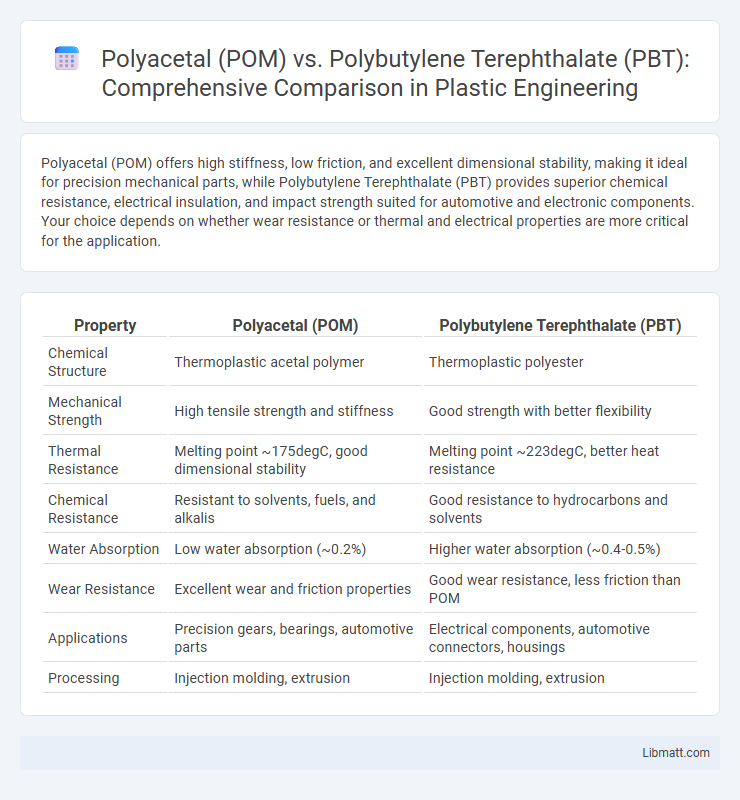

Polyacetal (POM) offers high stiffness, low friction, and excellent dimensional stability, making it ideal for precision mechanical parts, while Polybutylene Terephthalate (PBT) provides superior chemical resistance, electrical insulation, and impact strength suited for automotive and electronic components. Your choice depends on whether wear resistance or thermal and electrical properties are more critical for the application.

Table of Comparison

| Property | Polyacetal (POM) | Polybutylene Terephthalate (PBT) |

|---|---|---|

| Chemical Structure | Thermoplastic acetal polymer | Thermoplastic polyester |

| Mechanical Strength | High tensile strength and stiffness | Good strength with better flexibility |

| Thermal Resistance | Melting point ~175degC, good dimensional stability | Melting point ~223degC, better heat resistance |

| Chemical Resistance | Resistant to solvents, fuels, and alkalis | Good resistance to hydrocarbons and solvents |

| Water Absorption | Low water absorption (~0.2%) | Higher water absorption (~0.4-0.5%) |

| Wear Resistance | Excellent wear and friction properties | Good wear resistance, less friction than POM |

| Applications | Precision gears, bearings, automotive parts | Electrical components, automotive connectors, housings |

| Processing | Injection molding, extrusion | Injection molding, extrusion |

Introduction to Polyacetal (POM) and Polybutylene Terephthalate (PBT)

Polyacetal (POM) is a high-performance engineering thermoplastic known for its excellent mechanical properties, including high stiffness, low friction, and good dimensional stability. Polybutylene Terephthalate (PBT) is a semicrystalline thermoplastic polyester valued for its chemical resistance, electrical insulation properties, and dimensional stability under heat. Both materials are widely used in automotive, electrical, and industrial applications where strength and durability are critical.

Chemical Structure Comparison: POM vs PBT

Polyacetal (POM) features a repeating unit characterized by a methylene bridge (-CH2-) linked by oxygen atoms, resulting in a highly crystalline, linear polymer structure with excellent rigidity and low friction. Polybutylene Terephthalate (PBT) consists of ester groups (-COO-) connecting butylene glycol and terephthalic acid units, forming a semi-crystalline polymer known for its thermal stability and chemical resistance. The key difference lies in POM's acetal polymer backbone providing superior dimensional stability, while PBT's aromatic ester structure enhances toughness and moisture resistance.

