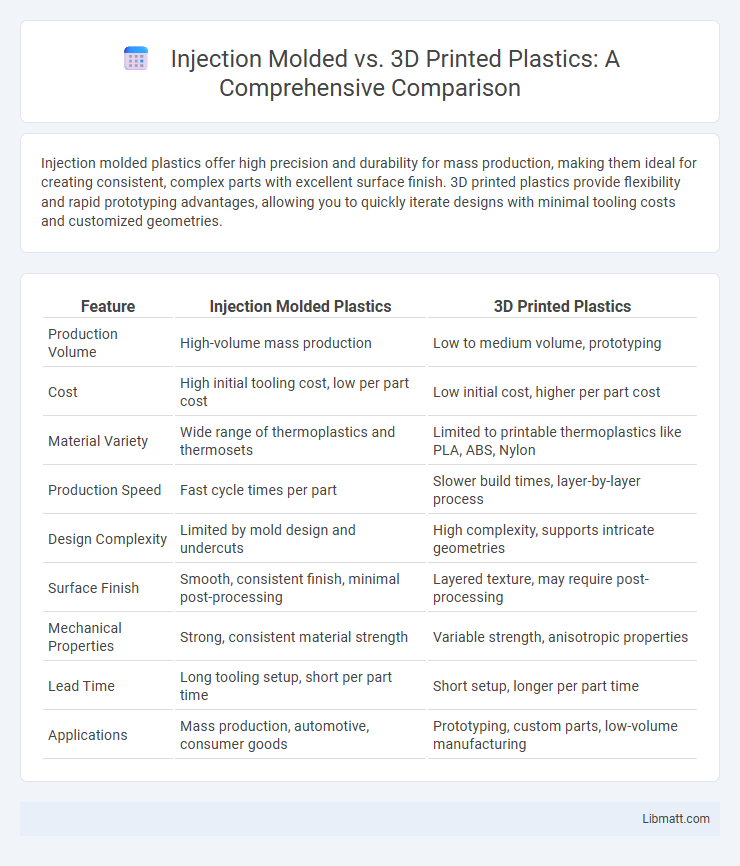

Injection molded plastics offer high precision and durability for mass production, making them ideal for creating consistent, complex parts with excellent surface finish. 3D printed plastics provide flexibility and rapid prototyping advantages, allowing you to quickly iterate designs with minimal tooling costs and customized geometries.

Table of Comparison

| Feature | Injection Molded Plastics | 3D Printed Plastics |

|---|---|---|

| Production Volume | High-volume mass production | Low to medium volume, prototyping |

| Cost | High initial tooling cost, low per part cost | Low initial cost, higher per part cost |

| Material Variety | Wide range of thermoplastics and thermosets | Limited to printable thermoplastics like PLA, ABS, Nylon |

| Production Speed | Fast cycle times per part | Slower build times, layer-by-layer process |

| Design Complexity | Limited by mold design and undercuts | High complexity, supports intricate geometries |

| Surface Finish | Smooth, consistent finish, minimal post-processing | Layered texture, may require post-processing |

| Mechanical Properties | Strong, consistent material strength | Variable strength, anisotropic properties |

| Lead Time | Long tooling setup, short per part time | Short setup, longer per part time |

| Applications | Mass production, automotive, consumer goods | Prototyping, custom parts, low-volume manufacturing |

Introduction to Injection Molded and 3D Printed Plastics

Injection molded plastics utilize high-pressure injection of molten material into metal molds, enabling mass production with consistent quality and low per-unit cost. 3D printed plastics employ additive manufacturing techniques, building parts layer by layer from digital models, ideal for rapid prototyping and complex geometries. Both methods serve diverse industries but differ significantly in scalability, material properties, and production speed.

