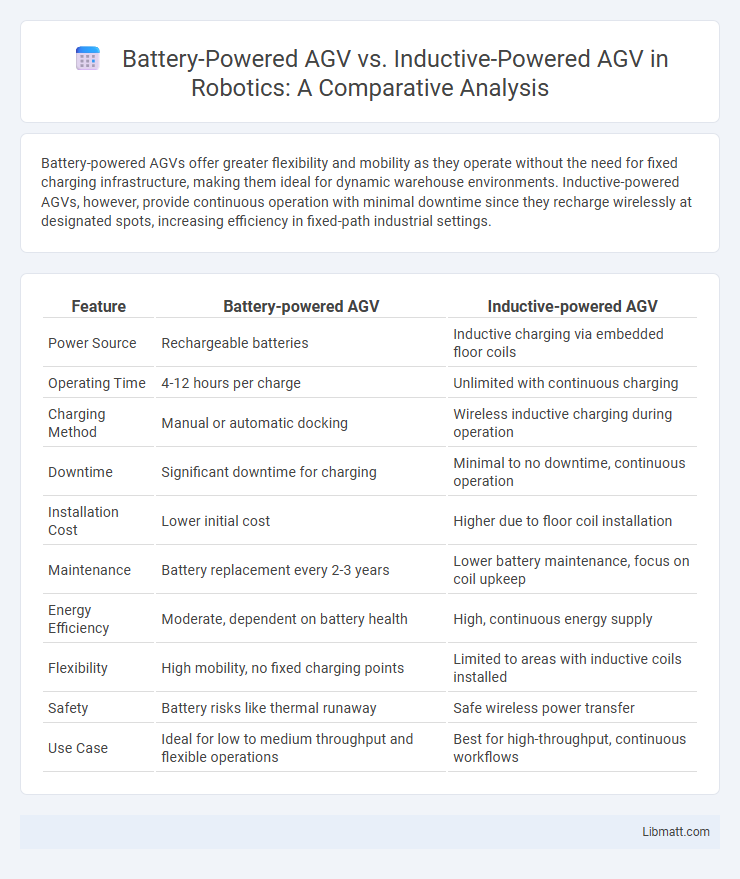

Battery-powered AGVs offer greater flexibility and mobility as they operate without the need for fixed charging infrastructure, making them ideal for dynamic warehouse environments. Inductive-powered AGVs, however, provide continuous operation with minimal downtime since they recharge wirelessly at designated spots, increasing efficiency in fixed-path industrial settings.

Table of Comparison

| Feature | Battery-powered AGV | Inductive-powered AGV |

|---|---|---|

| Power Source | Rechargeable batteries | Inductive charging via embedded floor coils |

| Operating Time | 4-12 hours per charge | Unlimited with continuous charging |

| Charging Method | Manual or automatic docking | Wireless inductive charging during operation |

| Downtime | Significant downtime for charging | Minimal to no downtime, continuous operation |

| Installation Cost | Lower initial cost | Higher due to floor coil installation |

| Maintenance | Battery replacement every 2-3 years | Lower battery maintenance, focus on coil upkeep |

| Energy Efficiency | Moderate, dependent on battery health | High, continuous energy supply |

| Flexibility | High mobility, no fixed charging points | Limited to areas with inductive coils installed |

| Safety | Battery risks like thermal runaway | Safe wireless power transfer |

| Use Case | Ideal for low to medium throughput and flexible operations | Best for high-throughput, continuous workflows |

Introduction to AGV Power Systems

Battery-powered AGVs utilize rechargeable lithium-ion or lead-acid batteries, providing flexibility and longer operational range without the need for continuous power infrastructure. Inductive-powered AGVs rely on electromagnetic fields generated by floor-embedded coils to supply power wirelessly, enabling continuous operation with minimal downtime. Both systems present unique advantages in energy efficiency, installation complexity, and maintenance requirements, influencing their suitability for different industrial environments.

