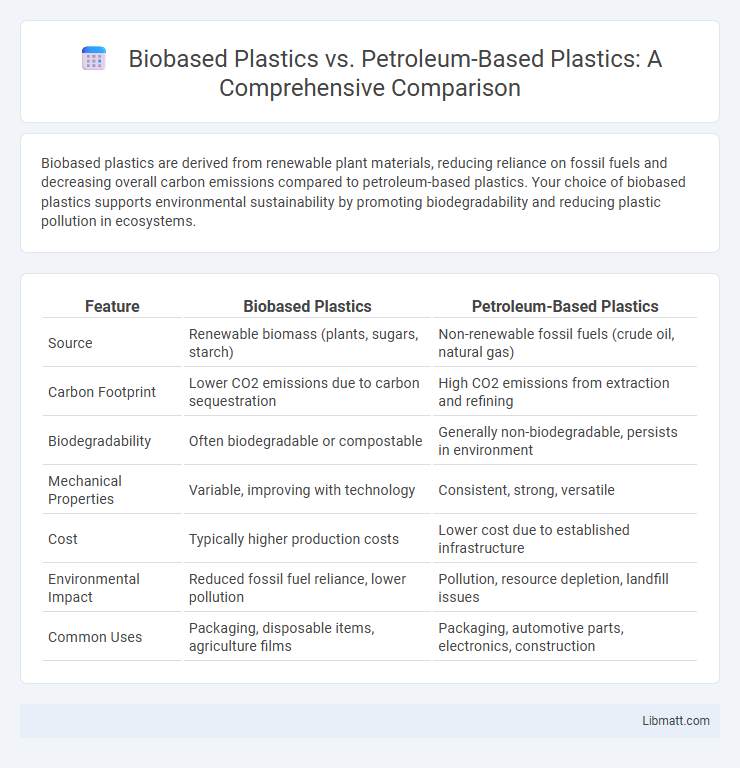

Biobased plastics are derived from renewable plant materials, reducing reliance on fossil fuels and decreasing overall carbon emissions compared to petroleum-based plastics. Your choice of biobased plastics supports environmental sustainability by promoting biodegradability and reducing plastic pollution in ecosystems.

Table of Comparison

| Feature | Biobased Plastics | Petroleum-Based Plastics |

|---|---|---|

| Source | Renewable biomass (plants, sugars, starch) | Non-renewable fossil fuels (crude oil, natural gas) |

| Carbon Footprint | Lower CO2 emissions due to carbon sequestration | High CO2 emissions from extraction and refining |

| Biodegradability | Often biodegradable or compostable | Generally non-biodegradable, persists in environment |

| Mechanical Properties | Variable, improving with technology | Consistent, strong, versatile |

| Cost | Typically higher production costs | Lower cost due to established infrastructure |

| Environmental Impact | Reduced fossil fuel reliance, lower pollution | Pollution, resource depletion, landfill issues |

| Common Uses | Packaging, disposable items, agriculture films | Packaging, automotive parts, electronics, construction |

Introduction to Biobased and Petroleum-Based Plastics

Biobased plastics are derived from renewable biological sources such as corn, sugarcane, or cellulose, offering an eco-friendly alternative to traditional petroleum-based plastics made from fossil fuels. These materials often reduce greenhouse gas emissions and reliance on non-renewable resources, supporting sustainable production cycles. Understanding the key differences between your options can guide environmentally conscious decisions in packaging, manufacturing, and product design.

Chemical Composition and Raw Materials

Biobased plastics are derived from renewable biomass sources such as corn starch, sugarcane, and cellulose, which consist primarily of carbohydrates like glucose and fructose that are polymerized into materials like polylactic acid (PLA) and polyhydroxyalkanoates (PHA). Petroleum-based plastics originate from fossil fuels, mainly crude oil and natural gas, composed of hydrocarbon chains that are polymerized into widely used plastics like polyethylene (PE), polypropylene (PP), and polystyrene (PS). The chemical composition of biobased plastics typically includes oxygen-rich functional groups, whereas petroleum-based plastics are primarily hydrocarbon polymers lacking oxygen atoms, influencing their biodegradability and environmental impact.

