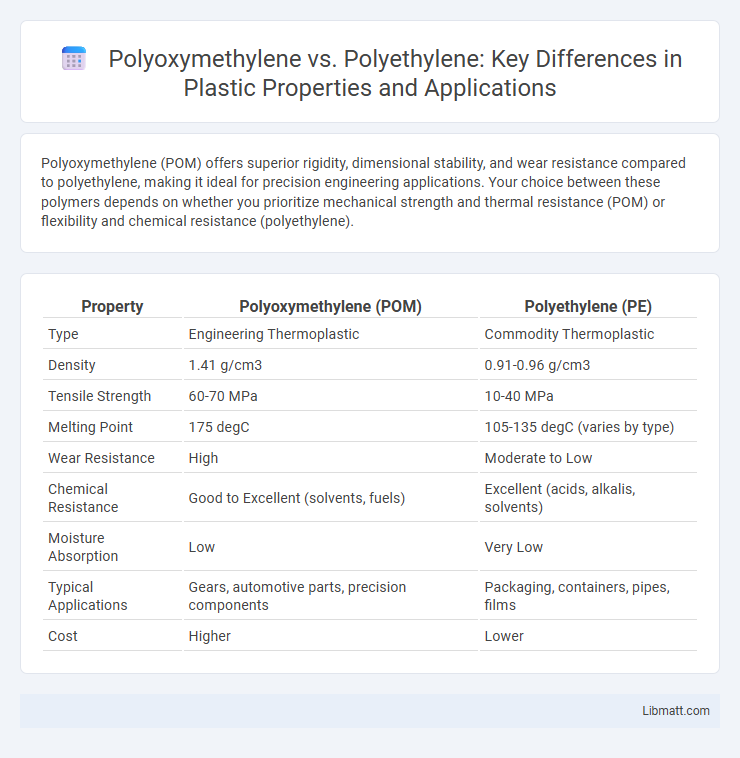

Polyoxymethylene (POM) offers superior rigidity, dimensional stability, and wear resistance compared to polyethylene, making it ideal for precision engineering applications. Your choice between these polymers depends on whether you prioritize mechanical strength and thermal resistance (POM) or flexibility and chemical resistance (polyethylene).

Table of Comparison

| Property | Polyoxymethylene (POM) | Polyethylene (PE) |

|---|---|---|

| Type | Engineering Thermoplastic | Commodity Thermoplastic |

| Density | 1.41 g/cm3 | 0.91-0.96 g/cm3 |

| Tensile Strength | 60-70 MPa | 10-40 MPa |

| Melting Point | 175 degC | 105-135 degC (varies by type) |

| Wear Resistance | High | Moderate to Low |

| Chemical Resistance | Good to Excellent (solvents, fuels) | Excellent (acids, alkalis, solvents) |

| Moisture Absorption | Low | Very Low |

| Typical Applications | Gears, automotive parts, precision components | Packaging, containers, pipes, films |

| Cost | Higher | Lower |

Introduction to Polyoxymethylene and Polyethylene

Polyoxymethylene (POM), also known as acetal, is a high-performance engineering thermoplastic known for its excellent mechanical strength, stiffness, and low friction properties, making it ideal for precision parts and automotive components. Polyethylene (PE) is a versatile, widely used polymer characterized by its chemical resistance, flexibility, and impact strength, commonly found in packaging, containers, and piping. Understanding the distinct properties of Polyoxymethylene and Polyethylene helps you select the right material for applications requiring either durability and rigidity or flexibility and chemical resistance.

Chemical Structure Comparison

Polyoxymethylene (POM) features a repeating unit of -CH2-O-, forming a highly crystalline structure that provides excellent stiffness and low friction. Polyethylene (PE) consists of long chains of -CH2- units, resulting in a more flexible, less dense polymer compared to POM. Understanding the distinct chemical structures helps you choose the right polymer for applications requiring either rigidity or flexibility.

Mechanical Properties: Strength and Durability

Polyoxymethylene (POM) exhibits higher tensile strength and superior stiffness compared to polyethylene (PE), making it ideal for precision mechanical parts requiring rigidity. POM's excellent fatigue resistance and low wear rate enhance its durability under repeated stress, whereas polyethylene offers better impact resistance but lower mechanical strength. The crystalline structure of POM contributes to its dimensional stability, contrasting with polyethylene's flexibility and susceptibility to deformation under heavy loads.

Thermal Stability and Operating Temperatures

Polyoxymethylene (POM) exhibits superior thermal stability with a continuous use temperature typically up to 100-110degC, whereas polyethylene (PE) varies widely but generally withstands up to 80-90degC for high-density grades. POM's crystalline structure offers higher melting points around 175degC compared to PE's melting range of 120-135degC for HDPE and 105-115degC for LDPE. These thermal properties make POM ideal for applications requiring higher heat resistance and dimensional stability under elevated temperatures compared to polyethylene.

Resistance to Chemicals and Solvents

Polyoxymethylene (POM) exhibits superior resistance to a wide range of chemicals and solvents, including alcohols, hydrocarbons, and dilute acids, making it ideal for precision parts exposed to harsh environments. In contrast, Polyethylene (PE) offers good resistance to many chemicals but tends to swell or degrade when exposed to strong oxidizing agents and certain solvents like aromatic hydrocarbons. Understanding these differences helps you select the best material for applications requiring reliable chemical stability and solvent resistance.

Processing Methods and Ease of Fabrication

Polyoxymethylene (POM) offers excellent dimensional stability and high rigidity, making it suitable for precision molding processes like injection molding and extrusion, which result in smooth surface finishes and tight tolerances. Polyethylene (PE), especially in its low-density forms, is easier to process due to its lower melting temperature and greater flexibility, allowing methods such as blow molding, rotational molding, and film extrusion with reduced energy consumption. Understanding the differences in processing methods and fabrication ease helps optimize your manufacturing decisions for applications requiring strength or flexibility.

Typical Applications in Industry

Polyoxymethylene (POM) is extensively used in precision mechanical parts such as gears, bearings, and automotive components due to its high stiffness, low friction, and excellent dimensional stability. Polyethylene (PE) dominates packaging applications, including plastic bags, bottles, and containers, benefiting from its flexibility, chemical resistance, and moisture barrier properties. Both polymers find roles in electrical insulation and consumer goods but serve distinct industrial needs based on their mechanical and chemical performance.

Cost Analysis and Availability

Polyoxymethylene (POM) generally costs more than polyethylene (PE) due to its superior mechanical properties and higher production complexity. Polyethylene is widely available and produced in large volumes globally, making it more cost-effective for bulk applications. Your choice depends on budget constraints and the specific performance requirements of the intended use.

Environmental Impact and Recyclability

Polyoxymethylene (POM) offers higher mechanical strength and durability but presents challenges in recycling due to limited recycling facilities and complex chemical structure. Polyethylene (PE), widely used in packaging, has well-established recycling streams and higher environmental recovery rates despite contributing significantly to plastic waste pollution. Both materials require improved recycling technologies to minimize environmental impact and promote circular economy practices.

Choosing the Right Polymer: Key Considerations

Polyoxymethylene (POM) offers superior mechanical strength, rigidity, and dimensional stability compared to polyethylene (PE), making it ideal for precision components and applications requiring high wear resistance. Polyethylene excels in chemical resistance, flexibility, and impact strength, suitable for packaging, containers, and insulation. When choosing the right polymer, consider your product's mechanical load, environmental exposure, and desired durability to ensure optimal performance and longevity.

Polyoxymethylene vs Polyethylene Infographic

libmatt.com

libmatt.com