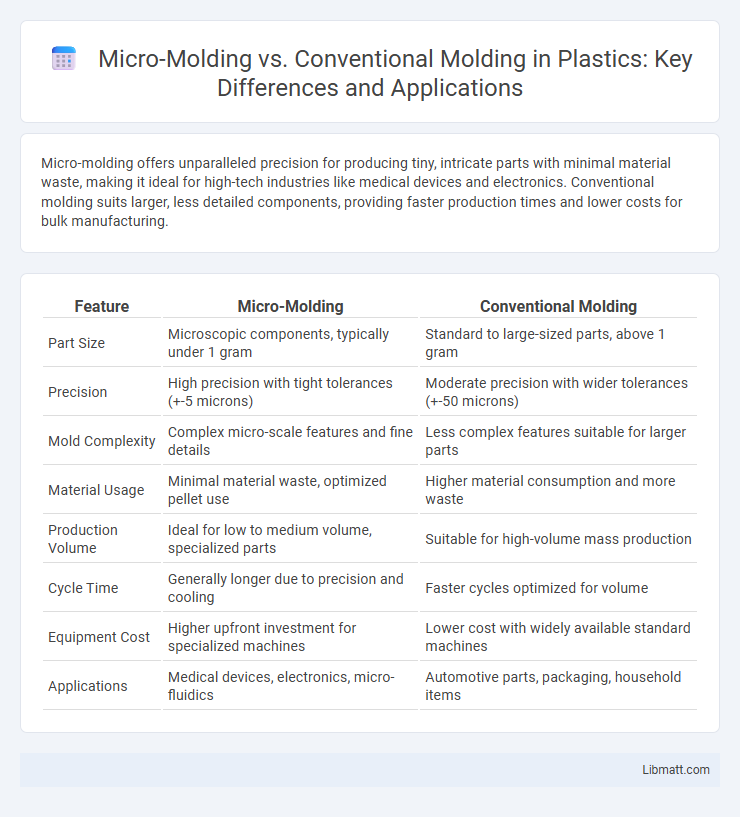

Micro-molding offers unparalleled precision for producing tiny, intricate parts with minimal material waste, making it ideal for high-tech industries like medical devices and electronics. Conventional molding suits larger, less detailed components, providing faster production times and lower costs for bulk manufacturing.

Table of Comparison

| Feature | Micro-Molding | Conventional Molding |

|---|---|---|

| Part Size | Microscopic components, typically under 1 gram | Standard to large-sized parts, above 1 gram |

| Precision | High precision with tight tolerances (+-5 microns) | Moderate precision with wider tolerances (+-50 microns) |

| Mold Complexity | Complex micro-scale features and fine details | Less complex features suitable for larger parts |

| Material Usage | Minimal material waste, optimized pellet use | Higher material consumption and more waste |

| Production Volume | Ideal for low to medium volume, specialized parts | Suitable for high-volume mass production |

| Cycle Time | Generally longer due to precision and cooling | Faster cycles optimized for volume |

| Equipment Cost | Higher upfront investment for specialized machines | Lower cost with widely available standard machines |

| Applications | Medical devices, electronics, micro-fluidics | Automotive parts, packaging, household items |

Introduction to Micro-Molding and Conventional Molding

Micro-molding involves producing extremely small, precise components using specialized equipment that enables high-resolution shaping of materials, whereas conventional molding focuses on larger, less detailed parts typically manufactured through standard injection or compression molding processes. Micro-molding allows for intricate features and tight tolerances in industries such as medical devices and electronics, while conventional molding suits automotive, consumer goods, and packaging applications with broader size and tolerance requirements. Both methods use thermoplastics or thermosetting polymers but differ significantly in scale, precision, and tooling complexity.

