Polycarbonate shields offer superior impact resistance and durability compared to acrylic shields, making them ideal for high-impact protection and long-term use. Your choice depends on the balance between clarity and toughness, as acrylic provides better optical clarity while polycarbonate excels in strength.

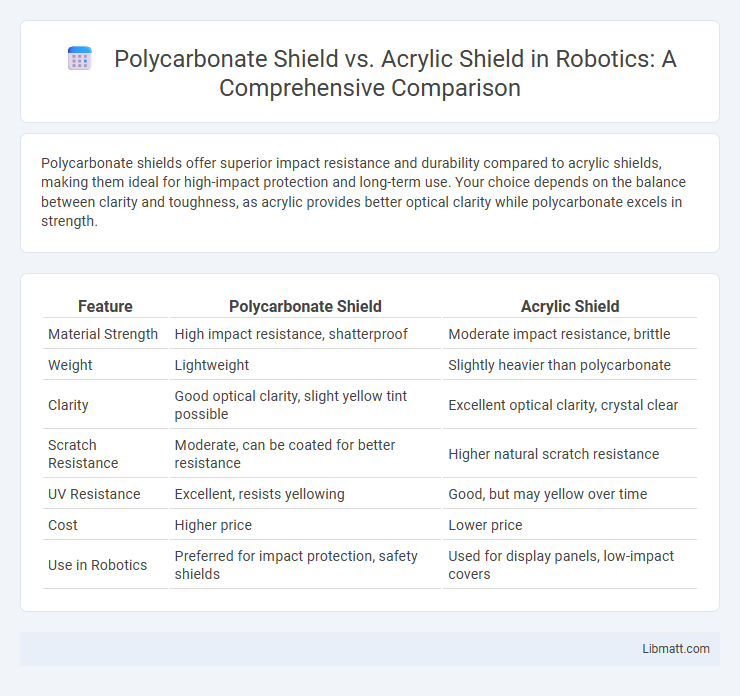

Table of Comparison

| Feature | Polycarbonate Shield | Acrylic Shield |

|---|---|---|

| Material Strength | High impact resistance, shatterproof | Moderate impact resistance, brittle |

| Weight | Lightweight | Slightly heavier than polycarbonate |

| Clarity | Good optical clarity, slight yellow tint possible | Excellent optical clarity, crystal clear |

| Scratch Resistance | Moderate, can be coated for better resistance | Higher natural scratch resistance |

| UV Resistance | Excellent, resists yellowing | Good, but may yellow over time |

| Cost | Higher price | Lower price |

| Use in Robotics | Preferred for impact protection, safety shields | Used for display panels, low-impact covers |

Introduction to Polycarbonate and Acrylic Shields

Polycarbonate shields are renowned for their impact resistance and high durability, making them ideal for safety applications and protective barriers. Acrylic shields offer exceptional optical clarity and weather resistance, favored in display cases and decorative panels. Both materials provide lightweight protection but differ significantly in strength, flexibility, and cost efficiency.

Material Composition and Properties

Polycarbonate shields are composed of thermoplastic polymer known for high impact resistance, clarity, and thermal stability, making them durable and virtually unbreakable under stress. Acrylic shields consist of polymethyl methacrylate (PMMA), offering excellent optical clarity and UV resistance but with lower impact strength and higher brittleness compared to polycarbonate. These material properties influence their respective applications, with polycarbonate preferred for environments requiring high impact durability and acrylic favored where superior transparency and scratch resistance are critical.

Impact Resistance: Polycarbonate vs Acrylic

Polycarbonate shields offer superior impact resistance, able to withstand high-velocity impacts without cracking or shattering, making them ideal for protective applications in security and industrial environments. Acrylic shields, while offering decent clarity and scratch resistance, are more prone to cracking or breaking under strong impact forces, limiting their use in high-risk settings. The inherent toughness of polycarbonate materials provides enhanced durability and safety compared to the more brittle nature of acrylic shields.

Optical Clarity and Light Transmission

Polycarbonate shields offer excellent impact resistance but typically have slightly lower optical clarity and light transmission compared to acrylic shields, which are known for their superior transparency and clarity. Acrylic provides up to 92% light transmission, making it ideal for applications requiring bright, clear visibility, while polycarbonate usually transmits around 88%. Your choice depends on whether you prioritize durability or the highest optical clarity and light transmission for clear viewing experiences.

Weight and Ease of Handling

Polycarbonate shield is significantly lighter than acrylic shield, making it easier for you to handle and install without strain. Its superior impact resistance combined with lightweight properties ensures better maneuverability in various applications. Acrylic shields, while more rigid, tend to be heavier and more prone to cracking under stress, reducing ease of handling.

Durability and Longevity

Polycarbonate shields exhibit superior durability compared to acrylic shields, with impact resistance up to 250 times greater, making them ideal for high-stress environments. Acrylic shields, while less durable, offer good clarity and resistance to UV light but are more prone to cracking and scratching over time. The longevity of polycarbonate shields outperforms acrylic, maintaining structural integrity and transparency even under harsh conditions, which reduces the need for frequent replacements.

Scratch Resistance and Maintenance

Polycarbonate shields offer superior scratch resistance compared to acrylic shields due to their tougher molecular structure, making them more durable in high-impact environments. Maintenance of polycarbonate shields is simpler as they are less prone to surface damage and require gentle cleaning agents to preserve clarity. Acrylic shields, while more affordable, scratch easily and often need frequent polishing or replacement to maintain optimal transparency.

Cost Comparison: Polycarbonate vs Acrylic

Polycarbonate shields generally cost more upfront than acrylic shields due to their superior impact resistance and durability. Acrylic shields offer a budget-friendly option with lower initial costs but may require more frequent replacement over time, impacting long-term expenses. Choosing polycarbonate can save your money over time by reducing maintenance and replacement needs despite the higher initial investment.

Typical Applications and Uses

Polycarbonate shields are widely used in safety equipment such as riot gear, face shields, and machine guards due to their high impact resistance and durability. Acrylic shields find common applications in display cases, protective barriers, and signage where optical clarity and scratch resistance are prioritized over impact strength. Both materials serve in protective barriers and enclosures but are selected based on the specific requirements of strength, weight, and transparency.

Choosing the Right Shield: Key Considerations

When selecting between polycarbonate and acrylic shields, consider impact resistance, as polycarbonate offers superior durability and shatter resistance ideal for high-risk environments. Acrylic shields provide clearer optical clarity and greater scratch resistance but are less impact-resistant, making them suitable for low-risk applications. Weight and cost also influence choice; polycarbonate is typically heavier and more expensive, while acrylic is lighter and more budget-friendly.

Polycarbonate Shield vs Acrylic Shield Infographic

libmatt.com

libmatt.com