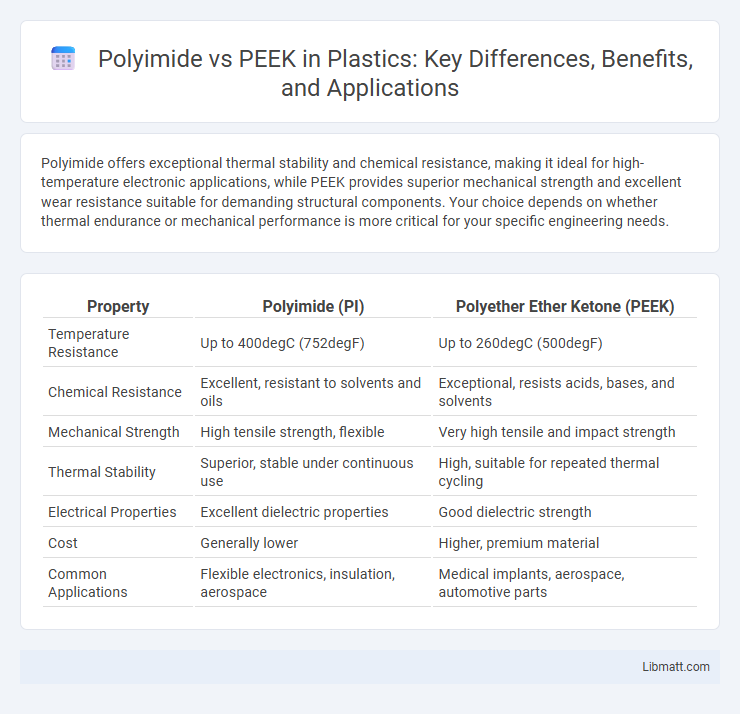

Polyimide offers exceptional thermal stability and chemical resistance, making it ideal for high-temperature electronic applications, while PEEK provides superior mechanical strength and excellent wear resistance suitable for demanding structural components. Your choice depends on whether thermal endurance or mechanical performance is more critical for your specific engineering needs.

Table of Comparison

| Property | Polyimide (PI) | Polyether Ether Ketone (PEEK) |

|---|---|---|

| Temperature Resistance | Up to 400degC (752degF) | Up to 260degC (500degF) |

| Chemical Resistance | Excellent, resistant to solvents and oils | Exceptional, resists acids, bases, and solvents |

| Mechanical Strength | High tensile strength, flexible | Very high tensile and impact strength |

| Thermal Stability | Superior, stable under continuous use | High, suitable for repeated thermal cycling |

| Electrical Properties | Excellent dielectric properties | Good dielectric strength |

| Cost | Generally lower | Higher, premium material |

| Common Applications | Flexible electronics, insulation, aerospace | Medical implants, aerospace, automotive parts |

Introduction to Polyimide and PEEK

Polyimide and PEEK (Polyether ether ketone) are high-performance polymers known for their exceptional thermal stability and mechanical strength in advanced engineering applications. Polyimide exhibits superior heat resistance up to 400degC and excellent electrical insulation properties, making it ideal for electronics and aerospace industries. PEEK offers outstanding chemical resistance and mechanical durability at continuous use temperatures around 250degC, commonly utilized in automotive, medical, and industrial sectors.

Chemical Structure Comparison

Polyimide features a rigid aromatic backbone with imide linkages that provide exceptional thermal stability and chemical resistance, while PEEK consists of a semi-crystalline thermoplastic structure with ketone and ether groups contributing to its toughness and resistance to hydrocarbons. The aromatic rings and imide bonds in polyimide create a highly stable polymer chain, enhancing its performance in extreme environments. In contrast, PEEK's alternating aryl carbonyl and ether linkages balance mechanical strength and chemical inertness, making it suitable for demanding engineering applications.

Mechanical Properties Analysis

Polyimide exhibits excellent mechanical strength and flexibility, making it suitable for high-temperature applications with sustained stress, while PEEK offers superior tensile strength and impact resistance ideal for demanding structural uses. Both polymers resist wear and fatigue, but PEEK's higher modulus of elasticity provides enhanced stiffness compared to polyimide. Understanding these mechanical properties helps you select the optimal material for applications requiring durability and thermal stability.

Thermal Stability and Performance

Polyimide demonstrates superior thermal stability with continuous use temperatures up to 400degC, making it ideal for extreme heat applications. PEEK offers excellent thermal performance as well, with a maximum continuous service temperature around 260degC, providing strong mechanical properties under high heat. Your choice between polyimide and PEEK should consider the specific thermal endurance needed for your application's operating environment.

Electrical Insulation Capabilities

Polyimide offers excellent electrical insulation capabilities with a high dielectric strength, making it suitable for high-frequency and high-temperature applications. PEEK also provides strong electrical insulation but typically exhibits slightly lower dielectric strength compared to polyimide, while excelling in mechanical and chemical resistance. Your choice between polyimide and PEEK should consider the specific voltage, frequency, and thermal conditions of your electrical application.

Chemical Resistance Differences

Polyimide exhibits exceptional chemical resistance to solvents, oils, and acids, maintaining structural integrity in harsh chemical environments. PEEK offers superior resistance to a broader spectrum of chemicals, including strong acids, bases, and hydrocarbon solvents, making it ideal for highly aggressive industrial applications. Understanding these chemical resistance differences helps you select the optimal polymer for your specific corrosion and chemical exposure challenges.

Wear and Friction Characteristics

Polyimide exhibits excellent wear resistance and low friction coefficients, making it ideal for high-performance applications requiring durability under continuous sliding or abrasive contact. PEEK also offers superior wear properties with outstanding self-lubricating characteristics that reduce friction and extend component life in demanding mechanical environments. Your choice between Polyimide and PEEK should consider specific operational conditions, as Polyimide performs well under moderate temperatures while PEEK maintains stability and low friction in harsher, high-temperature settings.

Biocompatibility and Medical Applications

Polyimide and PEEK both exhibit excellent biocompatibility, making them suitable for various medical applications such as implants and surgical instruments. PEEK is favored for long-term implantable devices due to its superior chemical resistance and mechanical strength, while polyimide is widely used in flexible electronics and catheters because of its thermal stability and flexibility. Your choice depends on specific medical needs, balancing durability with the material's interaction within the human body.

Cost and Manufacturing Considerations

Polyimide typically offers lower raw material costs and easier processing via conventional methods compared to PEEK, which requires higher processing temperatures and specialized equipment, increasing manufacturing expenses. Your choice impacts production budgets significantly as PEEK's enhanced mechanical properties and chemical resistance come with higher tooling and energy requirements. Assessing cost-effectiveness involves balancing Polyimide's affordability against PEEK's performance advantages in demanding applications.

Application-Specific Recommendations

Polyimide is ideal for high-temperature aerospace and electronics applications due to its exceptional thermal stability and electrical insulation properties. PEEK excels in medical implants and industrial machinery where chemical resistance and mechanical strength at elevated temperatures are critical. Selecting between Polyimide and PEEK depends on specific performance requirements such as thermal endurance, mechanical load, and environmental exposure.

Polyimide vs PEEK Infographic

libmatt.com

libmatt.com