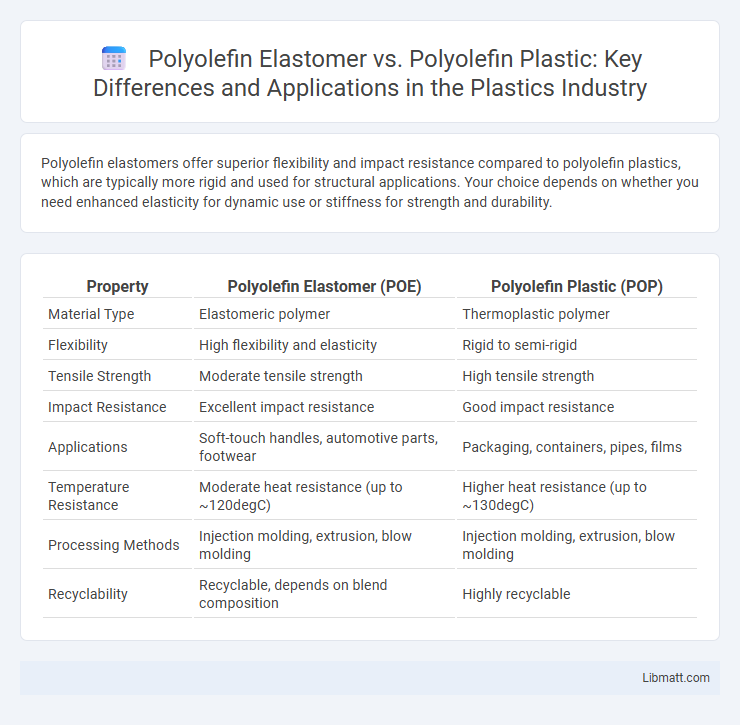

Polyolefin elastomers offer superior flexibility and impact resistance compared to polyolefin plastics, which are typically more rigid and used for structural applications. Your choice depends on whether you need enhanced elasticity for dynamic use or stiffness for strength and durability.

Table of Comparison

| Property | Polyolefin Elastomer (POE) | Polyolefin Plastic (POP) |

|---|---|---|

| Material Type | Elastomeric polymer | Thermoplastic polymer |

| Flexibility | High flexibility and elasticity | Rigid to semi-rigid |

| Tensile Strength | Moderate tensile strength | High tensile strength |

| Impact Resistance | Excellent impact resistance | Good impact resistance |

| Applications | Soft-touch handles, automotive parts, footwear | Packaging, containers, pipes, films |

| Temperature Resistance | Moderate heat resistance (up to ~120degC) | Higher heat resistance (up to ~130degC) |

| Processing Methods | Injection molding, extrusion, blow molding | Injection molding, extrusion, blow molding |

| Recyclability | Recyclable, depends on blend composition | Highly recyclable |

Introduction to Polyolefin Elastomer and Polyolefin Plastic

Polyolefin elastomers (POEs) are a class of copolymers that combine the elasticity of rubber with the durability of polyolefins, used extensively in flexible packaging, automotive parts, and footwear. Polyolefin plastics, primarily polyethylene (PE) and polypropylene (PP), are rigid thermoplastics renowned for their high chemical resistance, mechanical strength, and widespread use in containers, pipes, and household goods. The distinct molecular structures of POEs enable superior flexibility and impact resistance compared to the more crystalline and rigid nature of polyolefin plastics.

Chemical Structure Differences

Polyolefin elastomers (POEs) and polyolefin plastics differ primarily in their molecular architecture, where POEs feature a block or random copolymer structure that includes soft, rubbery segments providing elasticity. In contrast, polyolefin plastics like polyethylene and polypropylene consist of long, linear or branched polymer chains with a rigid crystalline or semi-crystalline structure, resulting in stiffness and higher melting points. Understanding these chemical structure differences helps you select the appropriate material for applications requiring flexibility or rigidity.

