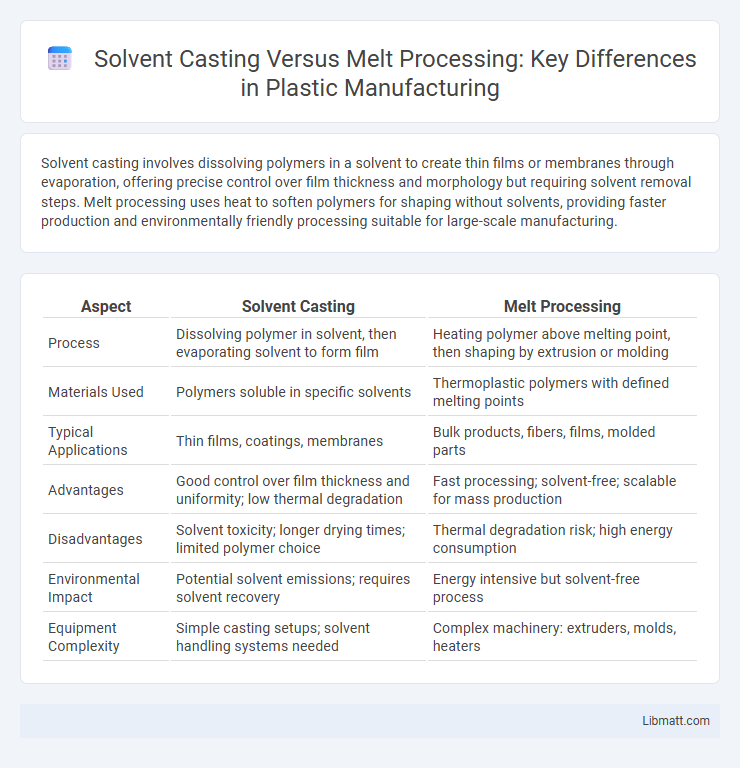

Solvent casting involves dissolving polymers in a solvent to create thin films or membranes through evaporation, offering precise control over film thickness and morphology but requiring solvent removal steps. Melt processing uses heat to soften polymers for shaping without solvents, providing faster production and environmentally friendly processing suitable for large-scale manufacturing.

Table of Comparison

| Aspect | Solvent Casting | Melt Processing |

|---|---|---|

| Process | Dissolving polymer in solvent, then evaporating solvent to form film | Heating polymer above melting point, then shaping by extrusion or molding |

| Materials Used | Polymers soluble in specific solvents | Thermoplastic polymers with defined melting points |

| Typical Applications | Thin films, coatings, membranes | Bulk products, fibers, films, molded parts |

| Advantages | Good control over film thickness and uniformity; low thermal degradation | Fast processing; solvent-free; scalable for mass production |

| Disadvantages | Solvent toxicity; longer drying times; limited polymer choice | Thermal degradation risk; high energy consumption |

| Environmental Impact | Potential solvent emissions; requires solvent recovery | Energy intensive but solvent-free process |

| Equipment Complexity | Simple casting setups; solvent handling systems needed | Complex machinery: extruders, molds, heaters |

Introduction to Solvent Casting and Melt Processing

Solvent casting involves dissolving polymers in a suitable solvent to form a homogeneous solution, which is then cast into a film or shape before solvent evaporation solidifies the material. Melt processing, by contrast, heats polymers above their melting point to shape them through extrusion, injection molding, or compression without using solvents. These methods differ significantly in terms of processing conditions, polymer compatibility, and final material properties.

Overview of Polymer Processing Techniques

Solvent casting involves dissolving polymers in a suitable solvent to form a solution, which is then cast into a film and dried to remove the solvent, making it ideal for creating thin, uniform coatings or membranes. Melt processing heats the polymer above its melting point and shapes it through extrusion, injection molding, or compression, offering efficient production of durable and complex shapes without solvent residues. Your choice between solvent casting and melt processing depends on polymer properties, product application, and environmental considerations in manufacturing.

Principles of Solvent Casting

Solvent casting relies on dissolving polymers in suitable solvents to create a uniform solution, which is then poured into molds and dried to form thin films or membranes. The drying process evaporates the solvent, leaving behind a solid polymer matrix with controlled porosity and morphology. This technique offers precise control over film thickness and surface properties, essential for applications in drug delivery and biodegradable materials.

Principles of Melt Processing

Melt processing involves heating polymers until they become molten, enabling shaping through extrusion, injection molding, or compression molding. This method allows precise control over temperature and shear rates, affecting the polymer's crystallinity and mechanical properties. Your choice of melt processing parameters directly influences the final product's strength, clarity, and thermal stability.

Key Differences Between Solvent Casting and Melt Processing

Solvent casting involves dissolving a polymer in a suitable solvent to form a film, enabling precise control over the thickness and uniformity of the material, whereas melt processing heats the polymer until it becomes molten and then shapes it through extrusion or molding. Solvent casting is preferred for polymers sensitive to high temperatures, while melt processing suits thermoplastics that can withstand heat without degradation. Your choice depends on factors like polymer type, desired film properties, and processing feasibility, impacting the final product's mechanical and thermal characteristics.

Advantages of Solvent Casting

Solvent casting offers precise control over film thickness and uniformity, making it ideal for producing thin, flexible polymer films with consistent properties. The process enables the incorporation of temperature-sensitive additives and active compounds without degradation, ensuring high-quality end products. Your ability to produce homogenous films with tailored microstructures can enhance performance in biomedical, packaging, and electronic applications.

Benefits of Melt Processing

Melt processing offers significant benefits such as eliminating the need for solvents, which reduces environmental impact and health risks associated with volatile organic compounds. It enables faster production cycles and improved scalability for manufacturing polymers and composite materials. Your choice of melt processing can enhance material uniformity and mechanical properties due to precise temperature and shear control during processing.

Typical Applications in Industry

Solvent casting finds extensive use in pharmaceutical manufacturing for creating controlled-release drug delivery systems and thin polymer films due to its ability to produce uniform and flexible membranes. Melt processing dominates industries like packaging, automotive, and textiles by enabling large-scale production of polymer-based products such as films, fibers, and molded components with high mechanical strength. Your choice between solvent casting and melt processing depends on the desired product properties, scalability, and application requirements within sectors like biomedical devices or consumer goods.

Environmental and Safety Considerations

Solvent casting involves the use of organic solvents that pose environmental hazards due to volatile organic compound (VOC) emissions and require strict safety measures to prevent inhalation and fire risks. Melt processing eliminates solvent use, reducing environmental impact and exposure to toxic fumes, but involves high temperatures that demand proper thermal safety protocols to prevent burns and equipment hazards. Choosing melt processing over solvent casting significantly lowers chemical waste and solvent recovery challenges, enhancing overall environmental and workplace safety.

Choosing the Right Method for Your Application

Solvent casting offers precise control over film thickness and is ideal for heat-sensitive materials, while melt processing excels in scalability and cost-effectiveness for thermoplastic polymers. Selecting the appropriate method depends on material properties, desired product characteristics, and production volume. Understanding the trade-offs between solvent use and thermal stability ensures optimal application performance and environmental compliance.

Solvent Casting vs Melt Processing Infographic

libmatt.com

libmatt.com