Production Processes Compared

Biobased plastics are produced through the fermentation of renewable biomass such as corn starch, sugarcane, or cellulose, converting organic materials into polymers like polylactic acid (PLA). Petroleum-based plastics are synthesized from hydrocarbon monomers derived from crude oil refining through polymerization processes such as cracking and polymer chain growth. Production of biobased plastics generally results in lower greenhouse gas emissions and reduces dependency on fossil fuels compared to the energy-intensive extraction and refining necessary for petroleum-based plastics.

Environmental Impact and Carbon Footprint

Biobased plastics significantly reduce environmental impact by sourcing raw materials from renewable resources like corn or sugarcane, leading to lower greenhouse gas emissions compared to petroleum-based plastics derived from fossil fuels. Their carbon footprint is generally smaller, as biobased plastics can sequester carbon dioxide during plant growth, helping mitigate climate change effects. Understanding these differences enables you to make eco-friendly choices that contribute to reducing global plastic pollution and carbon emissions.

Biodegradability and End-of-Life Options

Biobased plastics, derived from renewable sources like corn or sugarcane, often exhibit improved biodegradability compared to petroleum-based plastics, breaking down more efficiently under composting conditions. Petroleum-based plastics typically persist in the environment for decades due to their complex polymer structures, leading to accumulation in landfills and oceans. End-of-life options for biobased plastics include industrial composting and anaerobic digestion, while petroleum-based alternatives primarily rely on mechanical recycling or landfill disposal, highlighting the environmental benefits of biobased materials.

Performance and Functional Properties

Biobased plastics often match or exceed the performance and functional properties of petroleum-based plastics in applications such as packaging, automotive parts, and consumer goods, offering comparable strength, flexibility, and durability. While petroleum-based plastics typically provide superior barrier properties and heat resistance, innovations in biobased polymer composites and additives are closing these gaps, enhancing usability in high-performance contexts. Your choice between biobased and petroleum-based plastics can balance environmental benefits with performance requirements depending on specific application needs.

Market Trends and Industry Adoption

Biobased plastics are rapidly gaining market share due to increasing consumer demand for sustainable materials and stringent environmental regulations limiting petroleum-based plastic usage. Major industries such as packaging, automotive, and electronics are progressively adopting biobased plastics to reduce carbon footprints and enhance brand sustainability credentials. Your business can benefit from these market trends by integrating biobased plastics into product lines, aligning with evolving industry standards and regulatory requirements.

Economic Considerations and Cost Analysis

Biobased plastics often incur higher production costs than petroleum-based plastics due to raw material variability and limited large-scale manufacturing infrastructure. Petroleum-based plastics benefit from established supply chains and economies of scale, making them generally more cost-effective in current markets. However, increasing environmental regulations and volatile fossil fuel prices are gradually narrowing the cost gap, improving the economic feasibility of biobased alternatives over time.

Regulatory Landscape and Certification Standards

Biobased plastics are increasingly subject to evolving regulatory frameworks such as the EU's Renewable Energy Directive and the US Federal Trade Commission's Green Guides, which emphasize accurate biobased content claims and environmental impact transparency. Certification standards like ASTM D6866 and the Biodegradable Products Institute (BPI) certification validate biobased content and compostability, ensuring compliance with international market requirements. Petroleum-based plastics face stringent restrictions, including bans on single-use items and mandates for recycling targets under regulations like the EU's Circular Economy Action Plan, highlighting a shift towards sustainable materials governance.

Future Prospects and Innovations in Plastics

Biobased plastics offer promising future prospects with advancements in biodegradable materials and sustainable production methods, reducing reliance on finite petroleum resources. Innovations such as bio-engineered polymers and enhanced recycling technologies aim to improve durability and environmental impact compared to traditional petroleum-based plastics. Your opportunities to choose biobased plastics contribute to a circular economy and support ongoing efforts toward eco-friendly plastic solutions.

Biobased Plastics vs Petroleum-Based Plastics Infographic

libmatt.com

libmatt.com