Overmolding involves molding a soft or flexible material over a rigid substrate to create a single part with enhanced functionality or grip, while insert molding embeds pre-formed components into a mold and then injects plastic around them to form a durable assembly. Your choice between overmolding and insert molding depends on factors like desired product complexity, material compatibility, and manufacturing cost efficiency.

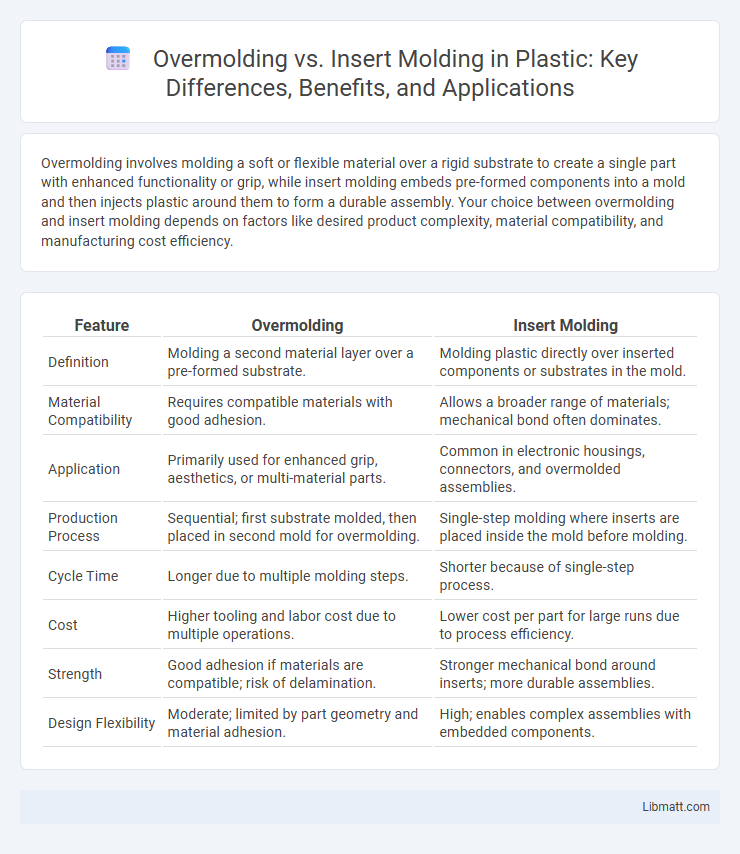

Table of Comparison

| Feature | Overmolding | Insert Molding |

|---|---|---|

| Definition | Molding a second material layer over a pre-formed substrate. | Molding plastic directly over inserted components or substrates in the mold. |

| Material Compatibility | Requires compatible materials with good adhesion. | Allows a broader range of materials; mechanical bond often dominates. |

| Application | Primarily used for enhanced grip, aesthetics, or multi-material parts. | Common in electronic housings, connectors, and overmolded assemblies. |

| Production Process | Sequential; first substrate molded, then placed in second mold for overmolding. | Single-step molding where inserts are placed inside the mold before molding. |

| Cycle Time | Longer due to multiple molding steps. | Shorter because of single-step process. |

| Cost | Higher tooling and labor cost due to multiple operations. | Lower cost per part for large runs due to process efficiency. |

| Strength | Good adhesion if materials are compatible; risk of delamination. | Stronger mechanical bond around inserts; more durable assemblies. |

| Design Flexibility | Moderate; limited by part geometry and material adhesion. | High; enables complex assemblies with embedded components. |

Introduction to Overmolding and Insert Molding

Overmolding and insert molding are advanced manufacturing processes used to combine multiple materials into a single component, enhancing product functionality and aesthetics. Overmolding involves molding a soft or flexible material over a rigid substrate, commonly used for ergonomic grips or sealing applications. Insert molding integrates pre-formed components, such as metal or plastic inserts, into a mold before injecting the base material, creating a strong bond and precise alignment essential for complex assemblies.

