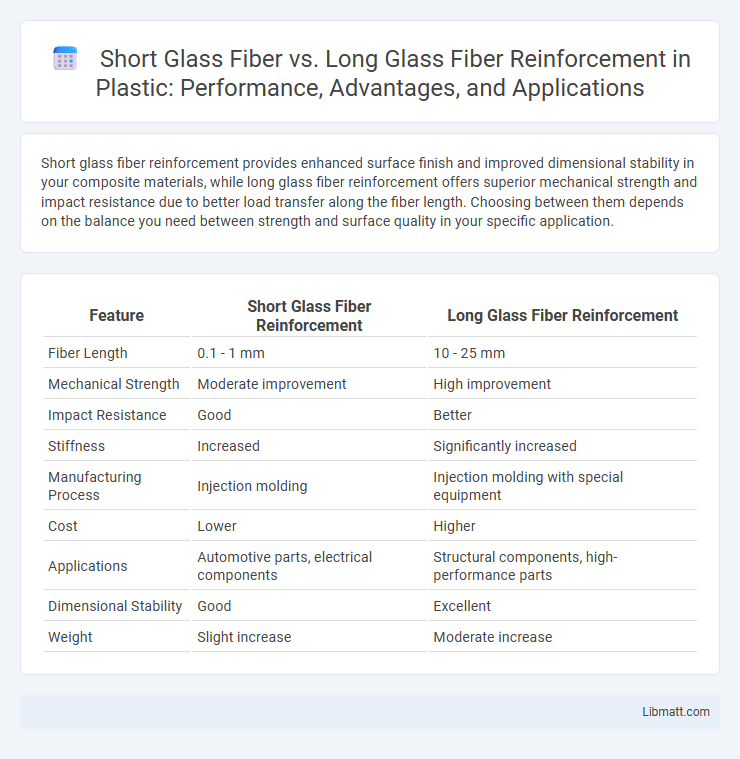

Short glass fiber reinforcement provides enhanced surface finish and improved dimensional stability in your composite materials, while long glass fiber reinforcement offers superior mechanical strength and impact resistance due to better load transfer along the fiber length. Choosing between them depends on the balance you need between strength and surface quality in your specific application.

Table of Comparison

| Feature | Short Glass Fiber Reinforcement | Long Glass Fiber Reinforcement |

|---|---|---|

| Fiber Length | 0.1 - 1 mm | 10 - 25 mm |

| Mechanical Strength | Moderate improvement | High improvement |

| Impact Resistance | Good | Better |

| Stiffness | Increased | Significantly increased |

| Manufacturing Process | Injection molding | Injection molding with special equipment |

| Cost | Lower | Higher |

| Applications | Automotive parts, electrical components | Structural components, high-performance parts |

| Dimensional Stability | Good | Excellent |

| Weight | Slight increase | Moderate increase |

Introduction to Glass Fiber Reinforcement

Glass fiber reinforcement enhances composite materials by significantly increasing tensile strength, stiffness, and impact resistance. Short glass fibers, typically less than 6 mm in length, improve toughness and dimensional stability while offering easier processing and uniform dispersion in polymer matrices. Long glass fibers, often exceeding 12 mm, provide superior mechanical performance and load-bearing capacity, making them ideal for applications requiring high strength and structural integrity.

Definition: Short Glass Fiber vs Long Glass Fiber

Short glass fiber consists of small, chopped strands typically less than 6 mm in length, used to enhance the mechanical properties of thermoplastics by improving strength and impact resistance. Long glass fiber refers to continuous or long strands, often exceeding 25 mm, which provide superior reinforcement, increased tensile strength, and enhanced stiffness in composite materials. The choice between short and long glass fibers depends on processing methods, desired mechanical performance, and application-specific requirements.

