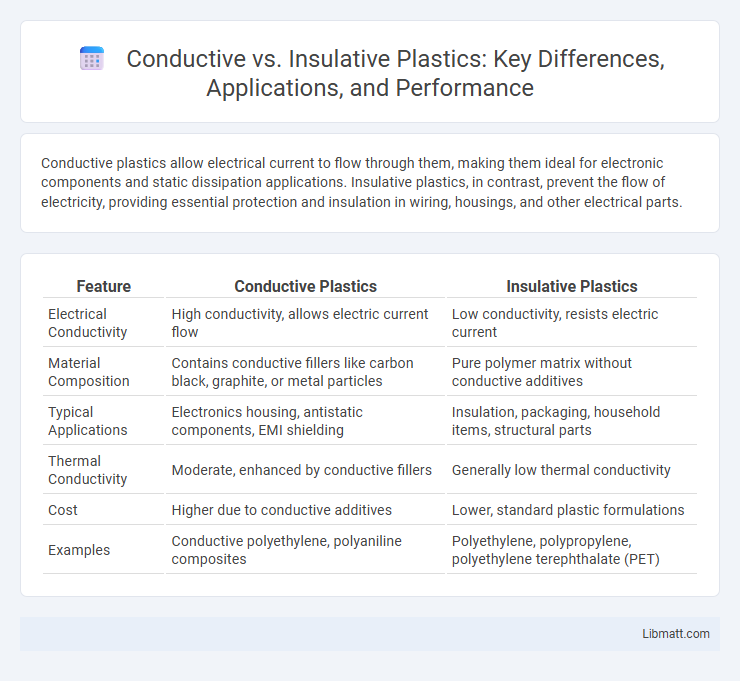

Conductive plastics allow electrical current to flow through them, making them ideal for electronic components and static dissipation applications. Insulative plastics, in contrast, prevent the flow of electricity, providing essential protection and insulation in wiring, housings, and other electrical parts.

Table of Comparison

| Feature | Conductive Plastics | Insulative Plastics |

|---|---|---|

| Electrical Conductivity | High conductivity, allows electric current flow | Low conductivity, resists electric current |

| Material Composition | Contains conductive fillers like carbon black, graphite, or metal particles | Pure polymer matrix without conductive additives |

| Typical Applications | Electronics housing, antistatic components, EMI shielding | Insulation, packaging, household items, structural parts |

| Thermal Conductivity | Moderate, enhanced by conductive fillers | Generally low thermal conductivity |

| Cost | Higher due to conductive additives | Lower, standard plastic formulations |

| Examples | Conductive polyethylene, polyaniline composites | Polyethylene, polypropylene, polyethylene terephthalate (PET) |

Introduction to Conductive and Insulative Plastics

Conductive plastics are engineered with additives like carbon black or metal particles to enable electrical conductivity, making them ideal for applications requiring static dissipation or electromagnetic interference shielding. Insulative plastics, such as polyethylene and polypropylene, inherently resist electrical current, providing effective insulation in electronic components and wiring. Understanding the distinction between conductive and insulative plastics is essential for designing safe and efficient electrical and electronic systems.

Defining Conductive Plastics: Properties and Applications

Conductive plastics are materials engineered to allow the flow of electrical current through their polymer matrix by incorporating conductive fillers such as carbon black or metal fibers. These plastics exhibit properties like electrical conductivity, mechanical flexibility, and resistance to corrosion, making them ideal for applications in electromagnetic interference (EMI) shielding, antistatic components, and flexible electronics. Understanding the unique properties of conductive plastics enables you to select the right material for advanced electronic devices and components requiring efficient electrical performance combined with lightweight and durability.

Characteristics of Insulative Plastics

Insulative plastics exhibit high electrical resistance, preventing the flow of electric current and ensuring safety in electronic applications. These materials, such as polyethylene and PVC, provide excellent thermal insulation and chemical stability, making them ideal for protective coatings and housing. Your choice of insulative plastic ensures efficient energy containment and reduces the risk of electrical hazards in devices.

Key Differences Between Conductive and Insulative Plastics

Conductive plastics contain fillers such as carbon black, metal particles, or conductive polymers that enable the flow of electric current, while insulative plastics inherently resist electrical conductivity due to their molecular structure. Conductive plastics are utilized in applications requiring static dissipation or electromagnetic interference shielding, whereas insulative plastics serve as electrical barriers in wiring, housings, and electronic components. Thermal conductivity also varies, with conductive plastics often exhibiting enhanced heat dissipation compared to the high thermal resistance of insulative plastics.

Common Materials Used in Conductive Plastics

Common materials used in conductive plastics include carbon black, graphite, and metal fillers such as silver, copper, and nickel, which enhance electrical conductivity by creating conductive pathways within the polymer matrix. Conductive polymers like polyaniline, polypyrrole, and polyacetylene are also integrated to improve charge transport properties. These materials are essential in applications requiring static dissipation, electromagnetic interference shielding, and flexible electronics.

Popular Insulative Plastics and Their Uses

Popular insulative plastics such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC) are widely used for their excellent electrical resistance and durability. Polyethylene is commonly utilized in cable insulation and electrical enclosures, while polypropylene finds applications in automotive parts and household appliances due to its chemical resistance and insulation properties. Polyvinyl chloride is preferred for wire coatings, pipes, and electrical conduit systems, providing effective protection against electrical currents and environmental factors.

Factors Influencing Plastic Conductivity

Plastic conductivity is primarily influenced by the polymer's molecular structure, including the presence of conjugated double bonds and aromatic rings that allow electron delocalization. Additives such as carbon black, metal particles, or conductive polymers can significantly enhance conductivity by forming conductive pathways within the material. Temperature and humidity also affect conductivity, as increased thermal energy can improve charge carrier mobility, while moisture may alter the dielectric properties of insulative plastics.

Advantages and Limitations of Conductive Plastics

Conductive plastics offer significant advantages such as lightweight design, corrosion resistance, and electrical conductivity suitable for antistatic coatings and electromagnetic interference shielding. These plastics enable flexible electronics and enhance device durability while reducing overall manufacturing costs. Limitations include lower conductivity compared to metals, sensitivity to environmental factors like humidity, and generally higher production costs than traditional insulative plastics.

Benefits and Drawbacks of Insulative Plastics

Insulative plastics offer excellent electrical resistance, making them ideal for applications requiring protection from electric currents and preventing short circuits. Their lightweight and corrosion-resistant properties contribute to durability and safety in electronic housings and wiring insulation. However, insulative plastics can suffer from lower thermal conductivity, which may lead to overheating issues in high-power devices.

Choosing the Right Plastic: Application-Based Guidance

Selecting the right plastic for an application hinges on its electrical properties, with conductive plastics used in electromagnetic interference shielding, static dissipation, and flexible electronics, while insulative plastics provide essential electrical isolation in wiring, circuit boards, and housings. Materials such as carbon-filled polyethylene offer tailored conductivity levels, whereas polyvinyl chloride (PVC) and polyethylene terephthalate (PET) deliver excellent insulation and durability in harsh environments. Understanding the specific electrical, thermal, and mechanical requirements of the application ensures optimal performance and longevity by matching the plastic's conductive or insulative characteristics appropriately.

Conductive vs Insulative Plastics Infographic

libmatt.com

libmatt.com