective packaging, polyethylene foam for automotive parts, and extruded polystyrene (XPS) panels used in building insulation. This method is preferred for its environmental benefits, as it often relies on physical blowing agents like CO2 or nitrogen, reducing the use of harmful chemical additives.

Environmental Impact: Chemical vs Physical Foaming

Chemical foaming typically releases volatile organic compounds (VOCs) and other byproducts that can contribute to air pollution and environmental toxicity. Physical foaming relies on inert gases like nitrogen or carbon dioxide, minimizing harmful emissions and reducing the carbon footprint. Choosing physical foaming can better align with your sustainability goals by lowering environmental impact during manufacturing.

Choosing the Right Foaming Method

Choosing the right foaming method depends on the application requirements, material compatibility, and desired foam properties such as cell size and density. Chemical foaming involves the decomposition of chemical blowing agents at elevated temperatures, creating gas that expands the polymer matrix, ideal for uniform and fine-cell foam structures. Physical foaming uses external gases like CO2 or nitrogen, offering precise control over foam morphology and lower environmental impact, making it suitable for applications demanding high-performance and environmentally friendly materials.

Chemical Foaming vs Physical Foaming Infographic

libmatt.com

libmatt.com