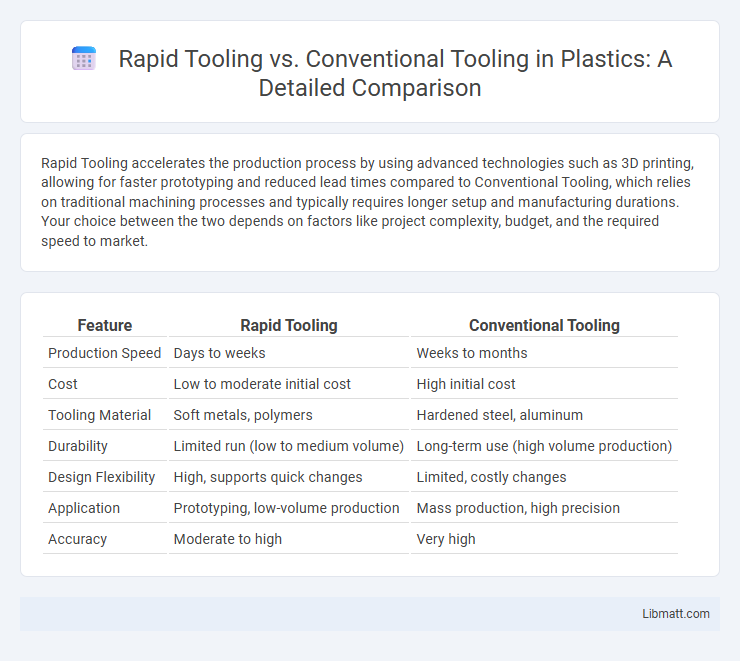

Rapid Tooling accelerates the production process by using advanced technologies such as 3D printing, allowing for faster prototyping and reduced lead times compared to Conventional Tooling, which relies on traditional machining processes and typically requires longer setup and manufacturing durations. Your choice between the two depends on factors like project complexity, budget, and the required speed to market.

Table of Comparison

| Feature | Rapid Tooling | Conventional Tooling |

|---|---|---|

| Production Speed | Days to weeks | Weeks to months |

| Cost | Low to moderate initial cost | High initial cost |

| Tooling Material | Soft metals, polymers | Hardened steel, aluminum |

| Durability | Limited run (low to medium volume) | Long-term use (high volume production) |

| Design Flexibility | High, supports quick changes | Limited, costly changes |

| Application | Prototyping, low-volume production | Mass production, high precision |

| Accuracy | Moderate to high | Very high |

Introduction to Rapid Tooling and Conventional Tooling

Rapid tooling leverages additive manufacturing and advanced machining techniques to create molds and dies swiftly, significantly reducing lead time compared to conventional tooling. Conventional tooling relies on traditional subtractive processes such as CNC machining and casting, prioritizing high durability and precision for large production runs. Rapid tooling suits prototyping and short-run production, whereas conventional tooling remains ideal for mass manufacturing demanding consistent quality.

Defining Rapid Tooling

Rapid Tooling refers to the process of creating molds and dies quickly using additive manufacturing or other fast fabrication techniques, significantly reducing production lead times compared to Conventional Tooling. This method enables rapid prototyping and short-run production, making it ideal for testing designs and accelerating time-to-market. You can leverage Rapid Tooling to enhance flexibility and cost-efficiency in product development cycles.

Understanding Conventional Tooling

Conventional tooling involves machining molds or dies using traditional manufacturing methods such as CNC milling and EDM, typically crafted from hardened steel or aluminum. This approach ensures high precision, durability, and suitability for large production runs but requires significant lead times and higher upfront costs. Conventional tooling remains essential for industries demanding robust, repetitive production capabilities with consistent part quality.

Key Differences Between Rapid and Conventional Tooling

Rapid Tooling uses additive manufacturing and 3D printing to create molds quickly, significantly reducing lead times compared to Conventional Tooling's subtractive processes like CNC machining. Material flexibility and cost efficiency are major advantages of Rapid Tooling, making it ideal for low-volume, prototype, or custom production, whereas Conventional Tooling offers durability and precision suited for high-volume manufacturing. Your choice depends on the balance between speed, cost, and production scale required for your project.

Speed of Production: A Comparative Analysis

Rapid tooling significantly reduces production lead times by using additive manufacturing and direct digital processes, enabling faster iteration and prototyping compared to conventional tooling's time-intensive machining and molding methods. The speed advantage in rapid tooling accelerates product development cycles, allowing your designs to reach market readiness much sooner. Conventional tooling remains advantageous for high-volume production due to established processes but cannot match the swift turnaround provided by rapid tooling techniques.

Cost Implications and Investment Factors

Rapid tooling significantly reduces initial investment costs compared to conventional tooling by utilizing additive manufacturing and quicker prototyping methods, which lower labor and material expenses. Conventional tooling demands higher upfront capital due to expensive machining, longer production cycles, and extensive material wastage, making it costlier for short-run production. Investment factors favor rapid tooling for agile product development and low-volume runs, while conventional tooling is more economical long-term for high-volume manufacturing due to its durability and repeatability.

Material Choices and Application Suitability

Rapid tooling employs advanced materials such as photopolymers and aluminum alloys, enabling quick production cycles ideal for prototype and small-batch manufacturing. Conventional tooling uses durable materials like steel and hardened tool steels, suited for high-volume, long-term production runs requiring consistent precision. Understanding your application's volume and material demands helps determine if rapid tooling's flexibility or conventional tooling's durability better meets your manufacturing goals.

Accuracy, Quality, and Tolerances

Rapid tooling offers enhanced accuracy by utilizing advanced additive manufacturing techniques, enabling the production of complex geometries with tighter tolerances compared to conventional tooling. The quality of rapid tooling is often superior for prototyping and low-volume production due to its ability to quickly iterate designs without extensive tooling wear. Conventional tooling excels in maintaining consistent tolerances for high-volume production, but may require longer lead times and higher costs to achieve the same level of precision found in rapid tooling processes.

Selecting the Right Tooling Method for Your Project

Selecting the right tooling method for your project involves evaluating factors such as production volume, cost constraints, and time-to-market requirements. Rapid tooling offers faster turnaround and lower upfront costs suitable for prototyping and small batches, while conventional tooling provides higher durability and precision optimal for large-scale manufacturing. Assessing project specifications and lifecycle needs ensures the chosen method aligns with efficiency and quality goals.

Future Trends in Tooling Technologies

Future trends in tooling technologies emphasize the integration of rapid tooling with advanced 3D printing materials, enabling faster production cycles and reducing lead times compared to conventional tooling methods. Industry 4.0 and smart manufacturing systems are driving the adoption of digital twins and AI-based process optimizations to enhance precision and tool longevity. Sustainable tooling solutions using eco-friendly materials and energy-efficient production processes are becoming critical to meet growing environmental regulations and reduce operational costs.

Rapid Tooling vs Conventional Tooling Infographic

libmatt.com

libmatt.com