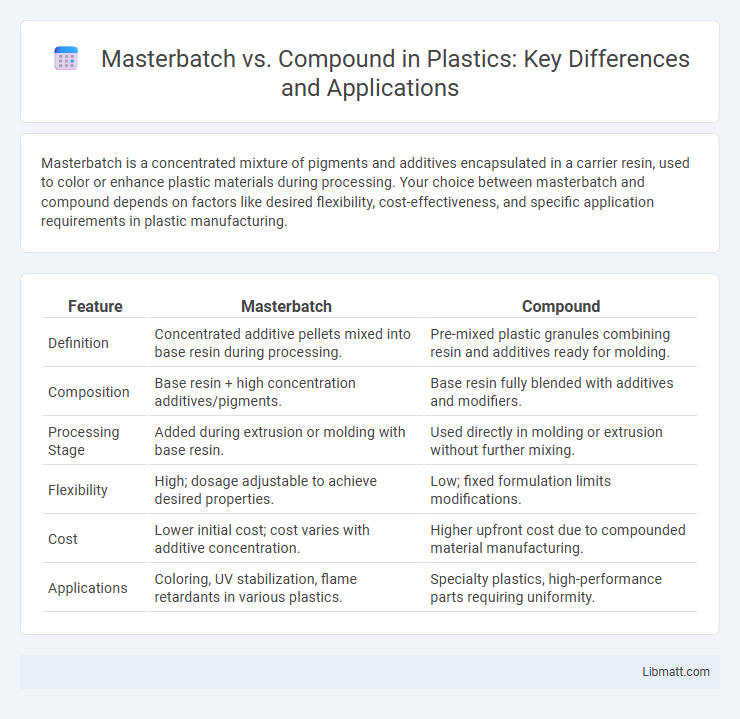

Masterbatch is a concentrated mixture of pigments and additives encapsulated in a carrier resin, used to color or enhance plastic materials during processing. Your choice between masterbatch and compound depends on factors like desired flexibility, cost-effectiveness, and specific application requirements in plastic manufacturing.

Table of Comparison

| Feature | Masterbatch | Compound |

|---|---|---|

| Definition | Concentrated additive pellets mixed into base resin during processing. | Pre-mixed plastic granules combining resin and additives ready for molding. |

| Composition | Base resin + high concentration additives/pigments. | Base resin fully blended with additives and modifiers. |

| Processing Stage | Added during extrusion or molding with base resin. | Used directly in molding or extrusion without further mixing. |

| Flexibility | High; dosage adjustable to achieve desired properties. | Low; fixed formulation limits modifications. |

| Cost | Lower initial cost; cost varies with additive concentration. | Higher upfront cost due to compounded material manufacturing. |

| Applications | Coloring, UV stabilization, flame retardants in various plastics. | Specialty plastics, high-performance parts requiring uniformity. |

Introduction to Masterbatch and Compound

Masterbatch is a concentrated mixture of pigments and additives encapsulated in a carrier resin, used to color or enhance plastic products during the manufacturing process. Compound refers to a pre-mixed combination of polymers and additives tailored to provide specific mechanical and physical properties in the final plastic product. Both masterbatch and compound play essential roles in plastic processing, with masterbatch focusing on color and additive dispersion, while compound integrates performance-enhancing components directly into the polymer matrix.

Definition and Composition Differences

Masterbatch is a concentrated mixture of pigments and additives encapsulated in a carrier resin used to color or enhance the properties of plastics during processing. Compound consists of plastic resin blended with additives, fillers, or reinforcements uniformly mixed to produce a material with specific mechanical or thermal characteristics. The primary difference lies in masterbatch serving as a colorant or additive concentrate, while compound is a ready-to-use engineered plastic material with modified properties.

Manufacturing Processes Compared

Masterbatch is produced by dispersing pigments and additives into a carrier resin through processes like extrusion and pelletizing, allowing for precise color or property modification in base polymers. Compound manufacturing involves melting and blending base polymers with additives and fillers using twin-screw extruders or internal mixers, resulting in a homogenized material with enhanced performance characteristics. The key difference lies in masterbatch serving as a concentrated additive source, whereas compounds are fully formulated materials ready for direct processing.

Key Applications in Various Industries

Masterbatch is predominantly used in industries such as packaging, automotive, and textiles for consistent color, additives, and improved material properties, while compounds find key applications in complex manufacturing requiring customized polymer blends like medical devices and electronics. Your production process benefits from masterbatch's ease of use and cost-efficiency in large-scale color or additive distribution, whereas compounds offer enhanced performance for specialized or technical parts due to tailored formulations. Both materials are critical in sectors ranging from construction to consumer goods, addressing requirements for durability, flexibility, and aesthetics.

Advantages of Using Masterbatch

Masterbatch offers precise color control and consistent dispersion, enhancing the quality and appearance of your plastic products. It simplifies the manufacturing process by adding pigments and additives in concentrated form, reducing labor and equipment cleaning times. Using masterbatch improves process efficiency, lowers material wastage, and allows for easy customization of product properties.

Benefits of Using Compound

Compound offers enhanced material properties by combining polymers with additives to improve strength, flexibility, and thermal stability, resulting in superior performance for specialized applications. Using compound reduces the need for multiple processing steps, saving time and costs in manufacturing while ensuring consistent quality. Your production benefits from increased efficiency and product customization, making compound a versatile choice for advanced plastic products.

Cost Comparison: Masterbatch vs Compound

Masterbatch typically offers a lower upfront cost compared to compounds due to its concentrated additive form, allowing processors to add precise amounts during production without purchasing pre-mixed materials. Compounds incur higher initial costs as they come pre-mixed with additives and base polymers, increasing inventory expenses and reducing flexibility in formulation adjustments. Over time, masterbatch can reduce overall production costs by minimizing waste and enabling on-demand customization, while compounds may streamline processing but at the expense of higher raw material investments.

Performance and Quality Considerations

Masterbatch offers consistent color dispersion and additive distribution essential for achieving uniform product quality in plastic manufacturing. Compounds provide enhanced mechanical properties by integrating base resin with additives during compounding, resulting in superior performance characteristics tailored to specific applications. Selecting between masterbatch and compound depends on the desired balance between process flexibility, cost efficiency, and end-product performance requirements.

Environmental Impact and Sustainability

Masterbatch and compound differ significantly in environmental impact and sustainability; masterbatch typically reduces waste and energy consumption by enabling precise pigment dosing during manufacturing, minimizing excess material usage. Compounds, incorporating pigments or additives directly into the polymer blend, often require higher processing energy and generate more scrap due to less flexibility in color or additive changes. Selecting masterbatch enhances recyclability and eco-efficiency by simplifying material sorting and recycling processes compared to compounded materials.

Choosing the Right Solution for Your Needs

Masterbatch offers concentrated pigments or additives dispersed in a carrier resin, ideal for flexible color and property adjustments in plastics processing, ensuring consistent quality and efficient use. Compounds combine base resin with additives or fillers in precise formulations, providing enhanced mechanical properties or specialized functionalities tailored to specific applications. Selecting the right solution depends on production scale, complexity of additive integration, and performance requirements to optimize cost-effectiveness and product performance.

Masterbatch vs Compound Infographic

libmatt.com

libmatt.com