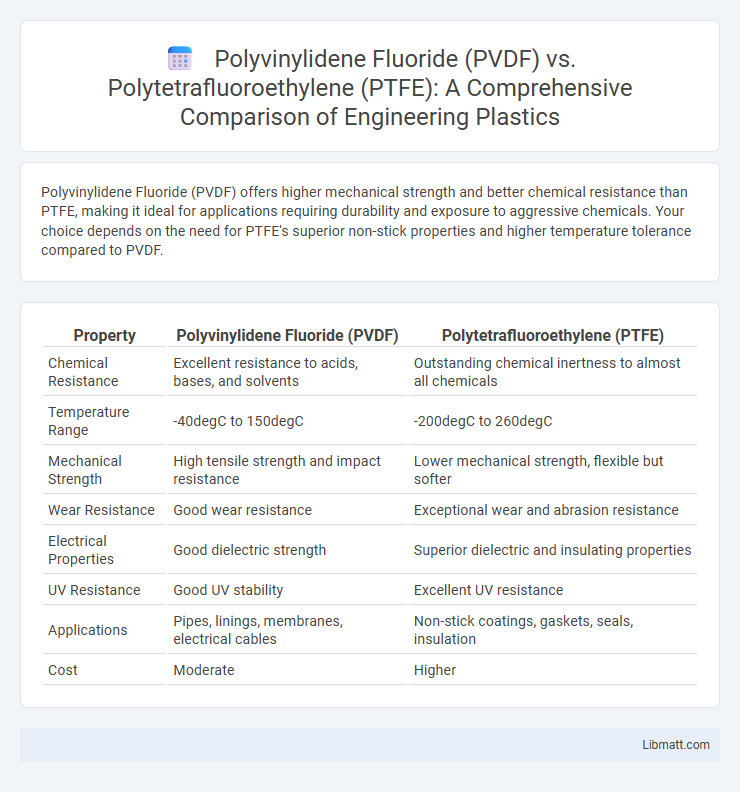

Polyvinylidene Fluoride (PVDF) offers higher mechanical strength and better chemical resistance than PTFE, making it ideal for applications requiring durability and exposure to aggressive chemicals. Your choice depends on the need for PTFE's superior non-stick properties and higher temperature tolerance compared to PVDF.

Table of Comparison

| Property | Polyvinylidene Fluoride (PVDF) | Polytetrafluoroethylene (PTFE) |

|---|---|---|

| Chemical Resistance | Excellent resistance to acids, bases, and solvents | Outstanding chemical inertness to almost all chemicals |

| Temperature Range | -40degC to 150degC | -200degC to 260degC |

| Mechanical Strength | High tensile strength and impact resistance | Lower mechanical strength, flexible but softer |

| Wear Resistance | Good wear resistance | Exceptional wear and abrasion resistance |

| Electrical Properties | Good dielectric strength | Superior dielectric and insulating properties |

| UV Resistance | Good UV stability | Excellent UV resistance |

| Applications | Pipes, linings, membranes, electrical cables | Non-stick coatings, gaskets, seals, insulation |

| Cost | Moderate | Higher |

Introduction to Polyvinylidene Fluoride (PVDF) and PTFE

Polyvinylidene Fluoride (PVDF) is a highly non-reactive and pure thermoplastic fluoropolymer known for its excellent chemical resistance, mechanical strength, and thermal stability, commonly used in piping, coatings, and membranes. PTFE (Polytetrafluoroethylene) is a fluoropolymer recognized for its superior non-stick properties, low friction, and resistance to extreme temperatures, often utilized in gasket seals, cookware, and electrical insulation. Understanding the distinct characteristics of PVDF and PTFE helps you select the optimal material for applications requiring durability and chemical inertness.

Chemical Structure and Composition

Polyvinylidene Fluoride (PVDF) features a semi-crystalline polymer structure composed of repeating vinylidene fluoride units (-CH2-CF2-), providing a balance of flexibility and chemical resistance. Polytetrafluoroethylene (PTFE), on the other hand, consists entirely of carbon-fluorine bonds in a linear chain of tetrafluoroethylene units (-CF2-CF2-), resulting in exceptional chemical inertness and thermal stability. Your choice between PVDF and PTFE depends on the required balance of mechanical properties and resistance to harsh chemical environments.

