Polyphthalamide (PPA) offers superior thermal resistance, chemical stability, and mechanical strength compared to standard polyamide (PA), making it ideal for high-performance engineering applications. Your choice between polyphthalamide and polyamide depends on the required durability and environmental conditions of the final product.

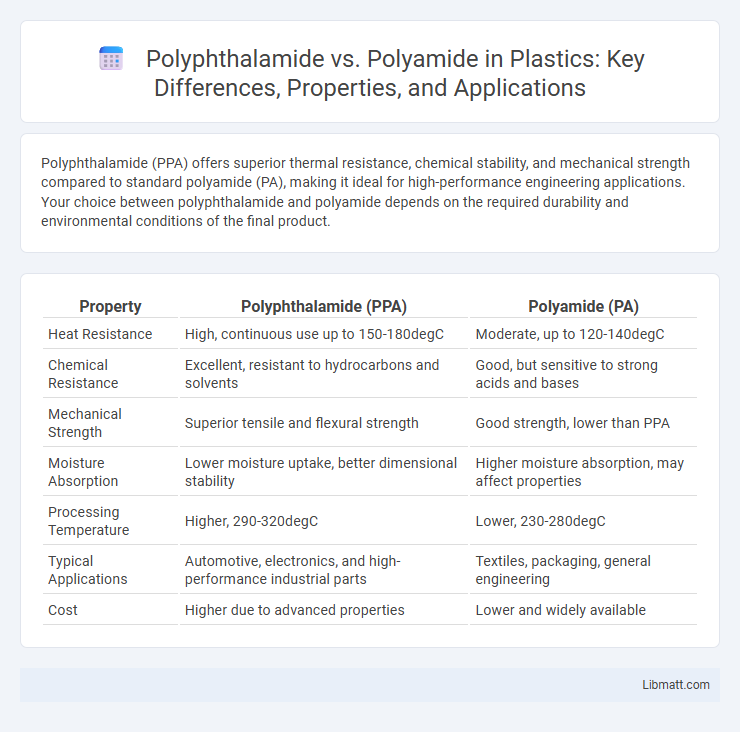

Table of Comparison

| Property | Polyphthalamide (PPA) | Polyamide (PA) |

|---|---|---|

| Heat Resistance | High, continuous use up to 150-180degC | Moderate, up to 120-140degC |

| Chemical Resistance | Excellent, resistant to hydrocarbons and solvents | Good, but sensitive to strong acids and bases |

| Mechanical Strength | Superior tensile and flexural strength | Good strength, lower than PPA |

| Moisture Absorption | Lower moisture uptake, better dimensional stability | Higher moisture absorption, may affect properties |

| Processing Temperature | Higher, 290-320degC | Lower, 230-280degC |

| Typical Applications | Automotive, electronics, and high-performance industrial parts | Textiles, packaging, general engineering |

| Cost | Higher due to advanced properties | Lower and widely available |

Introduction to Polyphthalamide and Polyamide

Polyphthalamide (PPA) is a high-performance thermoplastic polymer known for its enhanced thermal stability, chemical resistance, and mechanical strength compared to conventional polyamide (PA). Polyamide, commonly referred to as nylon, is a widely used engineering plastic recognized for its toughness, abrasion resistance, and versatility in automotive, textile, and industrial applications. The molecular structure of polyphthalamide incorporates aromatic rings, which contribute to its superior thermal and chemical properties, distinguishing it from aliphatic polyamides.

Chemical Structure Comparison

Polyphthalamide (PPA) features a chemical structure with aromatic rings and imide linkages, providing enhanced thermal and chemical resistance compared to traditional polyamide (PA) which consists mainly of aliphatic chains and amide bonds. The presence of rigid aromatic segments in PPA's polymer backbone results in higher melting points and improved dimensional stability under stress. Your choice between these polymers should consider the specific chemical environment and mechanical requirements, as PPA offers superior performance in harsh conditions versus standard polyamide materials.

Mechanical Properties

Polyphthalamide (PPA) exhibits superior mechanical properties compared to traditional polyamide (PA), including higher tensile strength and enhanced stiffness, making it ideal for demanding engineering applications. PPA's elevated heat resistance contributes to maintaining mechanical integrity under high-temperature conditions where PA typically softens or degrades. Improved dimensional stability and wear resistance in PPA further ensure prolonged performance in automotive and electrical components compared to standard polyamides.

Thermal Resistance

Polyphthalamide (PPA) exhibits significantly higher thermal resistance compared to traditional polyamide (PA), with continuous use temperatures often exceeding 150degC and short-term resistance up to 250degC. This enhanced thermal stability allows PPA to maintain mechanical properties and dimensional stability in extreme heat environments. As a result, PPA is preferred for automotive and industrial applications where high-temperature performance is critical.

Moisture Absorption Differences

Polyphthalamide (PPA) exhibits significantly lower moisture absorption compared to conventional polyamide (PA), typically absorbing less than 1% water by weight, which enhances its dimensional stability and mechanical properties in humid environments. In contrast, standard polyamides like PA6 or PA66 can absorb 8-10% moisture, leading to swelling and reduced stiffness. This moisture resistance makes PPA ideal for high-performance applications requiring consistent structural integrity and reduced environmental sensitivity.

Processing Methods

Polyphthalamide (PPA) and Polyamide (PA) differ significantly in processing methods due to their thermal properties and chemical structure. PPA offers higher melting points and thermal stability, making it suitable for injection molding and extrusion processes requiring elevated temperatures, whereas conventional polyamides like PA6 and PA66 typically process at lower temperatures. Processing equipment for PPA must accommodate its viscosity and moisture sensitivity, often necessitating specialized drying and precision temperature control to ensure optimal mechanical performance and dimensional stability.

Applications in Industry

Polyphthalamide (PPA) offers superior thermal stability and chemical resistance compared to standard polyamide (PA), making it ideal for automotive under-the-hood components and electrical connectors that require long-term durability. PPA's high melting point enables its use in HVAC systems and industrial machinery parts exposed to elevated temperatures, where conventional polyamides might fail. Industries such as aerospace and electronics benefit from PPA's dimensional stability and resistance to hydrolysis, enhancing performance in demanding environments.

Cost and Availability

Polyphthalamide (PPA) generally costs more than traditional polyamide (PA) due to its enhanced thermal and chemical resistance, making it ideal for high-performance applications. While polyamide is widely available and produced in large volumes globally, Polyphthalamide's availability is more limited because of fewer manufacturers and specialized production processes. Cost considerations favor polyamide for budget-sensitive projects, while PPA's higher price is justified by its superior durability and performance in demanding environments.

Environmental Impact

Polyphthalamide (PPA) has a lower environmental impact compared to traditional polyamide (PA) due to its enhanced durability and longer lifespan, reducing the frequency of replacement and waste generation. PPA's higher thermal stability and chemical resistance lead to less material degradation and lower emissions during manufacturing and usage. Choosing PPA can help your projects achieve improved sustainability by minimizing resource consumption and environmental footprint.

Conclusion and Material Selection Guide

Polyphthalamide (PPA) offers superior thermal stability, chemical resistance, and mechanical strength compared to traditional polyamide (PA), making it ideal for high-performance applications demanding durability and heat resistance. Your material selection should prioritize PPA for automotive, electrical, and industrial components requiring long-term reliability under harsh conditions, while polyamide remains suitable for less demanding, cost-sensitive applications. Evaluating specific environmental factors and mechanical requirements ensures optimal performance and cost-efficiency when choosing between PPA and PA.

Polyphthalamide vs Polyamide Infographic

libmatt.com

libmatt.com