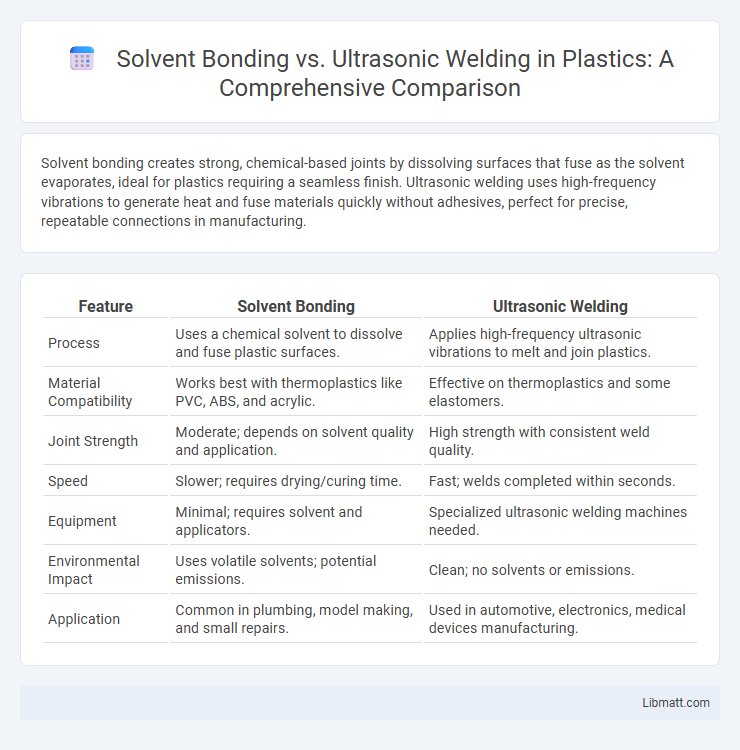

Solvent bonding creates strong, chemical-based joints by dissolving surfaces that fuse as the solvent evaporates, ideal for plastics requiring a seamless finish. Ultrasonic welding uses high-frequency vibrations to generate heat and fuse materials quickly without adhesives, perfect for precise, repeatable connections in manufacturing.

Table of Comparison

| Feature | Solvent Bonding | Ultrasonic Welding |

|---|---|---|

| Process | Uses a chemical solvent to dissolve and fuse plastic surfaces. | Applies high-frequency ultrasonic vibrations to melt and join plastics. |

| Material Compatibility | Works best with thermoplastics like PVC, ABS, and acrylic. | Effective on thermoplastics and some elastomers. |

| Joint Strength | Moderate; depends on solvent quality and application. | High strength with consistent weld quality. |

| Speed | Slower; requires drying/curing time. | Fast; welds completed within seconds. |

| Equipment | Minimal; requires solvent and applicators. | Specialized ultrasonic welding machines needed. |

| Environmental Impact | Uses volatile solvents; potential emissions. | Clean; no solvents or emissions. |

| Application | Common in plumbing, model making, and small repairs. | Used in automotive, electronics, medical devices manufacturing. |

Introduction to Solvent Bonding and Ultrasonic Welding

Solvent bonding involves using a chemical solvent to soften and fuse plastic surfaces, creating a strong, seamless joint ideal for acrylic and polycarbonate materials. Ultrasonic welding utilizes high-frequency ultrasonic vibrations to generate localized heat, melting thermoplastic components together for rapid, precise assembly without additional adhesives. Both methods efficiently join plastics but differ in application, with solvent bonding suitable for transparent materials and ultrasonic welding preferred for complex or mass production parts.

Basic Principles of Solvent Bonding

Solvent bonding relies on chemically softening the polymer surfaces by applying a solvent that temporarily dissolves the material, allowing polymer chains to interdiffuse and create a strong adhesive joint upon evaporation of the solvent. This technique is commonly used for thermoplastics such as acrylic, PVC, and polycarbonate, where the choice of solvent depends on the polymer's chemical compatibility. The resulting bond offers clear, aesthetically pleasing joints but requires controlled application to avoid material distortion or environmental hazards due to solvent fumes.

Fundamentals of Ultrasonic Welding

Ultrasonic welding uses high-frequency ultrasonic vibrations to create a solid-state weld by generating localized heat through friction between the materials' surfaces. This process enables rapid joining of thermoplastics and metals without the need for adhesives or external heat sources. The resulting bond is strong, precise, and free of contaminants, making it ideal for applications requiring clean and efficient assembly.

Suitable Materials for Each Technique

Solvent bonding is best suited for thermoplastics such as acrylic, polycarbonate, and PVC, which dissolve slightly at the surface to create strong chemical bonds. Ultrasonic welding is ideal for thermoplastics like polypropylene, ABS, and nylon, where high-frequency vibrations generate localized heat to fuse parts without adhesives. Each technique's compatibility depends on the polymer's chemical structure and thermal properties, impacting joint strength and production efficiency.

Equipment and Process Overview

Solvent bonding involves applying a chemical solvent to plastic surfaces, softening them before pressing together for a strong, seamless joint, requiring minimal and affordable equipment such as applicators and clamps. Ultrasonic welding utilizes high-frequency ultrasonic vibrations to create frictional heat, melting the materials at the interface instantly, necessitating specialized ultrasonic generators, transducers, and welding horns. Your choice depends on the materials involved and production scale, as ultrasonic welding suits rapid automation while solvent bonding offers simplicity for smaller or less complex assemblies.

Strength and Durability Comparison

Solvent bonding creates a strong chemical weld by dissolving and fusing plastic surfaces, resulting in joints that offer excellent resistance to stress and environmental factors. Ultrasonic welding generates heat through high-frequency vibrations to melt and join materials, producing bonds with superior fatigue resistance and consistent strength in precision applications. While solvent bonding excels in chemical compatibility and flexibility, ultrasonic welding provides faster cycle times and higher durability under repetitive mechanical loads.

Speed and Production Efficiency

Ultrasonic welding offers faster cycle times, typically completing joints in less than a second, significantly boosting production efficiency for high-volume manufacturing. Solvent bonding requires longer curing times, ranging from minutes to hours, which can slow down assembly lines and reduce throughput. Comparing both methods, ultrasonic welding provides superior speed and is ideal for rapid, automated processes, while solvent bonding suits applications where joint strength and chemical resistance are prioritized despite slower production rates.

Cost Considerations

Solvent bonding generally incurs lower upfront equipment costs but may involve higher expenses related to solvent handling, ventilation, and longer curing times. Ultrasonic welding requires significant initial investment in specialized machinery but offers faster processing speeds and reduced labor costs, resulting in lower per-unit costs for high-volume production. Considering overall cost efficiency, ultrasonic welding is often more economical for large-scale manufacturing, whereas solvent bonding remains cost-effective for low to medium production runs.

Environmental and Safety Factors

Solvent bonding releases volatile organic compounds (VOCs) that can pose health risks and require adequate ventilation and protective equipment, impacting environmental safety. Ultrasonic welding produces no harmful emissions, making it a cleaner, safer option for both workers and the environment. Choosing ultrasonic welding can enhance Your manufacturing process by minimizing hazardous exposure and reducing environmental impact.

Choosing the Right Method for Your Application

Selecting between solvent bonding and ultrasonic welding depends on material compatibility and application requirements. Solvent bonding excels with plastics like PVC and ABS, providing strong, chemical-resistant joints but requiring curing time. Ultrasonic welding offers rapid, precise joining for thermoplastics without adhesives, ideal for high-volume production where speed and consistency are critical.

Solvent Bonding vs Ultrasonic Welding Infographic

libmatt.com

libmatt.com