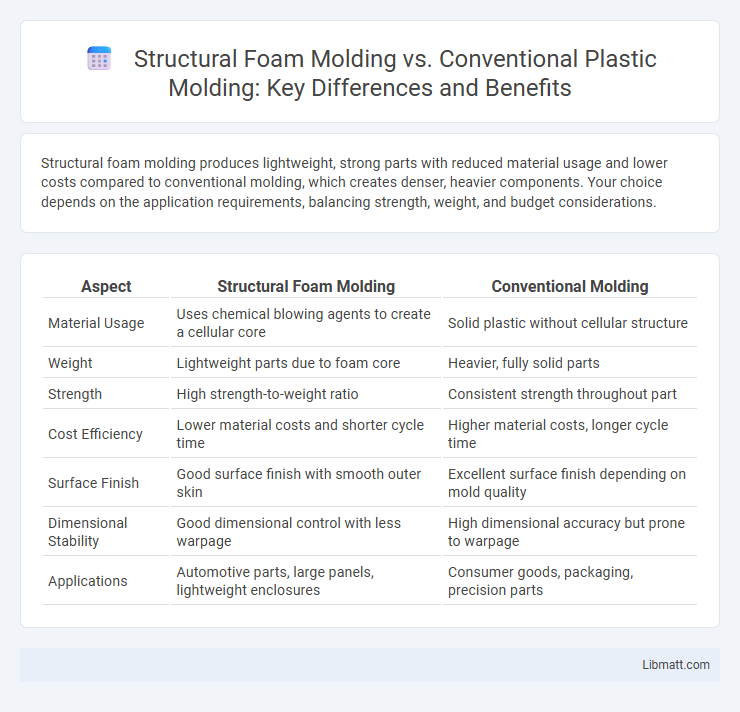

Structural foam molding produces lightweight, strong parts with reduced material usage and lower costs compared to conventional molding, which creates denser, heavier components. Your choice depends on the application requirements, balancing strength, weight, and budget considerations.

Table of Comparison

| Aspect | Structural Foam Molding | Conventional Molding |

|---|---|---|

| Material Usage | Uses chemical blowing agents to create a cellular core | Solid plastic without cellular structure |

| Weight | Lightweight parts due to foam core | Heavier, fully solid parts |

| Strength | High strength-to-weight ratio | Consistent strength throughout part |

| Cost Efficiency | Lower material costs and shorter cycle time | Higher material costs, longer cycle time |

| Surface Finish | Good surface finish with smooth outer skin | Excellent surface finish depending on mold quality |

| Dimensional Stability | Good dimensional control with less warpage | High dimensional accuracy but prone to warpage |

| Applications | Automotive parts, large panels, lightweight enclosures | Consumer goods, packaging, precision parts |

Introduction to Structural Foam Molding

Structural foam molding uses a chemical blowing agent to create a lightweight, cellular core within plastic parts, significantly reducing material usage while maintaining strength. Unlike conventional molding, which produces solid, denser components, this process offers improved dimensional stability and reduced warping for larger parts. You can achieve cost savings and enhanced mechanical properties with structural foam molding, making it ideal for automotive, appliance, and industrial applications.

Overview of Conventional Molding Techniques

Conventional molding techniques, such as injection molding and compression molding, utilize solid thermoplastic or thermosetting materials heated and forced into molds to form parts with consistent density and strength. These processes often result in higher material usage and longer cycle times compared to structural foam molding, which uses a foaming agent to create lighter, rigid parts with less material. Understanding these techniques helps you choose the right molding process based on product requirements like weight, strength, and cost efficiency.

Key Differences Between Structural Foam and Conventional Molding

Structural foam molding uses a specialized gas-injection process to create a lightweight, cellular core within the molded part, resulting in reduced material usage and enhanced strength-to-weight ratio compared to conventional solid molding. Conventional molding typically involves injecting molten plastic into a mold cavity without gas, producing fully dense and uniform parts with higher material consumption and longer cycle times. The key differences lie in the core structure, material efficiency, mechanical properties, and manufacturing speed, making structural foam molding ideal for large, complex parts requiring rigidity and reduced weight.

Material Compatibility and Selection

Structural foam molding offers greater versatility in material compatibility, accommodating a wide range of thermoplastics such as polypropylene, polystyrene, and ABS, which provide improved strength-to-weight ratios. Conventional molding typically relies on solid thermoplastics like polyethylene and polystyrene, often limiting material selection based on the required density and finish. Your choice of molding process directly impacts material performance, cost, and product durability, making careful selection essential for optimizing both functionality and manufacturing efficiency.

Process Efficiency and Cycle Times

Structural foam molding offers improved process efficiency through reduced material usage and lower injection pressures compared to conventional molding, resulting in less wear on machinery. Cycle times in structural foam molding are typically shorter due to faster cooling rates and the inherent lower density of the molded parts, enabling quicker ejection and handling. Conventional molding often experiences longer cycle times due to slower cooling and the need for precise cavity filling under higher pressure conditions.

Design Flexibility and Part Complexity

Structural foam molding offers greater design flexibility and allows for more complex part geometries compared to conventional molding, enabling the creation of lightweight components with hollow sections and intricate internal structures. This process reduces material usage while maintaining strength, making it ideal for large, detailed parts that would be difficult or costly to produce with traditional solid molding techniques. Your choice of molding method directly impacts the feasibility of specific design features and overall product performance in applications requiring complex shapes.

Mechanical Properties of Molded Parts

Structural foam molding produces parts with a cellular core that enhances toughness and impact resistance while reducing weight compared to conventionally molded solid parts. Conventional molding typically yields parts with higher density and uniform mechanical properties, offering superior strength and rigidity for load-bearing applications. Your choice depends on whether lightweight durability or maximum strength is the priority in the final product.

Cost Considerations and Economic Impact

Structural foam molding reduces material costs by using less resin due to its cellular core, leading to lighter parts and decreased overall weight. Conventional molding typically incurs higher expenses from longer cycle times and increased material consumption, impacting production efficiency. The economic impact of structural foam molding includes lower tooling costs and reduced energy consumption, contributing to significant cost savings in high-volume manufacturing.

Typical Applications for Each Molding Method

Structural foam molding is ideal for producing large, lightweight components such as automotive parts, appliance housings, and outdoor furniture due to its ability to create thick-walled, durable products with reduced material usage. Conventional molding excels in manufacturing high-precision, thin-walled items like electronic enclosures, medical devices, and consumer goods where detailed surface finishes and dimensional accuracy are crucial. Choosing the right process impacts your product's performance and cost-effectiveness based on the specific application requirements.

Choosing the Right Molding Process for Your Project

Choosing the right molding process depends on factors like part complexity, strength requirements, and production volume. Structural foam molding offers lightweight, high-strength parts with reduced material use and warp resistance, ideal for large, thick components. Conventional molding suits high-precision, thin-walled parts with detailed features, making it optimal for projects demanding tight tolerances and surface finish quality.

Structural Foam Molding vs Conventional Molding Infographic

libmatt.com

libmatt.com