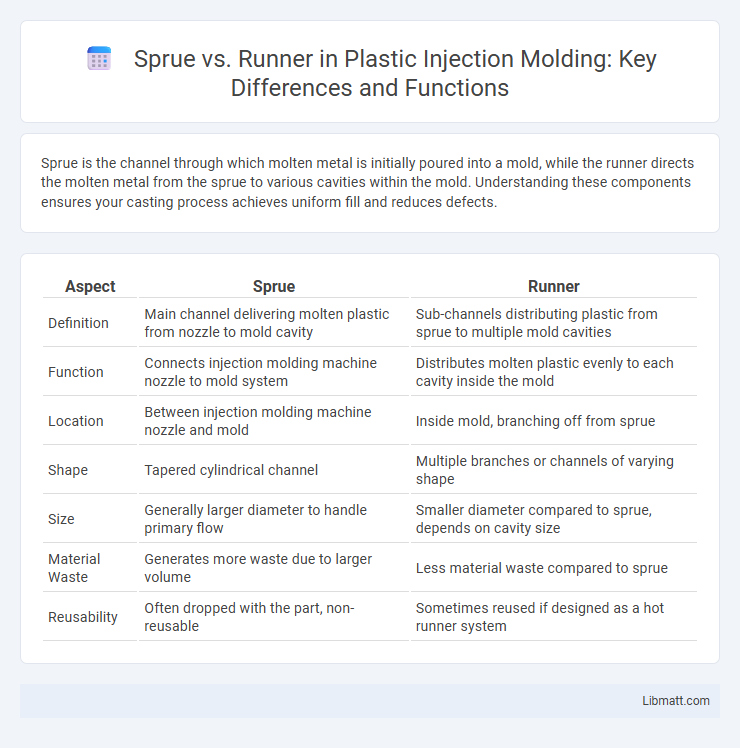

Sprue is the channel through which molten metal is initially poured into a mold, while the runner directs the molten metal from the sprue to various cavities within the mold. Understanding these components ensures your casting process achieves uniform fill and reduces defects.

Table of Comparison

| Aspect | Sprue | Runner |

|---|---|---|

| Definition | Main channel delivering molten plastic from nozzle to mold cavity | Sub-channels distributing plastic from sprue to multiple mold cavities |

| Function | Connects injection molding machine nozzle to mold system | Distributes molten plastic evenly to each cavity inside the mold |

| Location | Between injection molding machine nozzle and mold | Inside mold, branching off from sprue |

| Shape | Tapered cylindrical channel | Multiple branches or channels of varying shape |

| Size | Generally larger diameter to handle primary flow | Smaller diameter compared to sprue, depends on cavity size |

| Material Waste | Generates more waste due to larger volume | Less material waste compared to sprue |

| Reusability | Often dropped with the part, non-reusable | Sometimes reused if designed as a hot runner system |

Introduction to Sprue and Runner in Molding

Sprue and runner are essential components in injection molding, responsible for channeling molten material into the mold cavities. The sprue acts as the primary passage connecting the injection molding machine nozzle to the runner system, while runners distribute the material evenly to multiple mold cavities. Proper design of sprue and runner systems enhances filling efficiency, reduces material waste, and improves final product quality.

Defining Sprue: Function and Importance

The sprue is a crucial channel in casting molds that directs molten material from the pouring basin to the mold cavity, ensuring smooth and controlled flow. It functions as the primary pathway for molten metal or plastic, maintaining pressure and minimizing turbulence to reduce defects. Proper sprue design is essential for efficient filling, solidification, and overall quality of the final cast or molded product.

Understanding the Runner System

The runner system in injection molding acts as a channel that guides molten plastic from the sprue to the mold cavities, ensuring even distribution and reducing material waste. Unlike the sprue, which is the main entry point, runners branch out to direct flow efficiently to multiple parts. Understanding your runner system helps optimize cycle time, improve part quality, and minimize defects during production.

Key Differences Between Sprue and Runner

The sprue is the main channel through which molten metal flows from the pouring basin into the mold, serving as the primary passage during the casting process. Runners are secondary channels branching off from the sprue, directing metal to various parts of the mold and ensuring even distribution. Key differences include the sprue's vertical orientation and role in initial metal intake, while runners are horizontal channels that facilitate flow to specific mold cavities.

Material Flow: Sprue vs Runner

The sprue channels molten material from the injection molding machine nozzle into the mold, acting as the primary entry point and bearing the highest pressure and temperature. Runners distribute the molten material from the sprue to individual cavities, designed to maintain balanced flow and reduce turbulence for uniform cavity filling. Optimizing sprue and runner dimensions ensures efficient material flow, minimizes waste, and improves part quality by controlling cooling rates and solidification within the mold.

Design Considerations for Sprue and Runner

Design considerations for sprue and runner focus on optimizing flow efficiency and minimizing material waste during injection molding. The sprue must be designed with an appropriate diameter to reduce pressure drop, while runners require precise cross-sectional shapes to ensure uniform melt distribution and balanced filling of cavities. Properly engineered sprue and runner systems improve cycle times and enhance the quality of your molded parts by preventing defects such as air traps and incomplete fills.

Common Issues in Sprue and Runner Design

Common issues in sprue and runner design include improper sizing, which can lead to excessive pressure loss and incomplete mold filling. Uneven flow distribution caused by poorly designed runners results in defects such as warping and inconsistent part quality. Additionally, sharp corners and abrupt transitions in the runner system can cause turbulence and increased shear stress, affecting material flow and final product integrity.

Impact on Mold Efficiency and Product Quality

Sprue design directly influences mold efficiency by controlling the flow rate and minimizing material waste, while a well-optimized runner system ensures balanced filling and reduces cycle times, enhancing overall production speed. Improper sprue or runner sizing can cause defects like warping or incomplete fills, negatively affecting product quality and increasing scrap rates. Your choice of sprue and runner dimensions plays a crucial role in maintaining consistent mold performance and achieving superior molded parts.

Optimizing Sprue and Runner Systems

Optimizing sprue and runner systems is crucial for enhancing injection molding efficiency and reducing material waste. Properly sized sprues and runners ensure balanced flow, minimizing pressure drops and avoiding defects like warping or incomplete fills. You can improve cycle times and product quality by implementing computer-aided flow simulations and adjusting runner diameters for consistent material distribution.

Conclusion: Choosing the Right Approach

Choosing between a sprue and a runner depends on the specific casting process and desired efficiency. A sprue efficiently directs molten metal into the mold with minimal turbulence, while runners distribute metal evenly to multiple cavities for balanced filling. Your selection should prioritize mold design, casting complexity, and production goals to optimize quality and reduce defects.

Sprue vs runner Infographic

libmatt.com

libmatt.com