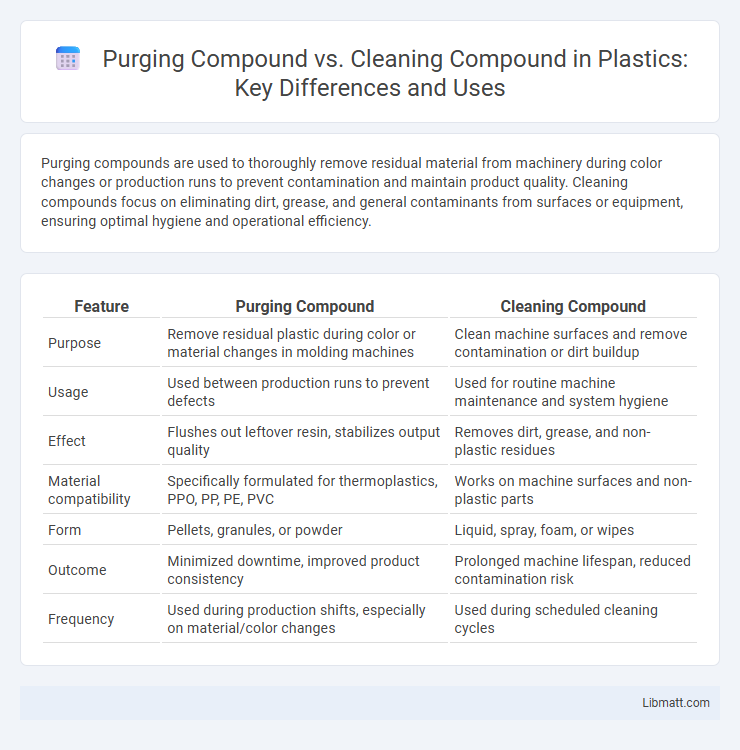

Purging compounds are used to thoroughly remove residual material from machinery during color changes or production runs to prevent contamination and maintain product quality. Cleaning compounds focus on eliminating dirt, grease, and general contaminants from surfaces or equipment, ensuring optimal hygiene and operational efficiency.

Table of Comparison

| Feature | Purging Compound | Cleaning Compound |

|---|---|---|

| Purpose | Remove residual plastic during color or material changes in molding machines | Clean machine surfaces and remove contamination or dirt buildup |

| Usage | Used between production runs to prevent defects | Used for routine machine maintenance and system hygiene |

| Effect | Flushes out leftover resin, stabilizes output quality | Removes dirt, grease, and non-plastic residues |

| Material compatibility | Specifically formulated for thermoplastics, PPO, PP, PE, PVC | Works on machine surfaces and non-plastic parts |

| Form | Pellets, granules, or powder | Liquid, spray, foam, or wipes |

| Outcome | Minimized downtime, improved product consistency | Prolonged machine lifespan, reduced contamination risk |

| Frequency | Used during production shifts, especially on material/color changes | Used during scheduled cleaning cycles |

Introduction to Purging Compounds and Cleaning Compounds

Purging compounds are specialized materials designed to remove residual polymers and contaminants from extrusion or injection molding machines, ensuring a seamless color or resin changeover. Cleaning compounds, by comparison, focus on eliminating surface impurities and buildup within manufacturing equipment to maintain optimal operational efficiency. Understanding the distinct formulation and application benefits of purging versus cleaning compounds is essential for minimizing downtime and enhancing product quality in plastic processing industries.

Defining Purging Compounds

Purging compounds are specialized materials designed to efficiently remove residual polymers from injection molding and extrusion machines during color or resin changes. They work by softening and dislodging melted plastics adhering to machine barrels, screws, and nozzles, ensuring minimal contamination and downtime. Your production process benefits from purging compounds by enhancing product quality and reducing waste compared to standard cleaning compounds.

Defining Cleaning Compounds

Cleaning compounds are substances specifically formulated to remove contaminants, residues, and buildup from equipment surfaces, ensuring optimal performance and preventing cross-contamination in manufacturing processes. Unlike purging compounds, which are designed to clear out residual material between color or material changes, cleaning compounds focus on maintaining cleanliness and prolonging machinery lifespan. Using the right cleaning compound for your equipment enhances operational efficiency and reduces downtime.

Key Differences Between Purging and Cleaning Compounds

Purging compounds are formulated to remove residual materials and contaminants from injection molding or extrusion machines, ensuring minimal color change and product defects during material switches. Cleaning compounds primarily focus on eliminating surface residues, buildup, and oxide layers without necessarily addressing deep-seated contamination within the machinery. The key difference lies in purging compounds targeting internal cleaning for material integrity and continuity, whereas cleaning compounds concentrate on external maintenance and surface cleanliness.

Applications of Purging Compounds in Manufacturing

Purging compounds are essential in manufacturing for efficiently clearing residual materials from injection molding and extrusion machines, minimizing color contamination and reducing downtime during product changes. These compounds improve production quality by ensuring cleaner machine barrels and screw surfaces, which is critical for maintaining consistent output and preventing defects. Your use of purging compounds enhances operational efficiency and helps maintain strict quality control in high-volume manufacturing environments.

Applications of Cleaning Compounds in Industry

Cleaning compounds play a vital role in industries by removing contaminants such as oils, grease, and residues from machinery, production lines, and surfaces to maintain optimal operation and product quality. They are essential in sectors like automotive, manufacturing, pharmaceuticals, and electronics for cleaning parts and equipment before assembly or further processing. You can rely on cleaning compounds to ensure hygiene standards, prevent cross-contamination, and extend the lifespan of industrial components.

Advantages and Disadvantages of Purging Compounds

Purging compounds offer the advantage of effectively removing residual material from injection molding machines, reducing color contamination and minimizing downtime during material changes. They improve product quality by preventing defects such as streaks or color mixing but can be more expensive and require specific handling compared to standard cleaning compounds. However, improper use of purging compounds may lead to equipment wear or incomplete residue removal, making correct application crucial for optimal performance.

Pros and Cons of Cleaning Compounds

Cleaning compounds effectively remove contaminants and residues from manufacturing equipment, ensuring optimal performance and product quality. However, they may cause equipment wear or require extensive cleaning time compared to purging compounds, which are specifically designed to minimize downtime and prevent cross-contamination. Your choice depends on balancing thorough cleaning needs against processing efficiency and equipment longevity.

Factors to Consider When Choosing Between Purging and Cleaning Compounds

Selecting between purging compounds and cleaning compounds depends on factors such as the type of machinery, the nature of contaminants, and the frequency of color or material changes. Purging compounds are typically used for thorough removal of residual polymers during material or color changes in injection molding and extrusion processes, while cleaning compounds focus on surface dirt and minor deposits. Consider the compatibility with machine components, downtime requirements, and the cleaning effectiveness needed to optimize production efficiency.

Conclusion: Selecting the Right Compound for Optimal Performance

Choosing between purging compound and cleaning compound depends on your specific manufacturing process and equipment requirements. Purging compounds are designed to efficiently remove residual plastic during color or material changes, minimizing downtime and preventing contamination. For optimal performance, selecting the right compound ensures your machinery runs smoothly while maintaining product quality and reducing maintenance costs.

Purging compound vs cleaning compound Infographic

libmatt.com

libmatt.com