Core Definitions: Overmolding vs Insert Molding

Overmolding is a manufacturing process where a single part is created by molding one material over or around a different substrate, often enhancing grip, aesthetics, or functionality. Insert molding involves embedding a pre-formed component, such as metal or plastic inserts, into a mold and then injecting molten material around it to form a single, unified part. Both techniques are widely used in industries like automotive, electronics, and medical devices to combine materials with varying properties in a precise, efficient manner.

Key Differences Between Overmolding and Insert Molding

Overmolding involves molding a second material over a fully formed substrate to enhance functionality and aesthetics, whereas insert molding encapsulates a pre-placed insert within the molded material to create a single part. Overmolding typically uses flexible materials like rubber over rigid plastics, while insert molding combines metal or plastic inserts with the molded polymer. The key differences lie in their applications, material compatibility, and process integration, impacting cost, strength, and design complexity.

Materials Used in Overmolding and Insert Molding

Overmolding commonly uses thermoplastic materials such as TPU, TPE, and silicone to provide a soft-touch finish or enhanced grip over a rigid substrate. Insert molding typically involves combining rigid materials like metals or hard plastics with compatible thermoplastics such as nylon or polypropylene to create strong, integrated components. Your choice between overmolding and insert molding depends on the desired material properties and application requirements.

Process Steps: Overmolding Explained

Overmolding involves a two-step injection molding process where a base substrate is molded first, followed by molding a second material over or around it to create a single final part. The primary process steps include preparing the substrate, placing it into the mold cavity for the secondary material injection, and cooling to solidify the combined materials. This technique enhances part functionality and aesthetics by integrating multiple materials with different properties in one component.

Process Steps: Insert Molding Explained

Insert molding involves placing a pre-made component, such as metal or plastic inserts, into a mold before injecting molten material around it, creating a single cohesive part. The process begins with positioning the insert precisely in the mold cavity, followed by injecting the molten polymer to encapsulate the insert, ensuring strong adhesion and structural integrity. Your product benefits from enhanced durability and streamlined assembly since the insert molding integrates multiple components into one molded part, reducing manufacturing steps and improving performance.

Advantages and Disadvantages of Overmolding

Overmolding offers enhanced design flexibility by allowing multiple materials to be combined into a single, seamless part, improving grip, aesthetics, and shock absorption. Its advantages include reduced assembly time and cost savings, while disadvantages involve longer production cycles and higher tooling expenses compared to traditional molding. You should consider overmolding when your product requires intricate multi-material integration, but be aware of the potential complexity in mold design and material compatibility challenges.

Advantages and Disadvantages of Insert Molding

Insert molding offers advantages such as strong mechanical bonds between the insert and the molded material, enhanced durability, and improved design flexibility by integrating multiple components into a single part. However, disadvantages include higher tooling costs, longer production cycle times, and potential limitations in material compatibility, which can impact manufacturing efficiency and part performance. Your choice of insert molding should consider these factors relative to product requirements and cost constraints.

Typical Applications and Industries

Overmolding is commonly used in consumer electronics, automotive components, and medical devices to enhance grip, protect against moisture, and improve aesthetics, while insert molding is prevalent in electronics, automotive, and aerospace industries for embedding metal inserts or fasteners directly into plastic parts to increase mechanical strength. Overmolding suits applications requiring soft-touch surfaces and ergonomic features, such as tool handles and wearable devices. Insert molding excels in manufacturing precision components like electrical connectors and engine parts needing robust mechanical integration.

Choosing Between Overmolding and Insert Molding: Which is Right for You?

Choosing between overmolding and insert molding depends on the complexity of the design, material compatibility, and production volume. Overmolding is ideal for creating multi-material parts with enhanced ergonomics or aesthetics by molding a soft material over a rigid substrate. Insert molding integrates pre-formed components, like metal or electronic inserts, directly into plastic parts for improved strength and functionality in high-precision applications.

Overmolding vs Insert Molding Infographic

libmatt.com

libmatt.com