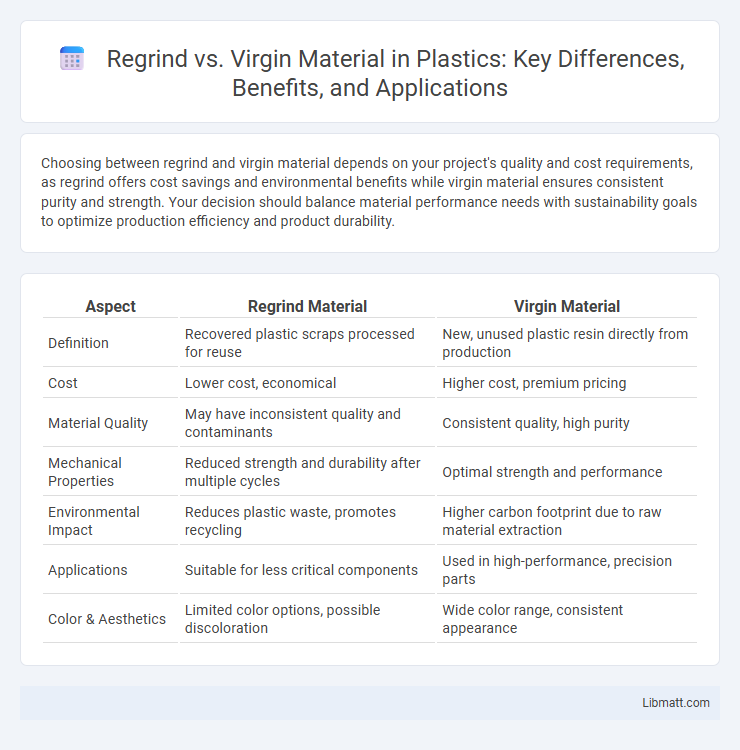

Choosing between regrind and virgin material depends on your project's quality and cost requirements, as regrind offers cost savings and environmental benefits while virgin material ensures consistent purity and strength. Your decision should balance material performance needs with sustainability goals to optimize production efficiency and product durability.

Table of Comparison

| Aspect | Regrind Material | Virgin Material |

|---|---|---|

| Definition | Recovered plastic scraps processed for reuse | New, unused plastic resin directly from production |

| Cost | Lower cost, economical | Higher cost, premium pricing |

| Material Quality | May have inconsistent quality and contaminants | Consistent quality, high purity |

| Mechanical Properties | Reduced strength and durability after multiple cycles | Optimal strength and performance |

| Environmental Impact | Reduces plastic waste, promotes recycling | Higher carbon footprint due to raw material extraction |

| Applications | Suitable for less critical components | Used in high-performance, precision parts |

| Color & Aesthetics | Limited color options, possible discoloration | Wide color range, consistent appearance |

Understanding Regrind and Virgin Material

Regrind refers to recycled plastic material that has been processed from previously manufactured products, while virgin material is newly produced resin obtained directly from petrochemical sources. Understanding the differences between regrind and virgin material is crucial for optimizing production costs and ensuring product quality in manufacturing. Your choice impacts sustainability efforts, with regrind promoting eco-friendly practices and virgin material providing consistent physical properties.

Key Differences Between Regrind and Virgin Resin

Regrind resin consists of recycled plastic material that has been melted down and reprocessed, whereas virgin resin is newly produced from raw polymer pellets without prior use. Regrind typically contains impurities and inconsistent particle sizes, affecting mechanical properties, while virgin resin offers uniform quality and superior strength for manufacturing. You can optimize production costs by blending regrind with virgin resin, but pure virgin resin is preferred for high-performance applications requiring maximum durability and clarity.

Advantages of Using Regrind Material

Regrind material offers significant cost savings by reducing the need for purchasing expensive virgin resin while maintaining a sustainable manufacturing process. Utilizing regrind enhances resource efficiency, minimizes plastic waste in landfills, and decreases environmental impact through lower carbon emissions. You benefit from improved material recycling practices that support circular economy goals without compromising product quality in many applications.

Benefits of Virgin Material in Manufacturing

Virgin material in manufacturing offers superior purity and consistent quality, ensuring enhanced product performance and reliability. Its uniform physical and chemical properties reduce defects and improve processing efficiency, leading to higher yield rates. Using virgin material supports your commitment to producing durable, high-strength components with predictable characteristics essential for critical applications.

Impact on Product Quality: Regrind vs Virgin Material

Regrind material often contains contaminants and degraded polymer chains, which can compromise the mechanical strength, surface finish, and consistency of the final product compared to virgin material. Virgin material provides superior purity and uniform molecular structure, enhancing product durability, appearance, and performance in critical applications. Careful blending and processing of regrind can mitigate quality issues but rarely match the reliability and aesthetic standards achievable with 100% virgin resin.

Cost Comparison: Regrind vs Virgin Material

Regrind material offers significant cost savings compared to virgin material, often reducing raw material expenses by up to 30-50% depending on the industry and application. Virgin materials provide consistent quality but come at a higher price due to processing and sourcing costs, which can impact your overall production budget. Selecting regrind over virgin can optimize your manufacturing costs without compromising product performance when quality control measures are in place.

Environmental Sustainability Considerations

Regrind material significantly reduces environmental impact by lowering waste generation and conserving natural resources compared to virgin material, which requires fresh raw inputs. Utilizing regrind in manufacturing processes decreases energy consumption and greenhouse gas emissions associated with raw material extraction and production. Incorporating higher percentages of regrind supports circular economy goals by promoting material reuse and minimizing landfill contributions.

Common Applications for Regrind and Virgin Materials

Regrind materials are commonly used in applications such as injection molding, extrusion, and rotational molding where cost efficiency and sustainability are prioritized, including producing non-critical parts, pallets, and automotive components. Virgin materials dominate in applications requiring high mechanical strength, clarity, and purity, such as medical devices, food packaging, and high-performance automotive parts. Choosing between regrind and virgin materials depends on the balance between product quality requirements and manufacturing cost constraints.

Challenges and Limitations of Regrind Usage

Regrind material faces challenges such as inconsistent melt flow and potential contamination, which can affect the final product's mechanical properties and visual quality. Its limited ability to maintain the strength and clarity of virgin materials restricts its use in high-performance or aesthetic applications. Your manufacturing process may require careful blending ratios and quality control measures to mitigate these limitations and ensure product consistency.

Choosing the Right Material: Factors to Consider

Selecting between regrind and virgin material depends on factors such as product quality requirements, cost constraints, and environmental impact. Virgin material offers consistent purity and strength, ideal for high-performance applications, while regrind provides a cost-effective, sustainable option suitable for less critical parts. Your choice should balance production standards with sustainability goals and budget considerations to ensure optimal results.

Regrind vs Virgin Material Infographic

libmatt.com

libmatt.com