Key Mechanical Properties of POM and PBT

Polyacetal (POM) offers high tensile strength, excellent stiffness, and superior wear resistance, making it ideal for precision parts requiring low friction and durability. Polybutylene Terephthalate (PBT) features good impact resistance, dimensional stability, and chemical resistance, suitable for electrical and automotive components exposed to heat and moisture. Both polymers exhibit notable mechanical strength, but POM excels in toughness and low friction, while PBT stands out in thermal stability and electrical insulation.

Thermal Performance: Heat Resistance in POM and PBT

Polyacetal (POM) exhibits excellent dimensional stability and maintains mechanical strength up to temperatures around 100-120degC, making it suitable for applications requiring moderate heat resistance. Polybutylene Terephthalate (PBT) offers superior thermal performance with a higher heat deflection temperature, typically ranging from 140-150degC, enabling better resistance in environments exposed to continuous heat. Your choice between POM and PBT should consider the specific temperature demands of your application, as PBT provides enhanced heat resistance while POM excels in lower-temperature mechanical stability.

Electrical Properties and Insulation Capabilities

Polyacetal (POM) exhibits excellent electrical insulation properties with a dielectric constant typically around 3.7 and a high volume resistivity exceeding 10^14 ohm-cm, making it ideal for precise electrical components. Polybutylene Terephthalate (PBT) offers superior electrical stability under thermal stress, with a dielectric constant often near 3.2 and strong resistance to electrical tracking and arcing. Both polymers provide robust insulation capabilities, but PBT is preferred in applications requiring higher thermal endurance and resistance to electrical degradation.

Chemical Resistance: POM vs PBT

Polyacetal (POM) exhibits excellent chemical resistance to solvents, fuels, and alkalis, making it ideal for automotive and mechanical applications. Polybutylene Terephthalate (PBT) is resistant to acids, oils, and hydrocarbons but can degrade in strong alkalis and certain solvents. POM generally outperforms PBT in environments demanding high resistance to polar solvents and bases.

Processing and Manufacturability

Polyacetal (POM) exhibits excellent machinability and dimensional stability, making it ideal for high-precision injection molding and CNC machining processes. Polybutylene Terephthalate (PBT) offers superior thermal resistance and chemical stability, enabling efficient molding with minimal warping and improved electrical insulation properties. Both materials allow for cost-effective mass production, though POM processes at slightly lower temperatures compared to PBT, influencing cycle times and mold design requirements.

Common Applications in Industry

Polyacetal (POM) is widely used in precision mechanical parts, automotive components, and electrical appliances due to its high stiffness, low friction, and excellent dimensional stability. Polybutylene Terephthalate (PBT) finds common applications in the electrical and electronics industry, including connectors, switches, and housings, owing to its superior electrical insulation properties and chemical resistance. Both materials are favored in industries requiring durability and performance, but POM excels in mechanical applications while PBT is preferred for electrical and electronic components.

Cost Analysis and Availability

Polyacetal (POM) generally offers lower raw material costs compared to Polybutylene Terephthalate (PBT), making it a cost-effective choice for high-precision components in automotive and consumer goods. POM has widespread global availability with a mature supply chain, whereas PBT's availability can be influenced by fluctuations in demand for polyester resins used in electronics and electrical applications. Manufacturing costs for POM tend to be lower due to simpler processing requirements, while PBT may incur higher expenses from moisture sensitivity and drying needs during production.

Choosing Between POM and PBT: Factors to Consider

Polyacetal (POM) and Polybutylene Terephthalate (PBT) differ significantly in mechanical strength, chemical resistance, and thermal stability, making selection dependent on specific application requirements. POM offers superior stiffness, low friction, and excellent dimensional stability, ideal for precision parts and wear-resistant components. PBT excels in electrical insulation and heat resistance, making it preferred for automotive connectors and electronic housings where thermal endurance and moisture resistance are critical.

Polyacetal (POM) vs Polybutylene Terephthalate (PBT) Infographic

libmatt.com

libmatt.com