Manufacturing Processes Compared

Polyolefin elastomers (POEs) are produced using specialized copolymerization methods, such as metallocene catalysis, which introduce soft, flexible segments into the polymer chain, resulting in enhanced elasticity and impact resistance. Polyolefin plastics, typically made from polyethylene or polypropylene via Ziegler-Natta or metallocene catalysis, emphasize rigidity and strength, with polymerization conditions tailored for crystalline structures. Understanding these manufacturing process differences helps you select the appropriate material for applications requiring either flexibility or structural durability.

Mechanical Properties: Flexibility vs Rigidity

Polyolefin elastomers exhibit superior flexibility and elasticity, allowing them to withstand repeated stretching and bending without permanent deformation. In contrast, polyolefin plastics offer higher rigidity and structural strength, making them ideal for applications requiring durability and dimensional stability. Your choice between these materials depends on whether flexibility for dynamic use or rigidity for load-bearing purposes is the priority.

Thermal Performance and Stability

Polyolefin elastomers (POEs) exhibit superior thermal flexibility and stability, maintaining elasticity over a broader temperature range compared to polyolefin plastics, which tend to become brittle at lower temperatures. POEs can withstand repeated thermal cycling without significant degradation, enhancing durability in dynamic applications. Polyolefin plastics, such as polyethylene and polypropylene, typically offer higher melting points but have lower thermal impact resistance and are more prone to thermal deformation under stress.

Key Applications in Various Industries

Polyolefin elastomers are extensively used in automotive parts, flexible tubing, and soft-touch consumer goods due to their excellent flexibility and impact resistance. Polyolefin plastics find key applications in packaging, household containers, and construction materials because of their rigidity, chemical resistance, and cost-effectiveness. Both materials serve critical roles in industries like healthcare, electronics, and agriculture, offering tailored performance based on elasticity or structural strength requirements.

Environmental Impact and Recyclability

Polyolefin elastomers (POEs) exhibit improved flexibility compared to conventional polyolefin plastics, yet both materials share a similar environmental footprint due to their hydrocarbon base derived from non-renewable fossil fuels. POEs present challenges during recycling processes because their elastomeric nature complicates sorting and can reduce the mechanical properties of recycled polyolefins. Polyolefin plastics like polyethylene (PE) and polypropylene (PP) benefit from well-established recycling streams, enabling higher recyclability rates and lower environmental impact compared to POEs.

Cost Analysis and Economic Considerations

Polyolefin elastomers generally incur higher initial costs compared to polyolefin plastics due to their specialized manufacturing processes and enhanced elasticity properties. Economic considerations favor polyolefin plastics in large-scale applications where cost-efficiency and rigidity are prioritized, while elastomers justify their expense in flexible, durable applications such as automotive seals and flexible tubing. Lifecycle cost analysis often shows polyolefin elastomers providing better long-term value through superior performance and reduced maintenance despite the higher upfront investment.

Performance in End-Use Scenarios

Polyolefin elastomers exhibit superior flexibility, impact resistance, and elasticity, making them ideal for applications requiring deformation and recovery, such as automotive seals and flexible packaging. In contrast, polyolefin plastics offer higher rigidity, dimensional stability, and chemical resistance, suitable for structural components and rigid containers. Performance differences stem from their molecular structure, influencing durability and suitability across diverse end-use scenarios.

Future Trends in Polyolefin Material Innovation

Future trends in polyolefin material innovation emphasize enhancing mechanical performance and environmental sustainability through the development of advanced polyolefin elastomers (POEs) and polyolefin plastics. Research focuses on incorporating bio-based monomers and improving recyclability to reduce carbon footprints while maintaining or surpassing traditional polyolefin plastic properties. Innovations in catalyst technology and polymerization techniques are expected to drive tailored molecular architectures, enabling versatile applications across automotive, packaging, and medical industries.

Polyolefin Elastomer vs Polyolefin Plastic Infographic

libmatt.com

libmatt.com