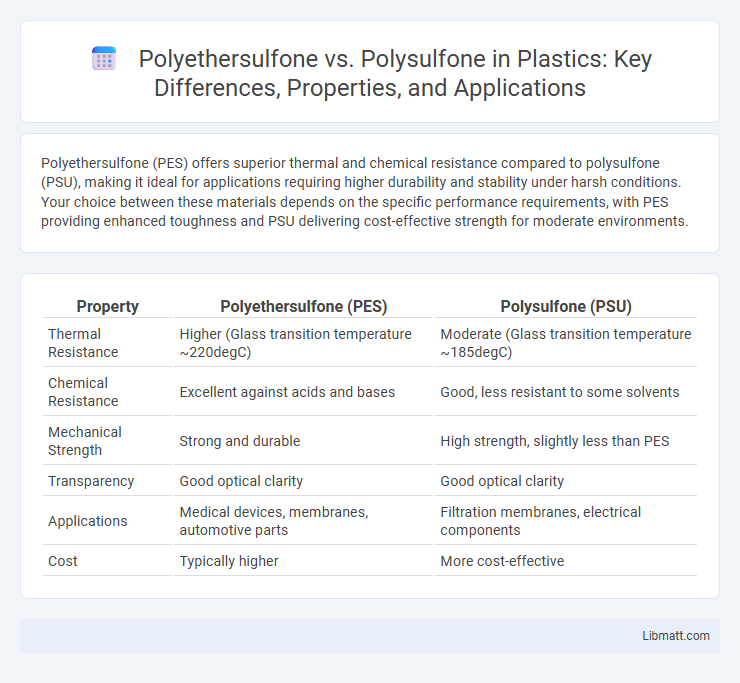

Polyethersulfone (PES) offers superior thermal and chemical resistance compared to polysulfone (PSU), making it ideal for applications requiring higher durability and stability under harsh conditions. Your choice between these materials depends on the specific performance requirements, with PES providing enhanced toughness and PSU delivering cost-effective strength for moderate environments.

Table of Comparison

| Property | Polyethersulfone (PES) | Polysulfone (PSU) |

|---|---|---|

| Thermal Resistance | Higher (Glass transition temperature ~220degC) | Moderate (Glass transition temperature ~185degC) |

| Chemical Resistance | Excellent against acids and bases | Good, less resistant to some solvents |

| Mechanical Strength | Strong and durable | High strength, slightly less than PES |

| Transparency | Good optical clarity | Good optical clarity |

| Applications | Medical devices, membranes, automotive parts | Filtration membranes, electrical components |

| Cost | Typically higher | More cost-effective |

Introduction to Polyethersulfone and Polysulfone

Polyethersulfone (PES) and Polysulfone (PSU) are high-performance thermoplastic polymers known for their excellent thermal stability, chemical resistance, and mechanical strength. PES contains ether linkages that provide enhanced toughness and hydrolytic stability compared to PSU, which primarily consists of sulfone linkages offering rigidity and high-temperature resistance. Understanding the distinct molecular structures of PES and PSU helps you select the right material for applications requiring durability and performance under demanding conditions.

Chemical Structure Comparison

Polyethersulfone (PES) contains repeating units with ether (-O-) linkages along with sulfone (-SO2-) groups, providing enhanced flexibility and hydrolytic stability. Polysulfone (PSU) consists primarily of aromatic rings connected by sulfone groups without ether linkages, resulting in higher thermal stability but less chemical resistance to hydrolysis. The presence of ether linkages in PES modifies the polymer backbone, influencing solubility, mechanical properties, and resistance to oxidative degradation compared to the strictly sulfone-linked structure of PSU.

Physical Properties Overview

Polyethersulfone (PES) exhibits higher thermal stability with a glass transition temperature around 220degC compared to polysulfone's (PSU) approximately 185degC, making PES more suitable for high-temperature applications. PES typically has better chemical resistance and mechanical strength, providing enhanced durability in aggressive environments. Both materials offer excellent dimensional stability and are used in medical, automotive, and aerospace industries, but PES outperforms PSU in toughness and hydrolytic resistance.

Thermal Stability and Heat Resistance

Polyethersulfone (PES) exhibits higher thermal stability and heat resistance compared to Polysulfone (PSU), maintaining structural integrity at continuous use temperatures up to 190degC versus PSU's typical limit of around 160degC. PES demonstrates superior resistance to thermal degradation and retains mechanical properties after prolonged exposure to elevated temperatures, making it ideal for high-performance applications. The higher glass transition temperature (Tg) of PES, approximately 220degC, outperforms PSU's Tg near 185degC, confirming its enhanced thermal durability.

Mechanical Performance Differences

Polyethersulfone (PES) exhibits higher toughness and better impact resistance compared to Polysulfone (PSU), making it suitable for applications requiring enhanced mechanical durability. Both materials offer high tensile strength and rigidity, but PES outperforms PSU in flexural strength and elongation at break. These differences arise from PES's ether linkages, which provide greater molecular flexibility and resistance to mechanical stress.

Chemical Resistance and Compatibility

Polyethersulfone (PES) exhibits superior chemical resistance compared to Polysulfone (PSU), particularly against hydrolytic and oxidative degradation, making it ideal for applications involving aggressive chemicals and high-temperature sterilization. Polysulfone offers good resistance to acids, bases, and hot water but can be less stable in the presence of strong oxidizing agents. Understanding these differences helps you select the right polymer for your chemical compatibility and durability requirements.

Processability and Manufacturing Methods

Polyethersulfone (PES) offers superior processability compared to Polysulfone (PSU) due to its higher thermal stability and better chemical resistance, enabling easier molding and extrusion at elevated temperatures. Manufacturing methods for PES often include injection molding, extrusion, and blow molding, leveraging its excellent melt strength and flow properties. Polysulfone typically requires lower processing temperatures and is commonly shaped using injection molding and thermoforming, but its narrower processing window limits manufacturing flexibility relative to PES.

Common Industrial Applications

Polyethersulfone (PES) finds common industrial applications in medical devices, food processing equipment, and filtration membranes due to its excellent hydrolytic stability and biocompatibility. Polysulfone (PSU) is widely used in automotive parts, electrical connectors, and aerospace components because of its high thermal stability and mechanical strength. Both polymers are integral in industries requiring materials that withstand harsh chemicals and high temperatures.

Cost and Market Availability

Polyethersulfone (PES) typically costs more than Polysulfone (PSU) due to its superior thermal stability and chemical resistance, which justify its premium pricing in specialized applications. Both materials are widely available in the market, but Polysulfone enjoys broader distribution and higher volume production, making it more accessible and cost-effective for general use. Your selection between the two should weigh the budget constraints against the performance benefits provided by PES.

Choosing Between Polyethersulfone and Polysulfone

Polyethersulfone (PES) offers superior chemical resistance and higher thermal stability compared to Polysulfone (PSU), making PES ideal for applications requiring prolonged exposure to aggressive chemicals and sterilization processes. Polysulfone provides excellent mechanical strength and dimensional stability at a lower cost, which suits applications involving moderate temperature and chemical exposure. Selecting between PES and PSU depends on balancing the need for enhanced durability and chemical resistance against budget and performance requirements in specific industrial or medical applications.

Polyethersulfone vs Polysulfone Infographic

libmatt.com

libmatt.com