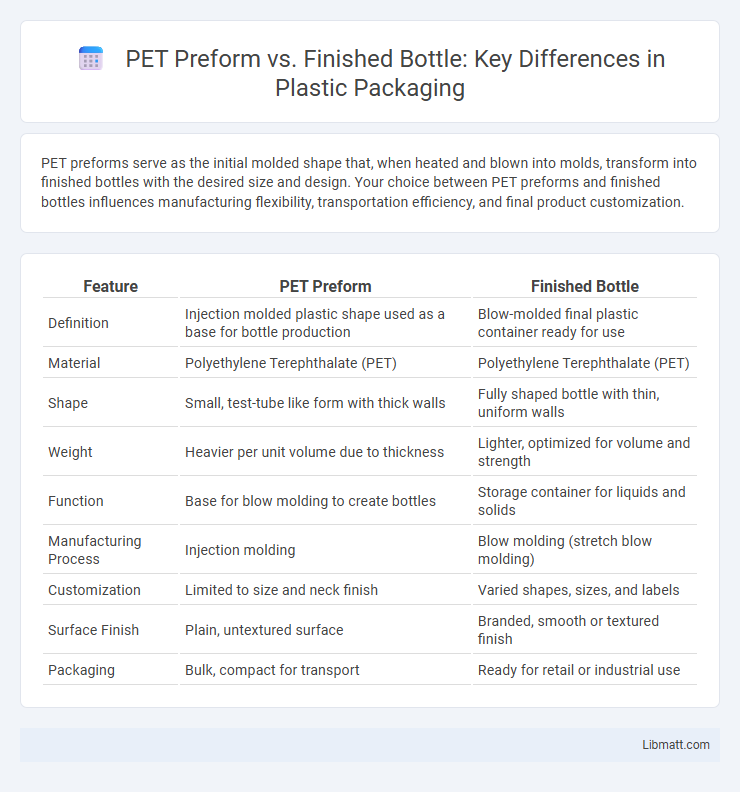

PET preforms serve as the initial molded shape that, when heated and blown into molds, transform into finished bottles with the desired size and design. Your choice between PET preforms and finished bottles influences manufacturing flexibility, transportation efficiency, and final product customization.

Table of Comparison

| Feature | PET Preform | Finished Bottle |

|---|---|---|

| Definition | Injection molded plastic shape used as a base for bottle production | Blow-molded final plastic container ready for use |

| Material | Polyethylene Terephthalate (PET) | Polyethylene Terephthalate (PET) |

| Shape | Small, test-tube like form with thick walls | Fully shaped bottle with thin, uniform walls |

| Weight | Heavier per unit volume due to thickness | Lighter, optimized for volume and strength |

| Function | Base for blow molding to create bottles | Storage container for liquids and solids |

| Manufacturing Process | Injection molding | Blow molding (stretch blow molding) |

| Customization | Limited to size and neck finish | Varied shapes, sizes, and labels |

| Surface Finish | Plain, untextured surface | Branded, smooth or textured finish |

| Packaging | Bulk, compact for transport | Ready for retail or industrial use |

Introduction to PET Preforms and Finished Bottles

PET preforms are the initial molded forms made from polyethylene terephthalate resin, designed to be heated and blown into finished bottles. Finished PET bottles result from stretching and blowing these preforms into their final shapes, offering lightweight, durable packaging for beverages and other liquids. Understanding the difference between PET preforms and finished bottles is essential for optimizing your packaging process and improving production efficiency.

Overview of the PET Bottle Manufacturing Process

PET bottle manufacturing begins with the production of PET preforms through injection molding, which creates a thick, test-tube shaped intermediate product. These preforms are then reheated and blown into molds using stretch blow molding to form finished bottles with precise shapes and sizes. This process ensures uniformity, strength, and clarity in PET bottles used for beverages and other consumer goods.

What Are PET Preforms?

PET preforms are small, test-tube-shaped plastic pieces made from polyethylene terephthalate resin, serving as the intermediate stage in the production of PET bottles. These preforms undergo a heating and blow-molding process to expand into the shape of finished bottles used for packaging beverages, cosmetics, and other liquids. The quality, size, and design of PET preforms directly impact the strength, clarity, and weight of the final PET bottles.

What Is a Finished PET Bottle?

A finished PET bottle is a fully molded, shaped, and cooled container ready for use in packaging liquids such as water, beverages, and food products. It is created from a PET preform, which undergoes a blow molding process to expand into its final bottle form with specific dimensions and structural features. These bottles offer durability, transparency, and lightweight properties, making them ideal for consumer packaging.

Key Differences Between PET Preforms and Finished Bottles

PET preforms are the intermediate molded plastic pieces shaped like test tubes, which serve as the raw material for producing finished PET bottles through a blow molding process. Finished PET bottles offer full functionality with their final shape, size, and design, incorporating features like neck finishes, threading, and structural integrity for packaging liquids. Understanding the transformation from preform to bottle highlights the efficiency and customization potential in your manufacturing workflow.

Advantages of Using PET Preforms

PET preforms offer superior quality control and consistency, ensuring uniform wall thickness and clarity in the final product. Their compact size significantly reduces storage and transportation costs compared to finished bottles. Using PET preforms allows manufacturers to customize bottle shapes and sizes during the blow molding process, increasing design flexibility and production efficiency.

Benefits of Finished PET Bottles

Finished PET bottles offer enhanced structural integrity and superior barrier properties compared to PET preforms, ensuring optimal product preservation and shelf life. Their ready-to-use form reduces manufacturing time and operational costs, streamlining your packaging process. Finished bottles also provide versatile design options for branding and consumer appeal, making them ideal for a wide range of beverages and products.

Applications of PET Preforms and Finished Bottles

PET preforms serve as the foundational intermediate product used primarily in the manufacturing of finished bottles for packaging beverages, pharmaceuticals, and personal care products. Finished PET bottles are widely applied across the food and beverage industry due to their lightweight, durability, and excellent barrier properties that maintain product freshness and safety. Industries such as cosmetics, household chemicals, and healthcare utilize finished PET bottles for their versatility in shaping, labeling, and customization to meet diverse packaging requirements.

Cost and Efficiency Comparison

PET preforms offer significant cost advantages due to lower transportation and storage expenses, as they are compact and lightweight compared to finished bottles. Manufacturing efficiency improves with preforms, enabling faster cycle times in blow molding processes and reducing energy consumption per unit produced. Finished bottles, while ready for immediate use, involve higher shipping costs and greater warehousing needs, which can decrease overall cost efficiency in large-scale production.

Choosing Between PET Preforms and Finished Bottles

Choosing between PET preforms and finished bottles depends on factors such as production flexibility, cost-efficiency, and supply chain logistics. PET preforms allow for on-site blow molding customization, reducing storage space and enabling rapid response to demand fluctuations, while finished bottles offer immediate usability with reduced manufacturing equipment requirements. Businesses must assess production capacity, material handling, and delivery timelines to optimize packaging strategy effectively.

PET Preform vs Finished Bottle Infographic

libmatt.com

libmatt.com