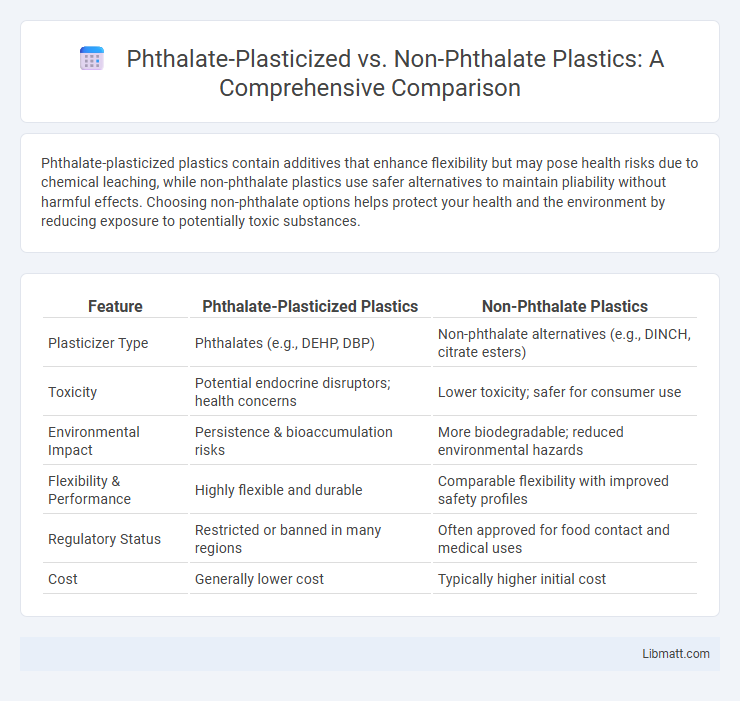

Phthalate-plasticized plastics contain additives that enhance flexibility but may pose health risks due to chemical leaching, while non-phthalate plastics use safer alternatives to maintain pliability without harmful effects. Choosing non-phthalate options helps protect your health and the environment by reducing exposure to potentially toxic substances.

Table of Comparison

| Feature | Phthalate-Plasticized Plastics | Non-Phthalate Plastics |

|---|---|---|

| Plasticizer Type | Phthalates (e.g., DEHP, DBP) | Non-phthalate alternatives (e.g., DINCH, citrate esters) |

| Toxicity | Potential endocrine disruptors; health concerns | Lower toxicity; safer for consumer use |

| Environmental Impact | Persistence & bioaccumulation risks | More biodegradable; reduced environmental hazards |

| Flexibility & Performance | Highly flexible and durable | Comparable flexibility with improved safety profiles |

| Regulatory Status | Restricted or banned in many regions | Often approved for food contact and medical uses |

| Cost | Generally lower cost | Typically higher initial cost |

Introduction to Plasticizers in Plastics

Plasticizers are additives used to enhance the flexibility, durability, and workability of plastics by increasing their softness and reducing brittleness. Phthalate-plasticized plastics contain phthalates, a common class of plasticizers known for their effectiveness but also associated with health and environmental concerns. Non-phthalate plastics use alternative plasticizers that offer safer, more sustainable solutions without compromising the performance and flexibility of your products.

What Are Phthalates?

Phthalates are a group of chemical compounds primarily used as plasticizers to increase the flexibility, transparency, and durability of plastics, especially polyvinyl chloride (PVC). These substances chemically bond with polymer chains, enhancing plastic softness and workability in products such as toys, packaging, and medical devices. Concerns over health and environmental impacts have driven the development and use of non-phthalate plasticizers as safer alternatives in various industrial applications.

Non-Phthalate Plasticizers: Types and Benefits

Non-phthalate plasticizers include citrate esters, adipates, and trimellitates, offering safer alternatives to traditional phthalate-based compounds in flexible plastics. These plasticizers improve flexibility, durability, and low-temperature performance while reducing health risks such as endocrine disruption and toxicity associated with phthalates. Non-phthalate plasticizers are widely used in medical devices, food packaging, and children's toys, where regulatory compliance and consumer safety are critical.

Comparing Chemical Structures

Phthalate-plasticized plastics incorporate phthalate esters, featuring aromatic rings and ester functional groups that provide flexibility by interacting with polymer chains. Non-phthalate plastics use alternative plasticizers such as adipates or citrates, which possess different chemical backbones, like aliphatic chains or citrate esters, leading to varied compatibility and flexibility profiles. These structural differences influence the plasticizers' migration rates, toxicity profiles, and overall performance in polymer matrices.

Performance Differences: Phthalate vs Non-Phthalate Plastics

Phthalate-plasticized plastics are known for their superior flexibility, durability, and cost-effectiveness, making them ideal for applications requiring soft, pliable materials such as medical devices and flexible tubing. Non-phthalate plastics, while often less flexible, offer enhanced safety profiles with reduced toxicity and better environmental sustainability, gaining favor in consumer goods and children's products. Performance-wise, non-phthalate alternatives may exhibit increased brittleness and higher production costs but meet stringent regulatory standards for health and safety.

Health and Safety Concerns of Phthalates

Phthalate-plasticized plastics are widely used for their flexibility but raise significant health and safety concerns due to their endocrine-disrupting properties linked to reproductive toxicity and developmental issues. Studies show phthalate exposure can lead to hormonal imbalances and increase the risk of asthma, allergies, and neurodevelopmental disorders, particularly in children. Non-phthalate plastics offer safer alternatives, reducing the risks associated with phthalates by utilizing plasticizers that do not leach harmful chemicals, thereby improving product safety for consumers.

Environmental Impact: Biodegradability and Toxicity

Phthalate-plasticized plastics exhibit limited biodegradability and release toxic compounds that can harm aquatic ecosystems and disrupt endocrine systems in wildlife and humans. Non-phthalate plastics, often designed with bio-based or alternative plasticizers, tend to improve biodegradability and reduce toxicity, thereby minimizing environmental contamination and health risks. Lifecycle assessments frequently show that non-phthalate plastics offer a more sustainable option by decreasing persistent organic pollutants and supporting safer disposal processes.

Regulatory Policies and Global Restrictions

Phthalate-plasticized plastics face strict regulatory policies across the European Union, United States, and several Asian countries due to concerns over toxicity and endocrine disruption. Non-phthalate plastics are increasingly favored in global markets as safer alternatives that comply with REACH regulations, the U.S. Consumer Product Safety Improvement Act, and various national restrictions. Your sourcing decisions should prioritize non-phthalate materials to ensure compliance with evolving international safety standards and avoid regulatory penalties.

Industry Applications: Where Each Type Is Used

Phthalate-plasticized plastics are predominantly utilized in flexible applications such as medical devices, wire insulation, and automotive interiors, where softness and durability are crucial. Non-phthalate plastics find extensive use in food packaging, toys, and healthcare products due to increasing regulatory restrictions on phthalates and rising consumer demand for safer alternatives. Industries like construction and electronics also adopt non-phthalate plasticizers to comply with environmental standards while maintaining performance.

Future Trends in Plasticizer Alternatives

Future trends in plasticizer alternatives emphasize the rise of non-phthalate plasticizers due to increasing regulatory restrictions and health concerns associated with phthalate-plasticized plastics. Biobased and renewable-source plasticizers such as citrates, adipates, and sebacates are gaining traction for their lower toxicity and improved environmental profiles. Advances in polymer chemistry are enabling enhanced compatibility and performance of non-phthalate plasticizers, driving innovation in safer and more sustainable plastic products.

Phthalate-Plasticized vs Non-Phthalate Plastics Infographic

libmatt.com

libmatt.com