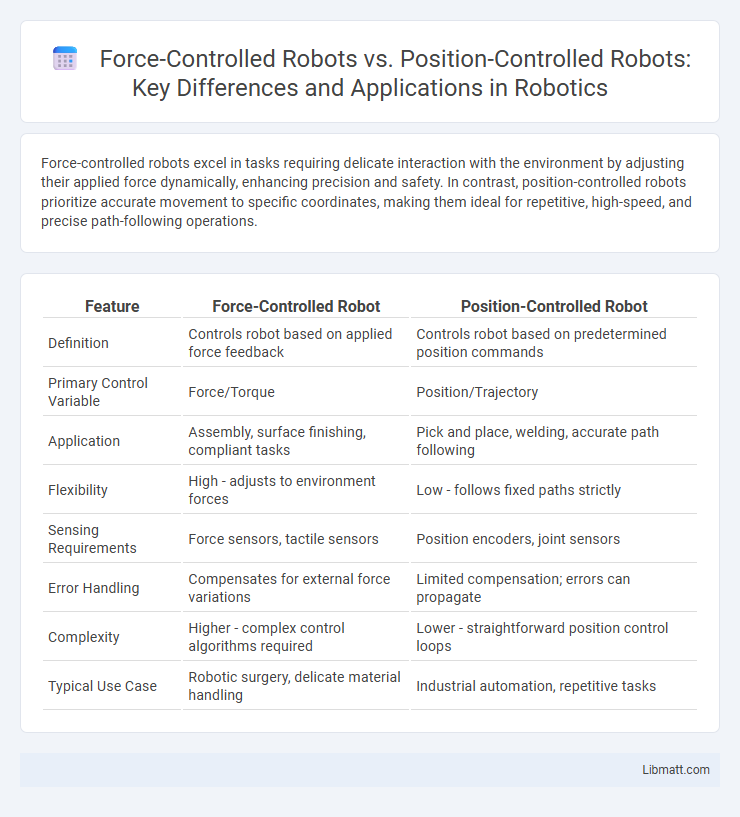

Force-controlled robots excel in tasks requiring delicate interaction with the environment by adjusting their applied force dynamically, enhancing precision and safety. In contrast, position-controlled robots prioritize accurate movement to specific coordinates, making them ideal for repetitive, high-speed, and precise path-following operations.

Table of Comparison

| Feature | Force-Controlled Robot | Position-Controlled Robot |

|---|---|---|

| Definition | Controls robot based on applied force feedback | Controls robot based on predetermined position commands |

| Primary Control Variable | Force/Torque | Position/Trajectory |

| Application | Assembly, surface finishing, compliant tasks | Pick and place, welding, accurate path following |

| Flexibility | High - adjusts to environment forces | Low - follows fixed paths strictly |

| Sensing Requirements | Force sensors, tactile sensors | Position encoders, joint sensors |

| Error Handling | Compensates for external force variations | Limited compensation; errors can propagate |

| Complexity | Higher - complex control algorithms required | Lower - straightforward position control loops |

| Typical Use Case | Robotic surgery, delicate material handling | Industrial automation, repetitive tasks |

Introduction to Robot Control Systems

Force-controlled robots regulate interaction forces with their environment, enhancing precision in tasks requiring delicate touch or variable force application. Position-controlled robots prioritize accurate spatial positioning, ideal for repetitive, pre-defined motion paths without force feedback. Your choice depends on whether adaptive force management or precise spatial accuracy is critical for your robotic application.

What is Force-Controlled Robotics?

Force-controlled robotics refers to a method where robots regulate the force applied during interaction with objects or environments, enhancing precision in tasks like assembly, machining, or delicate manipulation. Unlike position-controlled robots that strictly follow predefined trajectories regardless of contact forces, force-controlled robots use sensors and feedback loops to adjust their movements based on real-time force measurements. This approach improves safety, adaptability, and effectiveness in dynamic or uncertain conditions by maintaining consistent force application and preventing damage to objects or the robot itself.

What is Position-Controlled Robotics?

Position-controlled robotics refers to robotic systems designed to move to and hold specific positions or trajectories with high accuracy using feedback from sensors like encoders or potentiometers. These robots prioritize precise spatial positioning over interaction forces, making them ideal for tasks such as pick-and-place operations, assembly, and machining where exact location control is critical. Unlike force-controlled robots, position-controlled robots do not actively adjust their movements based on force feedback, which limits their adaptability in variable-contact environments.

Key Differences Between Force and Position Control

Force-controlled robots regulate the amount of force exerted during tasks, enabling precise interaction with varying environments and delicate objects. Position-controlled robots focus on following exact trajectories or setpoints, prioritizing spatial accuracy over adaptive force management. Your choice depends on application needs: force control excels in tasks requiring compliant motion, while position control suits precise path execution.

Advantages of Force-Controlled Robots

Force-controlled robots offer superior adaptability in dynamic and unstructured environments by precisely regulating applied forces, enhancing safety and product quality during delicate tasks like assembly and polishing. Their ability to respond to external force variations enables improved interaction with humans and objects, reducing the risk of damage in collaborative robotic applications. This control method also allows for fine tactile feedback, optimizing performance in complex operations such as machining and medical procedures.

Benefits of Position-Controlled Robots

Position-controlled robots offer precise trajectory tracking and accurate path execution, making them ideal for applications requiring high repeatability and consistent positioning. These robots excel in structured environments such as assembly lines and CNC machining, where exact spatial control is critical for quality output. Their straightforward control algorithms result in easier programming and faster response times compared to force-controlled counterparts.

Applications Suited for Force-Controlled Robots

Force-controlled robots excel in applications requiring delicate interaction with environments, such as assembly tasks in electronics manufacturing and surgical robotics, where precise force feedback prevents damage. They are ideal for handling flexible materials, performing surface finishing, and tasks involving variable contact forces, enhancing safety and adaptability. Your processes benefit from reduced errors and improved quality when using force-controlled systems in environments with unpredictable or complex mechanical interactions.

Common Uses for Position-Controlled Robots

Position-controlled robots are commonly used in applications requiring high precision and repeatability, such as assembly lines, pick-and-place tasks, and CNC machining. Their ability to accurately control trajectory and speed makes them suitable for operations like welding, painting, and packaging. These robots excel in environments where predefined paths are essential and external force feedback is less critical.

Challenges and Limitations of Each Control Method

Force-controlled robots struggle with precise positioning due to sensor noise and delays, making tasks that require exact movement challenging. Position-controlled robots face limitations in adapting to dynamic environments, as rigid control can cause damage or failure when unexpected forces occur. Your choice between these methods depends on the specific application's need for accuracy versus adaptability to external forces.

Future Trends in Robotic Control Technologies

Future trends in robotic control technologies emphasize the integration of force-controlled robots with advanced sensors and AI algorithms to enhance adaptability and precision in unstructured environments. Position-controlled robots are evolving with hybrid control systems that combine position accuracy and force feedback for improved safety and interaction in collaborative tasks. The convergence of machine learning and real-time force sensing is driving the development of smarter, more responsive robotic systems capable of dynamic decision-making and autonomous adjustments.

Force-controlled Robot vs Position-controlled Robot Infographic

libmatt.com

libmatt.com