Overview of Manufacturing Processes

Injection molded plastics involve heating thermoplastic pellets until molten and injecting the material into a precision-engineered metal mold under high pressure for rapid cooling and solidification, enabling mass production with consistent dimensional accuracy. 3D printed plastics rely on additive manufacturing techniques such as Fused Deposition Modeling (FDM) or Stereolithography (SLA), where plastic filament or resin is sequentially deposited or cured layer-by-layer based on digital 3D models, allowing for complex geometries and customization. Injection molding excels in high-volume runs with low per-unit cost, while 3D printing offers flexibility and fast prototyping without the need for tooling.

Material Selection and Compatibility

Injection molded plastics offer a wide range of material options, including ABS, polycarbonate, and polypropylene, known for their durability, heat resistance, and chemical stability. 3D printed plastics primarily utilize thermoplastics such as PLA, PETG, and nylon, with material properties highly dependent on the printing technology and filament quality. Material compatibility in injection molding allows for complex, multi-material assemblies, while 3D printing enables rapid prototyping with limited multi-material integration and variable mechanical properties.

Production Speed and Lead Time

Injection molded plastics offer significantly faster production speeds for high-volume manufacturing, with cycle times often measured in seconds per part, resulting in lead times that can be as short as a few days after mold creation. In contrast, 3D printed plastics typically have slower production speeds, as each part is built layer-by-layer, leading to longer lead times that range from several hours to days depending on complexity and batch size. For rapid prototyping or low-volume runs, 3D printing reduces upfront lead times since it does not require tooling, while injection molding excels in mass production efficiency once molds are finalized.

Cost Comparison: Short Run vs Mass Production

Injection molded plastics offer lower unit costs for mass production due to economies of scale and high initial tooling expenses, making them ideal for large volume runs. 3D printed plastics provide cost-effective solutions for short runs or prototyping, eliminating the need for expensive molds and allowing quick design iterations. Your choice depends on production volume and budget, with 3D printing favored for low quantities and injection molding preferred for high-volume manufacturing.

Design Flexibility and Complexity

Injection molded plastics excel in producing high-volume parts with consistent quality but face limitations in design complexity due to mold tooling constraints. 3D printed plastics offer exceptional design flexibility, enabling intricate geometries, internal structures, and rapid prototyping without the need for expensive molds. This makes 3D printing ideal for customized, complex parts and low-volume production runs where design iteration is critical.

Surface Finish and Dimensional Accuracy

Injection molded plastics offer superior surface finish with smooth, consistent textures and highly precise dimensional accuracy due to the controlled mold cavity environment. 3D printed plastics often exhibit layer lines and rougher surfaces, with dimensional accuracy varying based on the printing technology and material used, typically resulting in less uniformity. For applications demanding fine detail and tight tolerances, injection molding is preferred, whereas 3D printing suits prototyping or complex geometries where surface finish can be post-processed.

Strength, Durability, and Performance

Injection molded plastics exhibit superior strength and durability due to uniform material density and controlled production processes, making them ideal for high-performance applications requiring consistent structural integrity. 3D printed plastics offer versatility and rapid prototyping advantages but generally have lower mechanical strength and durability because of layer-by-layer construction, which can introduce weak points and anisotropic properties. Your choice between injection molded and 3D printed plastics depends on whether you prioritize long-term performance and production volume or customization and speed.

Environmental Impact and Sustainability

Injection molded plastics generally have a lower environmental impact on a per-unit basis due to their efficiency in mass production and material utilization, resulting in less waste compared to 3D printing processes. 3D printed plastics often consume more energy and generate higher emissions during production, but they offer sustainability advantages by enabling on-demand manufacturing and reducing inventory waste. You can enhance your product's sustainability by choosing injection molding for large-scale runs and 3D printing for customized, low-volume parts, balancing environmental impact with production needs.

Choosing the Right Process for Your Project

Selecting between injection molded and 3D printed plastics depends on project scale, complexity, and budget. Injection molding offers high-volume production with consistent quality and lower per-unit cost, ideal for large runs and standardized parts. 3D printing excels in rapid prototyping, customization, and low-volume production, enabling intricate designs and quick iterations without expensive tooling.

Injection Molded vs 3D Printed Plastics Infographic

libmatt.com

libmatt.com