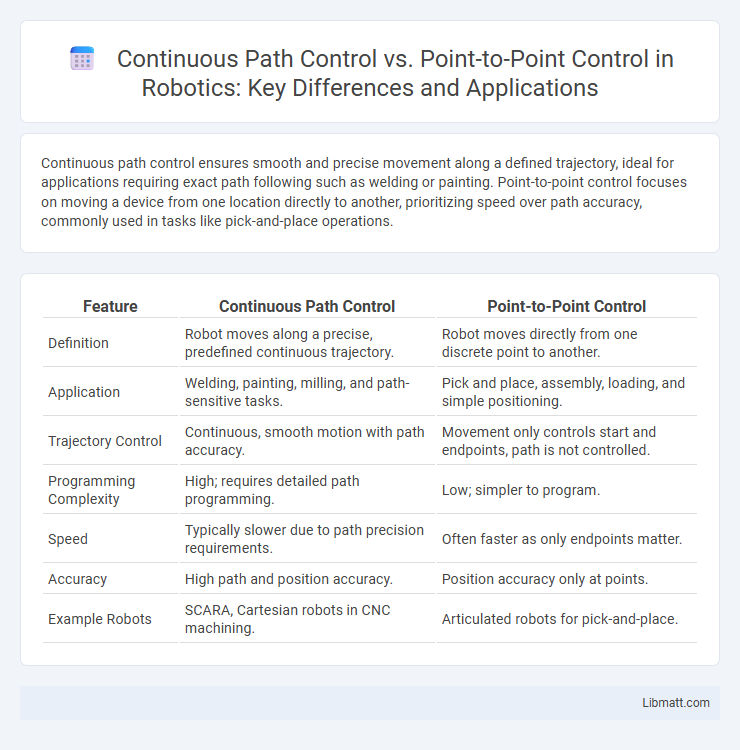

Continuous path control ensures smooth and precise movement along a defined trajectory, ideal for applications requiring exact path following such as welding or painting. Point-to-point control focuses on moving a device from one location directly to another, prioritizing speed over path accuracy, commonly used in tasks like pick-and-place operations.

Table of Comparison

| Feature | Continuous Path Control | Point-to-Point Control |

|---|---|---|

| Definition | Robot moves along a precise, predefined continuous trajectory. | Robot moves directly from one discrete point to another. |

| Application | Welding, painting, milling, and path-sensitive tasks. | Pick and place, assembly, loading, and simple positioning. |

| Trajectory Control | Continuous, smooth motion with path accuracy. | Movement only controls start and endpoints, path is not controlled. |

| Programming Complexity | High; requires detailed path programming. | Low; simpler to program. |

| Speed | Typically slower due to path precision requirements. | Often faster as only endpoints matter. |

| Accuracy | High path and position accuracy. | Position accuracy only at points. |

| Example Robots | SCARA, Cartesian robots in CNC machining. | Articulated robots for pick-and-place. |

Introduction to Motion Control Systems

Motion control systems are essential in automation, enabling precise manipulation of mechanical components through two primary methods: continuous path control and point-to-point control. Continuous path control ensures smooth, coordinated movement along a predefined trajectory, crucial for CNC machining and robotic welding. In contrast, point-to-point control directs motion from one specific position to another without regard for the path taken, ideal for pick-and-place operations and assembly tasks.

Defining Continuous Path Control

Continuous path control is a method in CNC machining and robotics where the tool or end effector follows a pre-defined trajectory smoothly and continuously without interruption, enabling precise shaping of complex surfaces. This control type is essential in applications requiring coordinated multi-axis movements, such as milling, welding, and painting, where maintaining the tool path integrity affects the final product quality. Unlike point-to-point control, which moves between discrete positions without focus on the intermediate path, continuous path control ensures constant motion, enhancing accuracy and surface finish.

Understanding Point-to-Point Control

Point-to-point control directs a machine to move precisely between specific coordinates without controlling the path taken, making it ideal for tasks like pick-and-place or drilling. This control method prioritizes end positions rather than continuous motion, resulting in faster yet less smooth operations compared to continuous path control. Understanding how point-to-point control functions is essential for optimizing Your automation processes where exact positioning at discrete points is required.

Key Differences Between Continuous Path and Point-to-Point Control

Continuous path control guides a machine along a precise, uninterrupted trajectory, ideal for applications requiring smooth and exact motion such as welding or cutting. Point-to-point control moves a machine from one discrete position to another without controlling the path in between, making it suitable for operations like pick-and-place or assembly tasks. Your choice depends on whether the process demands accurate path following or simply reaching specific coordinates.

Applications of Continuous Path Control

Continuous path control is essential in applications requiring smooth and precise tool movement along complex trajectories, such as CNC machining, robotic welding, and 3D printing. It enables high-quality finishes and intricate shapes by continuously adjusting the tool path in real time. Industries like aerospace, automotive, and electronics heavily rely on continuous path control to ensure accuracy and efficiency in manufacturing processes.

Use Cases for Point-to-Point Control

Point-to-point control is ideal for applications requiring precise positioning at specific locations, such as robotic pick-and-place operations, assembly line tasks, and CNC machining where movement between discrete points is essential. Your systems benefit from this control mode when accuracy and repeatability at defined coordinates are critical, without the need for continuous motion. It is commonly employed in automated manufacturing processes where speed and exact placement optimize efficiency and reduce errors.

Advantages of Continuous Path Control

Continuous path control offers precise regulation of tool or machine movement along complex trajectories, ideal for tasks requiring smooth curves and intricate shapes such as CNC machining and robotic welding. It enhances surface finish quality and reduces cycle time by maintaining constant velocity and acceleration, minimizing abrupt stops and starts. Your manufacturing process benefits from improved accuracy and flexibility in producing complex geometries compared to point-to-point control, which only targets discrete positions.

Benefits and Limitations of Point-to-Point Control

Point-to-point control offers precise and efficient movement between specific positions, making it ideal for tasks such as pick-and-place operations or simple assembly processes. This method benefits from simpler programming and reduced system complexity, which lowers cost and maintenance requirements. However, point-to-point control is limited by its inability to manage continuous motion smoothly, resulting in less optimal performance for applications needing fluid, uninterrupted paths.

Selecting the Right Control Method for Your Application

Choosing between continuous path control and point-to-point control depends on your application's precision and motion requirements. Continuous path control is ideal for tasks demanding smooth, coordinated movements with exact trajectory adherence, such as welding or painting robots. Point-to-point control suits applications focused on reaching specific positions quickly, like pick-and-place operations or basic assembly tasks.

Future Trends in Motion Control Technologies

Continuous path control enhances manufacturing precision by enabling fluid, uninterrupted tool motion, essential for applications like robotics and CNC machining. Future trends emphasize integrating AI and machine learning to optimize motion trajectories, reducing energy consumption and increasing speed without compromising accuracy. Your operations can benefit from adaptive control systems that combine continuous path and point-to-point control to deliver unprecedented flexibility and efficiency in dynamic environments.

Continuous path control vs Point-to-point control Infographic

libmatt.com

libmatt.com