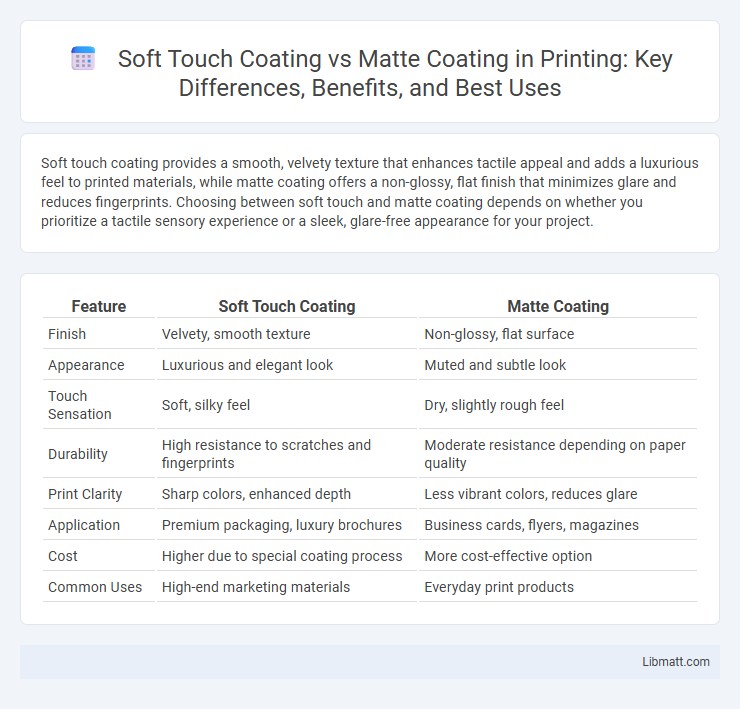

Soft touch coating provides a smooth, velvety texture that enhances tactile appeal and adds a luxurious feel to printed materials, while matte coating offers a non-glossy, flat finish that minimizes glare and reduces fingerprints. Choosing between soft touch and matte coating depends on whether you prioritize a tactile sensory experience or a sleek, glare-free appearance for your project.

Table of Comparison

| Feature | Soft Touch Coating | Matte Coating |

|---|---|---|

| Finish | Velvety, smooth texture | Non-glossy, flat surface |

| Appearance | Luxurious and elegant look | Muted and subtle look |

| Touch Sensation | Soft, silky feel | Dry, slightly rough feel |

| Durability | High resistance to scratches and fingerprints | Moderate resistance depending on paper quality |

| Print Clarity | Sharp colors, enhanced depth | Less vibrant colors, reduces glare |

| Application | Premium packaging, luxury brochures | Business cards, flyers, magazines |

| Cost | Higher due to special coating process | More cost-effective option |

| Common Uses | High-end marketing materials | Everyday print products |

Introduction to Soft Touch and Matte Coatings

Soft touch coating offers a velvety, smooth texture that enhances the tactile experience of printed materials, creating a luxurious and sophisticated feel. Matte coating provides a non-glossy, flat finish that reduces glare and fingerprints, improving readability and giving a subtle, elegant appearance. Both coatings serve distinct aesthetic and functional purposes in packaging, marketing materials, and print media, catering to different design preferences and usability requirements.

Defining Soft Touch Coating

Soft touch coating is a specialized surface finish that imparts a velvety, smooth texture to printed materials, enhancing tactile appeal and perceived quality. Unlike matte coating, which primarily aims to reduce glare and provide a non-reflective surface, soft touch coating emphasizes a luxurious feel with a rubber-like softness. It is commonly used in premium packaging, business cards, and book covers to evoke a sophisticated, high-end experience.

Understanding Matte Coating

Matte coating provides a non-glossy, smooth finish that reduces glare and fingerprints, making it ideal for printed materials requiring a sophisticated, understated look. Unlike soft touch coating, which adds a velvety texture to enhance tactile experience, matte coating emphasizes visual softness and subtlety without altering the surface feel significantly. This coating is commonly used in packaging, business cards, and brochures where readability under various lighting conditions and a professional aesthetic are paramount.

Key Differences Between Soft Touch and Matte

Soft touch coating offers a velvety, tactile finish that enhances grip and provides a luxurious feel, while matte coating delivers a flat, non-reflective surface that reduces glare and fingerprint visibility. Soft touch coatings often incorporate elastomeric or polymer layers for durability and a smooth texture, whereas matte coatings rely on light-diffusing surfaces to achieve their subdued appearance. These coatings differ significantly in sensory experience and functional benefits, with soft touch emphasizing texture and comfort, and matte prioritizing visual subtlety and anti-glare properties.

Appearance and Texture Comparison

Soft touch coating offers a smooth, velvety texture that enhances tactile appeal, creating a premium, luxurious finish. Matte coating provides a non-reflective, flat appearance that reduces glare and offers a subtle, sophisticated look. Both coatings enhance visual aesthetics, but soft touch emphasizes tactile sensation while matte focuses on a muted, elegant surface.

Durability and Resistance Features

Soft touch coating offers superior durability with enhanced resistance to scratches, fingerprints, and abrasions, making it ideal for high-contact surfaces. Matte coating provides moderate resistance to glare and fingerprints but is generally less durable against physical wear compared to soft touch finishes. Both coatings improve product longevity, but soft touch coatings excel in maintaining appearance under frequent handling and rough conditions.

Applications in Packaging and Printing

Soft touch coating offers a velvety texture that enhances tactile appeal, making it ideal for high-end packaging such as luxury cosmetics and premium electronics boxes. Matte coating provides a non-reflective, smooth finish that reduces glare and improves readability, frequently used in food packaging, book covers, and brochures. Both coatings protect printed materials but cater to different sensory experiences and visual effects in packaging applications.

Cost Considerations

Soft touch coating typically incurs higher costs due to specialized materials and application processes, making it a premium choice for enhancing tactile experience and perceived quality. Matte coating, while still providing a smooth, non-glossy finish, is generally more affordable and suitable for budget-conscious projects seeking a sophisticated look. When deciding, your budget allocation should weigh the added expense of soft touch coating against the desired visual and tactile impact.

Environmental Impact and Sustainability

Soft touch coating typically uses solvent-based materials that can emit volatile organic compounds (VOCs), contributing to environmental pollution, whereas matte coating often utilizes water-based or UV coatings that are more eco-friendly. Matte coatings generally require less energy for curing and have a lower carbon footprint compared to soft touch coatings. Sustainable practices favor matte coatings due to their recyclability and reduced environmental impact throughout the production cycle.

Choosing the Right Coating for Your Project

Soft touch coating offers a velvety, tactile finish that enhances the sensory experience and adds a premium feel to packaging or printed materials. Matte coating provides a non-reflective, smooth surface that reduces glare and improves readability, making it ideal for text-heavy designs. Selecting the right coating depends on the desired aesthetic, tactile sensation, and the specific needs of your project such as durability and visual impact.

Soft touch coating vs matte coating Infographic

libmatt.com

libmatt.com