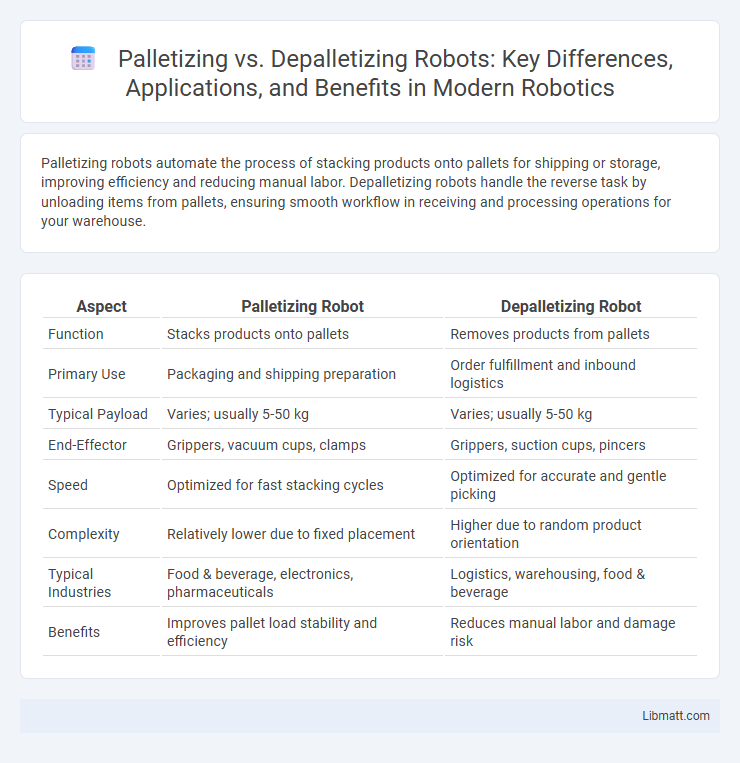

Palletizing robots automate the process of stacking products onto pallets for shipping or storage, improving efficiency and reducing manual labor. Depalletizing robots handle the reverse task by unloading items from pallets, ensuring smooth workflow in receiving and processing operations for your warehouse.

Table of Comparison

| Aspect | Palletizing Robot | Depalletizing Robot |

|---|---|---|

| Function | Stacks products onto pallets | Removes products from pallets |

| Primary Use | Packaging and shipping preparation | Order fulfillment and inbound logistics |

| Typical Payload | Varies; usually 5-50 kg | Varies; usually 5-50 kg |

| End-Effector | Grippers, vacuum cups, clamps | Grippers, suction cups, pincers |

| Speed | Optimized for fast stacking cycles | Optimized for accurate and gentle picking |

| Complexity | Relatively lower due to fixed placement | Higher due to random product orientation |

| Typical Industries | Food & beverage, electronics, pharmaceuticals | Logistics, warehousing, food & beverage |

| Benefits | Improves pallet load stability and efficiency | Reduces manual labor and damage risk |

Introduction to Palletizing and Depalletizing Robots

Palletizing and depalletizing robots are essential automation solutions designed to handle the stacking and unstacking of products on pallets efficiently. Palletizing robots arrange items into organized layers on pallets, enhancing packaging speed and accuracy, while depalletizing robots dismantle pallet loads for sorting and processing. You can optimize warehouse operations and reduce labor costs by integrating these robots into your supply chain management.

Key Differences Between Palletizing and Depalletizing Robots

Palletizing robots are designed to automate the stacking of products onto pallets for storage or shipment, optimizing load patterns and ensuring stability. Depalletizing robots specialize in unloading items from pallets, sorting, and preparing them for further processing or distribution. The key differences lie in their operational focus: palletizing robots emphasize precision stacking and load configuration, while depalletizing robots focus on efficient deconstruction and handling varied load orientations.

How Palletizing Robots Work

Palletizing robots work by using advanced sensors and vision systems to accurately pick and place products onto pallets in predefined patterns, optimizing space and stability. Equipped with multi-axis robotic arms and end-effectors, these robots handle varying product sizes and weights with precision and speed, ensuring efficient stacking processes. Integration with warehouse management systems enhances real-time coordination and inventory control during pallet loading.

How Depalletizing Robots Work

Depalletizing robots operate by using advanced vision systems and sensors to identify and locate products on pallets, enabling precise handling and unloading. Equipped with articulated arms and specialized grippers, these robots efficiently remove items layer by layer, minimizing damage and maximizing speed. Integration with automation software ensures seamless coordination with warehouse operations for real-time inventory management.

Benefits of Robotic Palletizing Systems

Robotic palletizing systems significantly enhance operational efficiency by automating the stacking of products, reducing labor costs and minimizing workplace injuries associated with manual handling. These systems offer high precision and consistency, ensuring optimal load stability and maximizing storage space, which improves overall supply chain management. Investing in robotic palletizers allows your facility to achieve faster cycle times and scalable solutions tailored to fluctuating production demands.

Advantages of Robotic Depalletizing Solutions

Robotic depalletizing solutions offer significant advantages such as increased efficiency and precision in unloading products from pallets, reducing manual labor and minimizing damage to goods. These systems can handle various product types and pallet configurations, enhancing flexibility in your supply chain operations. By automating depalletizing tasks, you improve workplace safety and throughput, leading to lower operational costs and faster order fulfillment.

Application Areas: Palletizing vs Depalletizing Robots

Palletizing robots are primarily utilized in manufacturing, warehousing, and distribution centers to automate the stacking of products onto pallets, enhancing efficiency in packaging and shipping processes. Depalletizing robots are commonly employed in food and beverage, pharmaceuticals, and logistics industries to unload products from pallets for inspection, sorting, or further processing. Both robot types optimize material handling workflows but target distinct stages of supply chain operations--palletizing focuses on product consolidation, while depalletizing emphasizes product separation and preparation.

Choosing the Right Robot: Factors to Consider

Choosing the right robot for palletizing versus depalletizing depends on factors such as load capacity, speed requirements, and workspace layout. Palletizing robots typically require precision for stacking items uniformly, while depalletizing robots need versatile gripping mechanisms to handle varied product shapes and weights. Assessing your production volume and flexibility needs ensures optimal robot selection for efficiency and reliability.

Latest Innovations in Palletizing and Depalletizing Automation

Latest innovations in palletizing and depalletizing robots include advanced AI-driven vision systems that enhance precision and speed during load handling. Collaborative robots (cobots) equipped with real-time adaptive sensing optimize your automation workflow by reducing downtime and accommodating varying package sizes. Enhanced end-of-arm tooling and energy-efficient servo motors significantly improve payload capacity and operational efficiency in modern palletizing and depalletizing systems.

Future Trends in Robotic Material Handling

Future trends in robotic material handling include the development of intelligent palletizing and depalletizing robots equipped with advanced AI and machine learning capabilities for enhanced precision and adaptability. Collaborative robots (cobots) are becoming essential, integrating seamlessly with human operators to optimize workflow efficiency in warehouses and manufacturing plants. Your operations can benefit from these innovations through increased automation flexibility, reduced labor costs, and improved safety standards.

Palletizing vs Depalletizing Robot Infographic

libmatt.com

libmatt.com