Manufacturing Processes: Short vs Long Glass Fiber

Short glass fiber reinforcement is integrated through injection molding or compression molding processes, enabling rapid production with uniform fiber dispersion and improved surface finish. Long glass fiber reinforcement requires specialized processes like pultrusion or extrusion, which align fibers lengthwise for enhanced mechanical strength and stiffness. Manufacturing with long fibers often demands precise control to prevent fiber breakage and maintain desired composite performance.

Mechanical Properties Comparison

Short glass fiber reinforcement offers improved tensile strength and impact resistance compared to unreinforced polymers, but long glass fiber reinforcement provides significantly higher flexural strength and stiffness due to better fiber alignment and stress distribution. Long glass fiber composites exhibit enhanced fatigue resistance and higher modulus of elasticity, making them suitable for structural applications requiring durability and load-bearing capacity. The selection between short and long glass fiber depends on the mechanical property priorities such as strength, stiffness, and impact resistance in the specific engineering application.

Impact on Product Durability

Short glass fiber reinforcement enhances product durability by improving impact resistance and reducing brittleness in molded parts, making them ideal for complex geometries and thin-walled components. Long glass fibers provide superior tensile strength and stiffness, significantly increasing durability in structural applications subjected to heavy loads and repeated stress. The choice between short and long glass fiber reinforcement should consider the specific mechanical performance requirements and manufacturing constraints of the end-use product.

Applications in Automotive and Industrial Sectors

Short glass fiber reinforcement offers enhanced dimensional stability and cost efficiency, making it ideal for automotive interior components, under-the-hood parts, and industrial housings where mass production and weight reduction are critical. Long glass fiber reinforcement provides superior mechanical strength and impact resistance, preferred in structural automotive parts such as bumpers, chassis components, and heavy-duty industrial machinery requiring high durability. Both fiber types improve composite materials' performance, but application choice depends on specific load requirements and manufacturing constraints within automotive and industrial sectors.

Cost Effectiveness and Material Efficiency

Short glass fiber reinforcement offers cost effectiveness through lower raw material expenses and simpler processing, making it ideal for high-volume production with moderate performance needs. Long glass fiber reinforcement provides superior material efficiency by significantly enhancing mechanical properties, allowing for lighter, stronger parts that reduce overall material usage despite higher initial costs. Choosing between the two depends on balancing budget constraints with desired strength-to-weight ratios in applications.

Processing Challenges and Solutions

Short glass fiber reinforcement presents processing challenges such as fiber breakage during mixing and uneven dispersion, leading to reduced mechanical properties and anisotropy in molded parts. Long glass fiber reinforcement, while offering superior strength and stiffness, causes difficulties in extrusion and injection molding due to fiber entanglement and increased viscosity, requiring specialized equipment and precise control of processing parameters. Solutions include optimized screw designs, controlled shear rates, and advanced compounding techniques to maintain fiber length and achieve uniform distribution in both short and long glass fiber composites.

Environmental Impact and Sustainability

Short glass fiber reinforcement typically offers lower environmental impact compared to long glass fibers due to reduced energy consumption during production and easier recyclability. Long glass fibers, while providing superior mechanical strength, often require more complex processing and generate higher waste, affecting sustainability negatively. Your choice between these materials should consider the balance between performance needs and environmental responsibilities.

Choosing the Right Fiber Reinforcement for Your Application

Short glass fiber reinforcement provides excellent surface finish and dimensional stability, ideal for complex geometries and thin-walled parts, while long glass fibers offer superior mechanical strength and impact resistance for structural components. Selecting the right fiber reinforcement depends on balancing performance requirements such as tensile strength, stiffness, and fatigue resistance with processing capabilities and cost constraints. Applications demanding lightweight and durable materials, like automotive and aerospace parts, benefit from long glass fibers, whereas consumer goods and electronic housings often utilize short glass fibers for enhanced moldability and surface quality.

Short Glass Fiber vs Long Glass Fiber Reinforcement Infographic

libmatt.com

libmatt.com