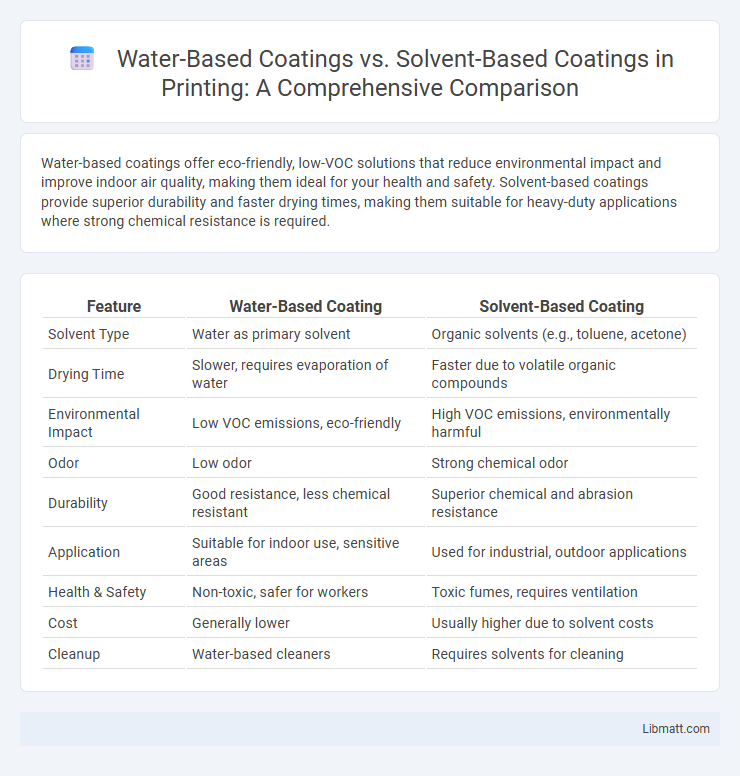

Water-based coatings offer eco-friendly, low-VOC solutions that reduce environmental impact and improve indoor air quality, making them ideal for your health and safety. Solvent-based coatings provide superior durability and faster drying times, making them suitable for heavy-duty applications where strong chemical resistance is required.

Table of Comparison

| Feature | Water-Based Coating | Solvent-Based Coating |

|---|---|---|

| Solvent Type | Water as primary solvent | Organic solvents (e.g., toluene, acetone) |

| Drying Time | Slower, requires evaporation of water | Faster due to volatile organic compounds |

| Environmental Impact | Low VOC emissions, eco-friendly | High VOC emissions, environmentally harmful |

| Odor | Low odor | Strong chemical odor |

| Durability | Good resistance, less chemical resistant | Superior chemical and abrasion resistance |

| Application | Suitable for indoor use, sensitive areas | Used for industrial, outdoor applications |

| Health & Safety | Non-toxic, safer for workers | Toxic fumes, requires ventilation |

| Cost | Generally lower | Usually higher due to solvent costs |

| Cleanup | Water-based cleaners | Requires solvents for cleaning |

Introduction to Coating Technologies

Water-based coatings utilize water as the primary solvent, significantly reducing volatile organic compound (VOC) emissions and offering enhanced environmental safety compared to solvent-based coatings, which rely on organic solvents that contribute to higher VOC levels and potential health risks. Advances in water-based coating technologies have improved their durability, drying time, and adhesion properties, making them competitive alternatives in industries such as automotive, construction, and packaging. Solvent-based coatings remain favored for applications requiring superior chemical resistance and hardness, but regulatory pressures and sustainability goals are accelerating the shift toward water-based formulations.

Defining Water-Based Coatings

Water-based coatings consist primarily of water as the solvent, making them low in volatile organic compounds (VOCs) and environmentally friendly compared to solvent-based coatings. These coatings offer excellent adhesion, quick drying times, and reduced odor, making them ideal for indoor applications and health-conscious users. Your choice of water-based coating supports sustainability while delivering durable, high-quality finishes on a variety of surfaces.

Understanding Solvent-Based Coatings

Solvent-based coatings contain volatile organic compounds (VOCs) that evaporate as the coating dries, providing a durable finish with excellent adhesion and chemical resistance. These coatings are widely used in industrial applications due to their superior hardness and ability to withstand harsh environmental conditions. However, solvent-based coatings pose health and environmental risks, necessitating proper ventilation and safety measures during application.

Key Differences: Water-Based vs. Solvent-Based Coatings

Water-based coatings utilize water as the primary solvent, resulting in lower volatile organic compound (VOC) emissions and reduced environmental impact compared to solvent-based coatings, which rely on organic solvents. Solvent-based coatings typically offer faster drying times and superior durability but pose higher risks due to flammability and toxicity. The key differences also include application methods, with water-based coatings favoring easier cleanup and compatibility with sensitive surfaces, while solvent-based coatings provide enhanced resistance to chemicals and weathering.

Environmental Impact and Sustainability

Water-based coatings significantly reduce volatile organic compound (VOC) emissions compared to solvent-based coatings, making them a more environmentally friendly choice that helps lower air pollution and health risks. They use water as the primary carrier, which minimizes hazardous waste and energy consumption during manufacturing and application, supporting sustainable practices. Choosing your coating with water-based formulations contributes to eco-conscious projects while maintaining durability and performance.

Performance and Durability Comparison

Water-based coatings offer excellent durability with enhanced resistance to cracking, peeling, and fading, making them suitable for long-term applications in both interior and exterior environments. Solvent-based coatings generally provide superior chemical resistance and faster drying times, resulting in a tougher, more resilient surface under harsh conditions. Your choice between these coatings should consider the specific performance needs, environmental impact, and maintenance requirements of the project for optimal results.

Application Methods and Techniques

Water-based coatings typically require spray, roller, or brush application methods that emphasize quick drying and easy cleanup with water, making them suitable for indoor environments and projects demanding low VOC emissions. Solvent-based coatings often need specialized equipment such as high-pressure spray guns or dipping tanks to ensure uniform thickness and adhesion, especially on metal or industrial surfaces, with longer drying times requiring controlled ventilation. Your choice of application technique should consider substrate type, environmental regulations, and desired finish durability to optimize performance and safety.

Health and Safety Considerations

Water-based coatings emit fewer volatile organic compounds (VOCs), significantly reducing indoor air pollution and health hazards such as respiratory issues or headaches. Solvent-based coatings release higher levels of harmful VOCs, posing risks of fire, toxicity, and long-term environmental damage, which require strict safety measures during application. Choosing water-based coatings enhances your work environment safety by minimizing exposure to hazardous fumes and facilitating easier cleanup without harsh chemicals.

Cost Analysis and Economic Factors

Water-based coatings generally offer lower long-term costs due to reduced regulatory fees and lower volatile organic compound (VOC) emissions, minimizing environmental compliance expenses. Solvent-based coatings often have higher initial costs related to health and safety protocols, ventilation requirements, and disposal of hazardous waste. Economic factors also favor water-based coatings in industries prioritizing sustainability and operating in regions with stringent environmental regulations.

Choosing the Right Coating for Your Project

Water-based coatings offer low VOC emissions and quick drying times, making them ideal for indoor applications requiring eco-friendly solutions and minimal odor. Solvent-based coatings provide superior durability and resistance to harsh conditions, suitable for exterior projects exposed to extreme weather or heavy wear. Selecting the right coating depends on project requirements such as environmental impact, surface type, and performance expectations.

Water-based coating vs solvent-based coating Infographic

libmatt.com

libmatt.com