Mechanical Properties Comparison

Polyvinylidene Fluoride (PVDF) exhibits higher tensile strength, typically around 35-45 MPa, compared to Polytetrafluoroethylene (PTFE), which usually ranges between 20-30 MPa. PVDF also offers greater stiffness with a Young's modulus of approximately 400-500 MPa, whereas PTFE has a much lower modulus of about 50-150 MPa, contributing to its flexibility. Despite PTFE's superior chemical resistance and low friction, PVDF's enhanced mechanical strength and rigidity make it suitable for applications requiring durable structural performance.

Thermal Stability and Temperature Resistance

Polyvinylidene Fluoride (PVDF) exhibits excellent thermal stability with a continuous use temperature up to approximately 150degC, making it suitable for applications requiring moderate heat resistance. Polytetrafluoroethylene (PTFE) outperforms PVDF in temperature resistance, withstanding continuous exposure up to 260degC and short bursts up to 300degC due to its highly crystalline structure. The superior thermal stability of PTFE makes it ideal for high-temperature environments, whereas PVDF is preferred when chemical resistance and moderate heat tolerance are required.

Chemical Resistance and Compatibility

Polyvinylidene Fluoride (PVDF) exhibits excellent chemical resistance against acids, bases, and solvents, making it highly compatible with aggressive chemicals in industrial applications. PTFE (Polytetrafluoroethylene) surpasses PVDF in overall chemical inertness, resisting almost all chemicals including strong oxidizers and solvents at a wide range of temperatures. Both polymers offer superior compatibility for chemical processing, but PTFE is preferred in highly corrosive or high-temperature environments due to its outstanding chemical stability.

Electrical Insulation Capabilities

Polyvinylidene Fluoride (PVDF) offers excellent electrical insulation with a dielectric constant ranging between 8 to 13, making it suitable for applications requiring strong dielectric strength and low conductivity. Polytetrafluoroethylene (PTFE) excels with a low dielectric constant around 2.1 and exceptional high-frequency performance, ensuring minimal signal loss and reliable insulation in demanding electrical environments. When selecting materials, your choice depends on balancing flexibility, thermal resistance, and specific insulation requirements, where PVDF suits higher dielectric applications, and PTFE favors stability under extreme conditions.

Applications and Common Industries

Polyvinylidene Fluoride (PVDF) is extensively used in chemical processing, water treatment, and semiconductor industries due to its excellent chemical resistance, mechanical strength, and UV stability. Polytetrafluoroethylene (PTFE) finds widespread applications in non-stick cookware, aerospace, and electrical insulation industries, where its superior low friction, high thermal stability, and dielectric properties are essential. Both polymers are crucial in sealing, coating, and lining applications but differ significantly in temperature tolerance and mechanical toughness, guiding their industry-specific uses.

Processing Methods and Fabrication

Polyvinylidene Fluoride (PVDF) is processed primarily through extrusion, injection molding, and film casting due to its thermoplastic nature, allowing versatile fabrication methods suitable for complex shapes and thin films. PTFE, on the other hand, requires sintering and paste extrusion because it cannot be melted and reshaped like typical thermoplastics, limiting its processing to powder-based techniques and specialized molding processes. Your choice between PVDF and PTFE fabrication hinges on the required processing ease and application-specific form factors, with PVDF offering more conventional manufacturing flexibility.

Cost Considerations and Market Availability

Polyvinylidene Fluoride (PVDF) generally offers a more cost-effective solution compared to Polytetrafluoroethylene (PTFE) due to lower raw material costs and simpler processing techniques. PVDF markets demonstrate higher availability in industrial applications such as chemical processing and water treatment, supported by widespread manufacturing capabilities. PTFE, while more expensive, is preferred in niche markets requiring superior chemical resistance and higher temperature tolerance, impacting its price and availability.

Choosing Between PVDF and PTFE: Key Factors

When choosing between Polyvinylidene Fluoride (PVDF) and Polytetrafluoroethylene (PTFE), consider PVDF's superior mechanical strength, UV resistance, and ease of processing, making it ideal for applications requiring durability and chemical resistance. PTFE excels with exceptional chemical inertness, high-temperature tolerance, and a low friction coefficient, perfect for non-stick surfaces and extreme environments. Your choice depends on balancing performance needs like temperature range, chemical exposure, and mechanical load to optimize material suitability.

Polyvinylidene Fluoride (PVDF) vs PTFE Infographic

libmatt.com

libmatt.com