Overview of Battery-powered AGVs

Battery-powered Automated Guided Vehicles (AGVs) utilize rechargeable lithium-ion or lead-acid batteries, providing high mobility and operational flexibility across various industrial environments. These AGVs offer extended runtime and easy recharging capabilities, making them ideal for dynamic material handling in warehouses, manufacturing plants, and distribution centers. Battery-powered AGVs reduce infrastructure costs by eliminating the need for embedded guide paths or induction loops, enhancing scalability and deployment speed.

Overview of Inductive-powered AGVs

Inductive-powered AGVs utilize wireless charging systems embedded in the floor, enabling continuous operation without manual battery swaps or downtime. These systems rely on electromagnetic fields to transfer energy efficiently to the vehicle's onboard battery while it navigates predefined routes. This technology enhances operational uptime and reduces maintenance costs compared to conventional battery-powered AGVs that require scheduled recharging sessions.

Energy Efficiency Comparison

Battery-powered AGVs typically offer higher energy efficiency due to their ability to store and use energy more flexibly, reducing waste during idle times. Inductive-powered AGVs rely on continuous energy transfer through electromagnetic fields, which can result in energy loss and lower overall efficiency. Your choice of AGV should consider the specific application's energy demands and operational cycles to maximize efficiency and cost savings.

Maintenance and Operational Costs

Battery-powered AGVs require regular battery replacements and charging, leading to higher maintenance costs and downtime, while inductive-powered AGVs benefit from continuous wireless charging, reducing battery wear and extending operational hours. Operational expenses for battery-powered AGVs include energy consumption during charging cycles and potential battery disposal fees, whereas inductive systems have higher initial installation costs but lower ongoing energy and maintenance expenses. Your choice impacts long-term cost-efficiency, with inductive-powered AGVs offering more consistent performance and reduced maintenance demands.

Infrastructure and Installation Requirements

Battery-powered AGVs require minimal infrastructure modifications, relying on onboard rechargeable batteries and simple charging stations, making installation faster and more flexible. Inductive-powered AGVs demand embedded inductive charging loops or pads within floors, necessitating significant upfront infrastructure changes and precise placement for effective energy transfer. Your choice impacts installation complexity, with battery-powered systems offering easier setup while inductive systems provide continuous charging capabilities without manual intervention.

Flexibility and Scalability

Battery-powered AGVs offer greater flexibility as they can operate freely without the constraints of embedded guide paths, allowing for easy reprogramming and route adjustments to suit dynamic environments. Inductive-powered AGVs rely on fixed inductive wires installed in the floor, limiting scalability and flexibility to predefined routes and making them less adaptable to changes in layout or increased operational demand. Your choice between the two should consider the need for adaptable navigation versus consistent, defined pathways to optimize productivity in varying facility designs.

Safety and Reliability Considerations

Battery-powered AGVs offer flexibility and mobility, but require careful monitoring of battery health to prevent unexpected downtimes and safety hazards like overheating or electrical faults. Inductive-powered AGVs provide continuous power through embedded floor coils, enhancing reliability and reducing the risk of power-related interruptions, but the system's safety depends on proper installation and electromagnetic field control to avoid interference. For your facility, choosing between these options hinges on balancing the safety protocols for battery management against the consistent, maintenance-light operation ensured by inductive power systems.

Environmental Impact Analysis

Battery-powered AGVs generate environmental concerns primarily due to battery production, disposal, and energy consumption, while offering flexibility and zero emissions during operation. Inductive-powered AGVs reduce battery waste and can continuously operate with lower emissions if connected to a green energy source, yet their infrastructure installation and energy losses may increase environmental footprint. Your choice should consider lifecycle emissions, grid energy sources, and maintenance to optimize sustainability in automated material handling solutions.

Choosing the Right AGV Power Solution

When choosing the right AGV power solution, battery-powered AGVs offer flexibility and longer operational range without dependence on embedded infrastructure, making them ideal for dynamic environments. Inductive-powered AGVs provide continuous power through wireless charging, minimizing downtime and eliminating battery maintenance but require precise path guidance and installation of charging pads. Your decision should weigh factors like facility layout, operational uptime needs, and maintenance capabilities to optimize efficiency.

Battery-powered AGV vs Inductive-powered AGV Infographic

libmatt.com

libmatt.com