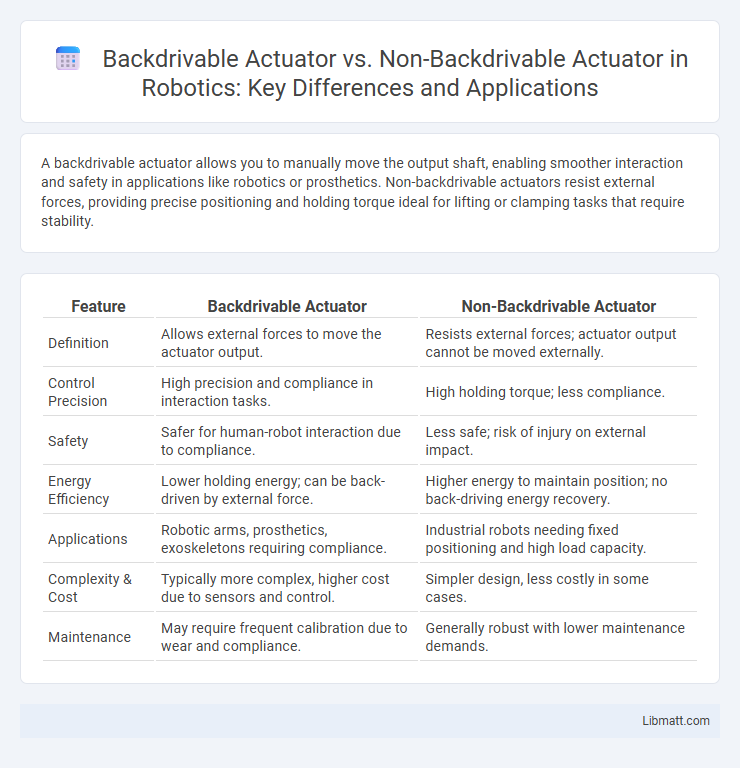

A backdrivable actuator allows you to manually move the output shaft, enabling smoother interaction and safety in applications like robotics or prosthetics. Non-backdrivable actuators resist external forces, providing precise positioning and holding torque ideal for lifting or clamping tasks that require stability.

Table of Comparison

| Feature | Backdrivable Actuator | Non-Backdrivable Actuator |

|---|---|---|

| Definition | Allows external forces to move the actuator output. | Resists external forces; actuator output cannot be moved externally. |

| Control Precision | High precision and compliance in interaction tasks. | High holding torque; less compliance. |

| Safety | Safer for human-robot interaction due to compliance. | Less safe; risk of injury on external impact. |

| Energy Efficiency | Lower holding energy; can be back-driven by external force. | Higher energy to maintain position; no back-driving energy recovery. |

| Applications | Robotic arms, prosthetics, exoskeletons requiring compliance. | Industrial robots needing fixed positioning and high load capacity. |

| Complexity & Cost | Typically more complex, higher cost due to sensors and control. | Simpler design, less costly in some cases. |

| Maintenance | May require frequent calibration due to wear and compliance. | Generally robust with lower maintenance demands. |

Introduction to Backdrivable and Non-Backdrivable Actuators

Backdrivable actuators allow external forces to move the actuator output without motor input, enabling safe and intuitive human-machine interaction commonly used in robotics and prosthetics. Non-backdrivable actuators resist external forces to maintain position without motor power, providing higher load-holding capability ideal for applications like valves and heavy machinery. Understanding these fundamental differences helps in selecting the appropriate actuator type based on load control, energy efficiency, and safety requirements.

Fundamental Principles of Backdrivability

Backdrivable actuators enable motion transfer in both driving and reverse directions due to low mechanical impedance and minimal friction, allowing external forces to move the actuator shaft freely. In contrast, non-backdrivable actuators incorporate high gear ratios or mechanical locks that prevent motion reversal and resist external loads, ensuring positional stability under external forces. Fundamental principles of backdrivability involve designing gear mechanisms and frictional elements to balance torque transmission efficiency with the ability to respond to external forces without damage or loss of control.

Key Features of Backdrivable Actuators

Backdrivable actuators feature high torque sensitivity and low friction, enabling users to manually move the actuator's output shaft without power, which enhances safety and ease of maintenance. These actuators typically incorporate low gear ratios or direct drive mechanisms to allow smooth, responsive motion and precise control. Their ability to resist cause minimal mechanical stress and energy loss makes them ideal for applications requiring human-machine interaction or compliance.

Defining Non-Backdrivable Actuators

Non-backdrivable actuators are mechanical devices designed to resist motion when external forces attempt to move their output shaft, providing inherent stability and positioning without continuous power input. These actuators typically incorporate gear mechanisms such as worm gears or multi-stage planetary gears, which create a high gear ratio that prevents the load from driving the actuator backward. Non-backdrivability is essential in applications requiring load holding under gravity or safety-critical conditions, minimizing the need for additional braking systems.

Advantages of Backdrivable Actuators

Backdrivable actuators offer enhanced safety and improved human-machine interaction due to their ability to be moved manually when powered off, allowing for easier manual adjustments and force feedback. These actuators provide energy efficiency by enabling energy recovery during backdriving, which is essential in robotics and assistive devices. Their flexibility in dynamic environments makes them ideal for applications requiring precise control and responsiveness, such as prosthetics and collaborative robots.

Benefits of Non-Backdrivable Actuators

Non-backdrivable actuators provide enhanced safety and reliability by preventing unintended motion under load, making them ideal for applications requiring holding positions securely without continuous power. Their inherent mechanical locking capability reduces energy consumption and wear, leading to increased system efficiency and longevity. These actuators are commonly used in robotics, automotive systems, and industrial machinery where precision and stability are critical.

Common Applications and Use Cases

Backdrivable actuators are commonly used in robotic arms, prosthetics, and haptic devices where precise human interaction and force feedback are critical for safe and responsive control. Non-backdrivable actuators find frequent application in lifting equipment, locking mechanisms, and automation systems requiring secure hold under load without manual override. Understanding these distinctions helps you select the appropriate actuator type to enhance performance and safety in your mechanical design.

Performance Comparison: Efficiency and Control

Backdrivable actuators offer superior efficiency by allowing energy to flow bidirectionally, enabling smoother motion control and enhanced responsiveness in dynamic applications. Non-backdrivable actuators provide higher load-holding capability and position stability but can suffer from reduced energy efficiency due to unidirectional force transmission. Selecting the appropriate actuator affects Your system's overall performance, balancing energy consumption and precise control based on the application's specific demands.

Safety Considerations in Actuator Selection

Backdrivable actuators enhance safety by allowing manual override during power loss or emergency, preventing potential damage or injury. Non-backdrivable actuators resist external forces, providing stable positioning but may pose risks if obstruction occurs without fail-safe mechanisms. Your actuator choice should weigh the importance of manual control against load holding requirements to ensure optimal safety in application.

Choosing the Right Actuator for Your Application

Backdrivable actuators allow manual or external force to move the actuator shaft, offering safer operation and easier manual override in robotic and automation applications. Non-backdrivable actuators provide higher torque hold without power, ideal for lifting or holding loads securely in place when power is off. Your choice depends on whether you need manual intervention flexibility or high load-holding capacity for your specific application.

Backdrivable actuator vs Non-backdrivable actuator Infographic

libmatt.com

libmatt.com