Key Differences Between Micro-Molding and Conventional Molding

Micro-molding differs from conventional molding mainly in scale, precision, and application, producing components typically under 1 gram with features in micrometer ranges, whereas conventional molding handles larger parts with less detailed accuracy. Micro-molding requires advanced machinery and molds with fine tolerances to achieve intricate geometries, making it ideal for medical devices and microelectronics, while conventional molding suits broader manufacturing needs with robust, cost-effective processes. Your choice between these methods hinges on the complexity, size, and required precision of the final component.

Materials Used in Micro-Molding vs Conventional Molding

Micro-molding typically utilizes high-precision thermoplastics, silicone, and specialized metals designed for intricate, small-scale applications, whereas conventional molding employs a broader range of materials including standard plastics, rubber, and metals suited for larger, less detailed parts. The choice of materials in micro-molding demands superior flow characteristics and thermal stability to achieve microscopic features, while conventional molding focuses more on durability and cost-effectiveness. Understanding your material requirements ensures optimal performance and quality in either micro-molding or conventional molding processes.

Process Precision and Tolerances

Micro-molding offers significantly higher process precision and tighter tolerances compared to conventional molding, enabling the production of intricate components with features often less than 1 millimeter. This advanced technique reduces material waste and enhances dimensional accuracy, which is critical for applications in medical devices and electronics where minute details are crucial. Your manufacturing process benefits from micro-molding's ability to replicate complex micro-scale geometries consistently, ensuring superior quality and performance.

Applications and Industries Served

Micro-molding excels in producing highly precise, tiny components critical for medical devices, electronics, and automotive sensors, where accuracy and miniaturization are essential. Conventional molding is widely used in industries such as automotive, packaging, and consumer goods for larger, less intricate parts requiring high-volume production. Both methods serve diverse sectors, but micro-molding specializes in microelectronics and biomedical applications with stringent dimensional tolerances.

Advantages of Micro-Molding

Micro-molding offers exceptional precision and the ability to create extremely small and complex parts that conventional molding cannot achieve. It reduces material waste and enhances production efficiency, making it ideal for high-volume manufacturing of intricate components. Your projects benefit from improved accuracy and faster turnaround times, especially in industries like medical devices, electronics, and micro-mechanics.

Limitations of Conventional Molding in Micro Applications

Conventional molding faces significant limitations in micro applications due to its inability to achieve the required precision and intricate details at the microscopic scale, often resulting in lower dimensional accuracy and higher defect rates. The process struggles with producing extremely small, complex geometries and fine features, leading to challenges in material flow and mold filling. Your projects demanding tight tolerances and miniature components benefit more from micro-molding technologies designed specifically to overcome these constraints.

Cost Comparison: Micro-Molding vs Conventional Molding

Micro-molding typically involves higher initial setup costs due to the precision equipment and specialized tooling required, making it more expensive upfront compared to conventional molding. However, micro-molding offers significant cost savings in producing small, intricate parts with minimal material waste and faster cycle times, which can reduce overall production expenses for high-precision applications. Your decision should weigh the higher initial investment against the long-term benefits of efficiency and quality in micro-molding versus the lower startup costs but potential limitations in detail and precision of conventional molding.

Latest Innovations in Micro-Molding Technologies

Latest innovations in micro-molding technologies include advancements in precision laser micromachining and high-speed injection molding that enable the creation of complex micro-scale components with enhanced accuracy and repeatability. Enhanced materials such as bio-compatible polymers and conductive composites expand application possibilities in medical devices and electronics, while real-time process monitoring systems improve quality control and reduce defects. These innovations significantly outperform conventional molding methods in producing intricate, small-scale parts with superior surface finish and dimensional stability.

Choosing the Right Molding Technique for Your Project

Micro-molding offers superior precision for producing intricate, small-scale components with tight tolerances, ideal for medical devices and microelectronics. Conventional molding suits larger parts and high-volume production runs, providing cost-effective solutions for automotive and consumer goods industries. Selecting the right molding technique depends on part size, complexity, material properties, and production volume to optimize quality and manufacturing efficiency.

Micro-molding vs conventional molding Infographic

libmatt.com

libmatt.com