Gate vestige is the small mark or raised area left on a plastic part where the molten material entered the mold, often causing minor aesthetic imperfections. Weld lines occur when two flow fronts meet and fail to fuse properly, potentially weakening the part structurally and affecting its mechanical performance.

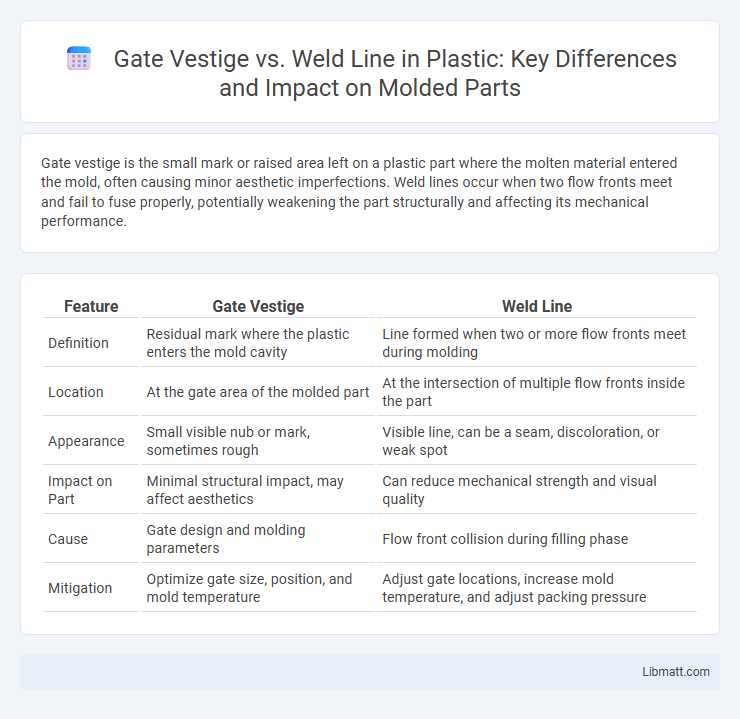

Table of Comparison

| Feature | Gate Vestige | Weld Line |

|---|---|---|

| Definition | Residual mark where the plastic enters the mold cavity | Line formed when two or more flow fronts meet during molding |

| Location | At the gate area of the molded part | At the intersection of multiple flow fronts inside the part |

| Appearance | Small visible nub or mark, sometimes rough | Visible line, can be a seam, discoloration, or weak spot |

| Impact on Part | Minimal structural impact, may affect aesthetics | Can reduce mechanical strength and visual quality |

| Cause | Gate design and molding parameters | Flow front collision during filling phase |

| Mitigation | Optimize gate size, position, and mold temperature | Adjust gate locations, increase mold temperature, and adjust packing pressure |

Introduction to Gate Vestige and Weld Line

Gate vestige refers to the small mark or residue left on a molded part where the plastic enters the mold cavity through the gate, often impacting surface aesthetics but generally not structural integrity. Weld line occurs where two or more melt fronts meet and fail to bond completely during injection molding, potentially causing weak spots that affect part strength and durability. Both gate vestige and weld line are critical considerations in injection molding design and quality control, influencing the final product's appearance and mechanical performance.

Definitions: Gate Vestige vs Weld Line

Gate vestige refers to the small mark or residue left on a molded part at the point where molten material enters the mold cavity through the gate. Weld line, also known as a knit line, forms where two or more flow fronts of molten material meet and solidify, often causing a visible line or weak spot in the molded product. Both defects impact the aesthetic and structural integrity of injection-molded parts but originate from different stages of the molding process.

Causes and Formation Mechanisms

Gate vestige forms due to incomplete or improper gate removal during injection molding, resulting in a small raised mark where the plastic flows into the mold cavity. Weld lines occur when two or more flow fronts of molten plastic meet but fail to fuse completely, often caused by variations in temperature, pressure, or flow rate. Understanding these formation mechanisms helps you optimize mold design and processing parameters to minimize defects in molded parts.

Visual Differences and Identification

Gate vestige appears as a small, raised mark or nub at the injection point on the molded part, often round or slightly irregular in shape, making it easier to visually locate. Weld lines manifest as visible linear seams or streaks where two flow fronts meet, resulting in a subtle discoloration or surface irregularity that can sometimes be mistaken for a crack. Identifying gate vestige involves inspecting the part's gate location for a concentrated blemish, while weld lines are identified by scanning across the flow path for consistent lines often perpendicular to the direction of material flow.

Impact on Product Strength and Durability

The gate vestige and weld line both affect product strength and durability, with the gate vestige typically creating a localized weakness due to stress concentration and potential surface defects. Weld lines form where two flow fronts meet, often resulting in reduced mechanical strength and increased susceptibility to cracking under load. Proper molding design and process optimization are essential to minimize these defects and enhance the overall structural integrity of the final product.

Effects on Surface Finish and Aesthetics

Gate vestige often leaves a small, visible mark or protrusion on the surface of molded parts, which can affect the overall aesthetic quality and may require secondary finishing processes to achieve a smooth appearance. Weld lines, formed where two flow fronts meet during molding, typically result in visible lines or marks that can disrupt the uniformity of the surface finish, potentially weakening the part structurally and visually. Both defects impact the visual appeal of injection molded components, but weld lines tend to have a more pronounced effect on surface integrity and aesthetics due to their linear nature and potential for discoloration.

Troubleshooting and Prevention Methods

Gate vestige and weld line issues often stem from improper mold design or processing parameters, causing cosmetic defects and potential structural weaknesses in molded parts. Troubleshooting involves adjusting injection speed, temperature, and pressure to improve melt flow and reduce vestige size, while optimizing gate location minimizes weld line appearance. Preventing these defects requires regularly maintaining molds, utilizing balanced gate designs, and conducting flow simulations to ensure uniform filling and enhance Your part quality.

Material and Process Considerations

Gate vestige and weld line formation both significantly impact the quality of injection-molded parts, with material selection playing a crucial role in their appearance and strength. Materials with high flowability and thermal stability, such as ABS or polycarbonate, tend to minimize visible gate vestige and reduce weld line weaknesses during the molding process. Your process parameters, including injection speed, temperature, and mold design, must be optimized to balance material flow and cooling rates, ensuring minimal defects and maintaining part integrity.

Quality Control and Inspection Techniques

Gate vestige and weld lines significantly impact injection molded part aesthetics and structural integrity, requiring meticulous quality control and inspection techniques. Visual inspection, microscopy, and ultrasonic scanning are commonly used to detect gate vestige remnants and weld line defects, ensuring surface smoothness and internal consistency. Your quality control process benefits from automated optical inspection combined with destructive testing for comprehensive evaluation of potential weak points.

Conclusion: Gate Vestige vs Weld Line in Injection Molding

Gate vestige and weld line both affect the aesthetic and structural quality of injection molded parts, but they differ in appearance and impact; gate vestige is a small mark left after gate removal, while weld lines occur where two flow fronts meet, potentially weakening the part. Managing gate vestige involves optimizing gate design and trimming techniques, whereas minimizing weld lines requires controlling flow patterns, temperature, and injection speed. Your choice of process parameters and mold design directly influences the prominence and severity of these defects, ultimately determining part performance and visual appeal.

Gate vestige vs weld line Infographic

libmatt.com

libmatt.com