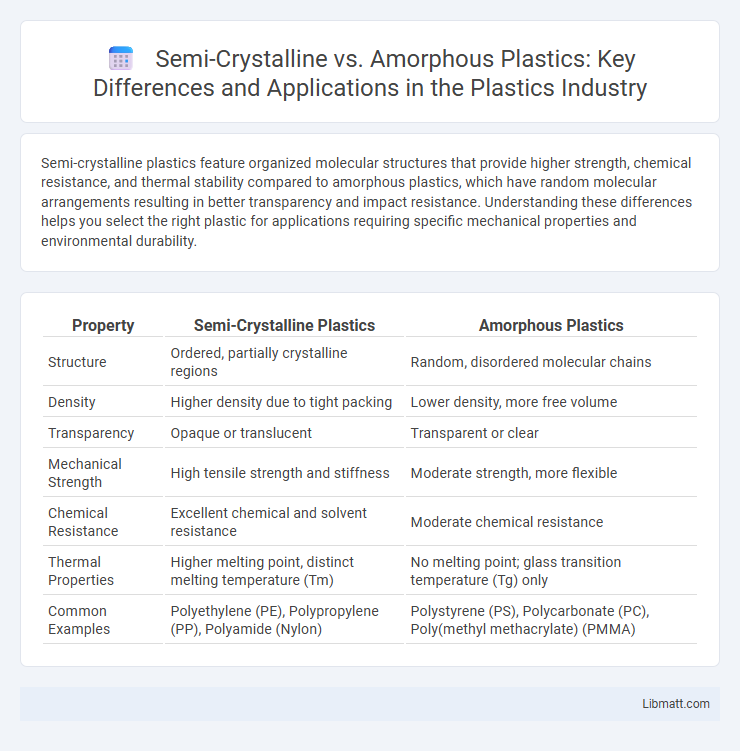

Semi-crystalline plastics feature organized molecular structures that provide higher strength, chemical resistance, and thermal stability compared to amorphous plastics, which have random molecular arrangements resulting in better transparency and impact resistance. Understanding these differences helps you select the right plastic for applications requiring specific mechanical properties and environmental durability.

Table of Comparison

| Property | Semi-Crystalline Plastics | Amorphous Plastics |

|---|---|---|

| Structure | Ordered, partially crystalline regions | Random, disordered molecular chains |

| Density | Higher density due to tight packing | Lower density, more free volume |

| Transparency | Opaque or translucent | Transparent or clear |

| Mechanical Strength | High tensile strength and stiffness | Moderate strength, more flexible |

| Chemical Resistance | Excellent chemical and solvent resistance | Moderate chemical resistance |

| Thermal Properties | Higher melting point, distinct melting temperature (Tm) | No melting point; glass transition temperature (Tg) only |

| Common Examples | Polyethylene (PE), Polypropylene (PP), Polyamide (Nylon) | Polystyrene (PS), Polycarbonate (PC), Poly(methyl methacrylate) (PMMA) |

Introduction to Plastics: Semi-Crystalline vs Amorphous

Semi-crystalline plastics, such as polyethylene and polypropylene, feature a structured molecular arrangement that provides higher strength, chemical resistance, and translucency. Amorphous plastics like polystyrene and polycarbonate lack this ordered structure, resulting in greater transparency and impact resistance but lower chemical resistance and rigidity. Understanding the differences in molecular structure helps optimize material selection for applications requiring specific mechanical properties and environmental durability.

Molecular Structure Differences

Semi-crystalline plastics have tightly packed polymer chains organized in ordered, crystalline regions, providing higher density and mechanical strength. Amorphous plastics feature randomly arranged polymer chains lacking long-range order, resulting in transparency and better impact resistance. Understanding these molecular structure differences helps you select the right plastic for specific applications based on durability and flexibility needs.

Thermal Properties Comparison

Semi-crystalline plastics exhibit higher melting points and greater thermal resistance due to their ordered molecular structure, making them ideal for high-temperature applications. Amorphous plastics have lower glass transition temperatures and tend to soften gradually rather than melt sharply, offering better dimensional stability but less heat tolerance. Understanding these thermal properties helps you select the appropriate material based on temperature requirements and performance needs.

Mechanical Strength and Flexibility

Semi-crystalline plastics exhibit higher mechanical strength due to their ordered molecular structure, which provides excellent resistance to stress and impact. Amorphous plastics offer superior flexibility and impact resistance by virtue of their random molecular arrangement, allowing them to absorb energy without fracturing. The crystallinity level directly influences the balance between stiffness and ductility in polymer materials.

Transparency and Optical Characteristics

Semi-crystalline plastics exhibit lower transparency due to their ordered molecular regions that scatter light, resulting in a cloudy or opaque appearance. Amorphous plastics possess random molecular structures that allow higher light transmission, providing clear and glass-like optical characteristics. Your choice between these plastics affects the visibility and aesthetic quality of your product, especially if clarity is a critical requirement.

Processing Techniques and Applications

Semi-crystalline plastics, such as polyethylene and polypropylene, undergo processing techniques like injection molding and extrusion that leverage their distinct melting points for enhanced strength and chemical resistance in applications like automotive parts and containers. Amorphous plastics, including polystyrene and polycarbonate, are ideal for processes like thermoforming and blow molding due to their uniform melt behavior, making them suitable for optical lenses, medical devices, and packaging. Understanding these material characteristics helps you select the right plastic type to optimize manufacturing efficiency and product performance.

Chemical Resistance and Durability

Semi-crystalline plastics such as polyethylene and polypropylene exhibit superior chemical resistance due to their tightly packed molecular structure, making them highly durable in harsh environments. Amorphous plastics like polystyrene and polycarbonate have less chemical resistance because of their random molecular arrangement, leading to greater susceptibility to chemical attack and lower overall durability. The higher crystallinity of semi-crystalline plastics enhances their mechanical strength and resistance to solvents, acids, and bases compared to amorphous counterparts.

Cost Implications and Availability

Semi-crystalline plastics often have higher production costs due to complex processing requirements but provide greater durability and chemical resistance, impacting your long-term expenses favorably. Amorphous plastics typically cost less upfront and are widely available, making them suitable for budget-sensitive applications with faster turnaround times. Availability of semi-crystalline materials can be more limited compared to the extensive range of amorphous plastics offered by numerous suppliers worldwide.

Common Examples of Each Type

Semi-crystalline plastics include polyethylene (PE), polypropylene (PP), and polyamide (nylon), known for their high strength and chemical resistance. Amorphous plastics such as polystyrene (PS), polycarbonate (PC), and acrylic (PMMA) exhibit clarity, impact resistance, and dimensional stability. These examples highlight the distinct molecular structures that dictate their respective mechanical properties and applications.

Selecting the Right Plastic for Your Needs

Selecting the right plastic involves understanding the key differences between semi-crystalline and amorphous plastics, as semi-crystalline plastics offer higher chemical resistance, greater tensile strength, and better thermal stability, making them ideal for automotive and industrial applications. Amorphous plastics provide superior clarity, easier processing, and better impact resistance, often preferred for packaging, optical lenses, and consumer goods. Evaluating specific performance requirements such as temperature range, mechanical stress, and environmental exposure ensures optimal material choice for each application.

Semi-Crystalline vs Amorphous Plastics Infographic

libmatt.com

libmatt.com