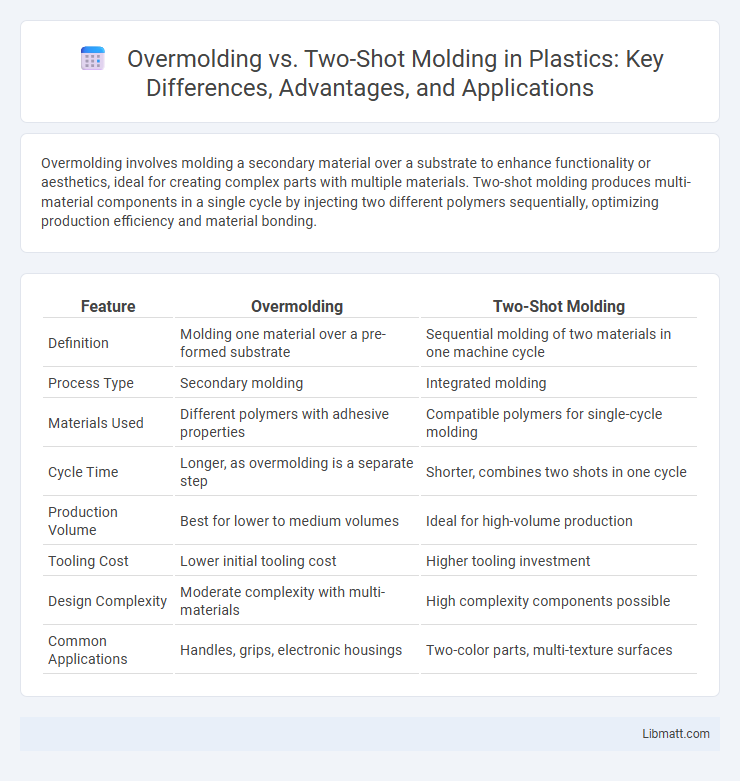

Overmolding involves molding a secondary material over a substrate to enhance functionality or aesthetics, ideal for creating complex parts with multiple materials. Two-shot molding produces multi-material components in a single cycle by injecting two different polymers sequentially, optimizing production efficiency and material bonding.

Table of Comparison

| Feature | Overmolding | Two-Shot Molding |

|---|---|---|

| Definition | Molding one material over a pre-formed substrate | Sequential molding of two materials in one machine cycle |

| Process Type | Secondary molding | Integrated molding |

| Materials Used | Different polymers with adhesive properties | Compatible polymers for single-cycle molding |

| Cycle Time | Longer, as overmolding is a separate step | Shorter, combines two shots in one cycle |

| Production Volume | Best for lower to medium volumes | Ideal for high-volume production |

| Tooling Cost | Lower initial tooling cost | Higher tooling investment |

| Design Complexity | Moderate complexity with multi-materials | High complexity components possible |

| Common Applications | Handles, grips, electronic housings | Two-color parts, multi-texture surfaces |

Introduction to Overmolding and Two-Shot Molding

Overmolding is a manufacturing process where one material is molded over another to create a single, multi-material component with enhanced functionality. Two-shot molding involves injecting two different materials sequentially into the same mold to form complex parts with distinct regions in a single cycle. Your choice between overmolding and two-shot molding depends on factors like production volume, design complexity, and material compatibility.

What is Overmolding?

Overmolding is a manufacturing process where a secondary material is molded over a primary substrate to create a single, unified part with enhanced features such as improved grip, aesthetics, or functionality. This technique is often used in industries like automotive, electronics, and medical devices to combine materials with different properties, such as soft rubber over hard plastic. Your product benefits from increased durability and design flexibility without the need for assembly, making it a cost-effective solution for complex multi-material components.

What is Two-Shot Molding?

Two-shot molding, also known as multi-shot molding, is an advanced injection molding process that involves injecting two different materials or colors into a single mold in sequential steps, creating a unified part with distinct material characteristics. This technique enhances product functionality, improves aesthetics, and reduces assembly costs by producing complex components like buttons, grips, or seals with varying textures or hardness. Your manufacturing efficiency benefits from improved durability and precision compared to traditional overmolding, where a secondary material is molded onto a pre-formed substrate.

Key Differences Between Overmolding and Two-Shot Molding

Overmolding involves molding one material over a pre-existing part, creating a layered construction, while two-shot molding integrates two materials in a single molding cycle using a dual-barrel injection system. Overmolding offers flexibility by allowing different materials and colors to be combined post initial molding, whereas two-shot molding produces a seamless bond with precise control and higher cycle efficiency. Your choice depends on factors like production volume, design complexity, and material compatibility for optimal manufacturing outcomes.

Material Selection in Overmolding vs Two-Shot Molding

Material selection in overmolding requires compatibility between the substrate and the overmold materials to ensure proper bonding, often combining rigid plastics with softer elastomers for enhanced functionality. Two-shot molding involves sequential injection of two different materials within the same mold cycle, demanding precise material pairing that balances flow properties and adhesion for seamless integration. Your choice depends on the specific performance requirements and production efficiency goals, as each method offers distinct advantages in material versatility and bonding strength.

Process Steps Comparison

Overmolding involves a two-step process where a base part is molded first, then placed into a second mold to add a different material layer, enhancing functionality and aesthetics. Two-shot molding combines these steps into a single automated cycle with two injection units, injecting different polymers consecutively without removing the part, improving production speed and precision. Understanding these process steps helps you select the ideal technique for your manufacturing needs based on complexity and volume.

Design Flexibility and Complexity

Overmolding offers greater design flexibility by enabling multiple materials and colors to be combined in a single part, allowing for complex shapes and enhanced ergonomics. Two-shot molding excels in precision and repeatability for complex designs with tightly integrated multi-material components, often resulting in improved aesthetic and functional quality. Your choice depends on the specific complexity and customization requirements of the product design.

Cost Considerations: Overmolding vs Two-Shot Molding

Overmolding generally incurs higher initial tooling costs due to the need for separate molds and multiple processing steps, making it less cost-effective for high-volume production runs. Two-shot molding reduces labor and assembly costs by sequentially injecting two materials in a single cycle, resulting in lower per-unit costs for large-scale manufacturing. Businesses must weigh upfront investment against volume requirements to determine the optimal cost strategy between overmolding and two-shot molding.

Common Applications and Industry Use Cases

Overmolding is widely used in automotive components, medical devices, and consumer electronics to enhance grip, protection, and aesthetics by combining different materials in a single part. Two-shot molding is prevalent in producing multi-colored products, buttons, and seals in industries such as automotive, household appliances, and toys, offering precise color control and integrated assemblies. Both techniques improve product functionality and reduce assembly time, with overmolding excelling in mechanical bonding and two-shot molding optimizing visual design and complex geometries.

Choosing the Right Molding Technique for Your Project

Choosing between overmolding and two-shot molding depends on your project's complexity and production volume requirements. Overmolding offers flexibility by allowing different materials to be combined in separate molding steps, ideal for prototypes or low-volume runs, while two-shot molding integrates multiple materials in a single automated process, enhancing efficiency for high-volume manufacturing. Evaluating factors such as material compatibility, design intricacies, and cost-effectiveness will help determine the best molding technique for your application.

Overmolding vs two-shot molding Infographic

libmatt.com

libmatt.com