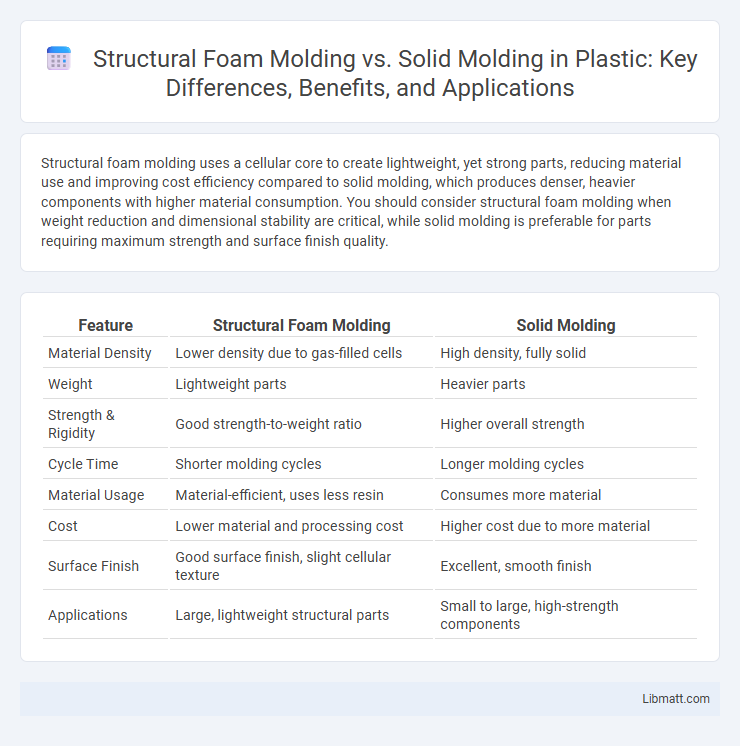

Structural foam molding uses a cellular core to create lightweight, yet strong parts, reducing material use and improving cost efficiency compared to solid molding, which produces denser, heavier components with higher material consumption. You should consider structural foam molding when weight reduction and dimensional stability are critical, while solid molding is preferable for parts requiring maximum strength and surface finish quality.

Table of Comparison

| Feature | Structural Foam Molding | Solid Molding |

|---|---|---|

| Material Density | Lower density due to gas-filled cells | High density, fully solid |

| Weight | Lightweight parts | Heavier parts |

| Strength & Rigidity | Good strength-to-weight ratio | Higher overall strength |

| Cycle Time | Shorter molding cycles | Longer molding cycles |

| Material Usage | Material-efficient, uses less resin | Consumes more material |

| Cost | Lower material and processing cost | Higher cost due to more material |

| Surface Finish | Good surface finish, slight cellular texture | Excellent, smooth finish |

| Applications | Large, lightweight structural parts | Small to large, high-strength components |

Introduction to Structural Foam Molding and Solid Molding

Structural foam molding uses a chemical blowing agent to create a cellular core within plastic parts, resulting in lightweight yet strong components with improved dimensional stability and reduced material usage. Solid molding involves molding fully dense, homogeneous plastic parts that offer maximum strength and durability but tend to be heavier and consume more raw material. Structural foam molding is ideal for large, complex parts requiring weight reduction, while solid molding suits applications demanding full structural integrity and surface finish quality.

Overview of the Molding Processes

Structural foam molding involves injecting a gas or chemical blowing agent into the molten plastic, creating a cellular core with a solid outer skin that offers high strength-to-weight ratio and reduced material usage. Solid molding, by contrast, uses completely solid plastic without any foaming agents, resulting in denser parts with greater rigidity and surface finish quality but higher material cost. Understanding the differences in wall thickness, cycle time, and mechanical properties can help optimize Your manufacturing process based on specific strength, weight, and cost requirements.

Material Compatibility and Selection

Structural foam molding accommodates a broader range of thermoplastic materials, including polypropylene, polyethylene, and ABS, allowing for lightweight parts with enhanced strength-to-weight ratios. In contrast, solid molding typically utilizes denser materials such as nylon and polycarbonate, which provide superior mechanical properties and surface finish but increase part weight. Material selection depends on application requirements, with structural foam offering cost-effective solutions for large, complex geometries, while solid molding suits components needing high strength and precision.

Design Flexibility and Part Complexity

Structural foam molding offers greater design flexibility and enables the creation of complex, hollow parts with reduced weight compared to solid molding. Solid molding produces denser, more uniform parts but limits intricate internal geometries due to slower cooling rates and higher material use. Engineers prefer structural foam molding for lightweight components with complex shapes, while solid molding suits applications requiring higher strength and precision.

Strength and Weight Comparisons

Structural foam molding produces lighter parts with a cellular core, maintaining strength while significantly reducing weight compared to solid molding, which results in denser and heavier components. Your project benefits from structural foam's improved strength-to-weight ratio, ideal for applications requiring durability without added mass. Solid molding, however, excels in high-strength requirements where maximum material density enhances load-bearing capacity.

Surface Finish and Aesthetic Considerations

Structural foam molding produces parts with a smooth, uniform surface that often requires minimal post-processing, making it ideal for visually appealing applications. Solid molding typically offers a more consistent density throughout the part, resulting in a higher-quality surface finish that supports intricate details and vibrant colors. When choosing between the two, your preference for surface texture and aesthetic precision will guide the best molding method for your product design.

Production Speed and Cycle Times

Structural foam molding offers faster production speeds and shorter cycle times compared to solid molding due to its lightweight core and reduced cooling requirements. The expanded polymer core in structural foam allows for quicker cooling and solidification, increasing throughput and efficiency. Your manufacturing process can benefit from these advantages by reducing production bottlenecks and improving overall output.

Cost Efficiency and Economic Factors

Structural foam molding offers significant cost efficiency by reducing material usage through its hollow core design, lowering raw material expenses compared to solid molding. The shorter cycle times and decreased tool wear associated with structural foam molding further contribute to economic savings in high-volume production. In contrast, solid molding incurs higher material costs and longer cycle times, which increase overall manufacturing expenses despite providing superior part strength.

Common Applications in Industry

Structural foam molding finds common applications in automotive parts, marine components, and large appliance housings due to its lightweight yet strong characteristics. Solid molding is widely used in high-strength applications such as aerospace components, industrial machinery parts, and tools requiring maximum durability. Your choice between these methods depends on the balance needed between weight reduction and structural integrity in your manufacturing process.

Choosing the Best Method for Your Project

Structural foam molding offers lightweight parts with excellent strength-to-weight ratio, ideal for large components and reducing material costs, while solid molding provides higher density and superior mechanical properties for intricate, high-strength applications. Your choice depends on project requirements such as load-bearing capacity, weight restrictions, and budget constraints, where structural foam is suited for moderate strength needs and solid molding excels in durability. Consider production volume and finish quality to determine the best molding process for optimal performance and cost-efficiency in your project.

Structural foam molding vs solid molding Infographic

libmatt.com

libmatt.com