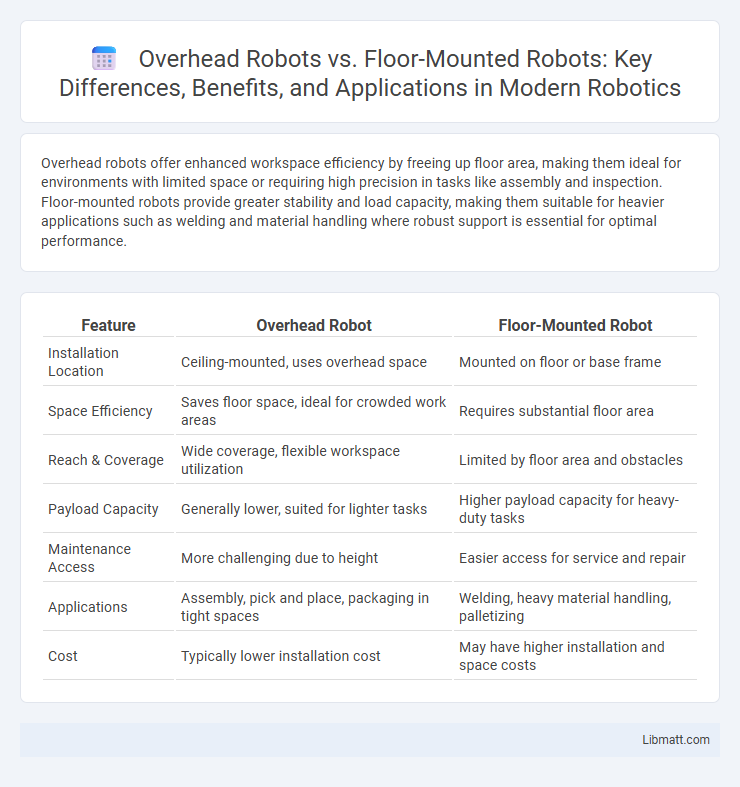

Overhead robots offer enhanced workspace efficiency by freeing up floor area, making them ideal for environments with limited space or requiring high precision in tasks like assembly and inspection. Floor-mounted robots provide greater stability and load capacity, making them suitable for heavier applications such as welding and material handling where robust support is essential for optimal performance.

Table of Comparison

| Feature | Overhead Robot | Floor-Mounted Robot |

|---|---|---|

| Installation Location | Ceiling-mounted, uses overhead space | Mounted on floor or base frame |

| Space Efficiency | Saves floor space, ideal for crowded work areas | Requires substantial floor area |

| Reach & Coverage | Wide coverage, flexible workspace utilization | Limited by floor area and obstacles |

| Payload Capacity | Generally lower, suited for lighter tasks | Higher payload capacity for heavy-duty tasks |

| Maintenance Access | More challenging due to height | Easier access for service and repair |

| Applications | Assembly, pick and place, packaging in tight spaces | Welding, heavy material handling, palletizing |

| Cost | Typically lower installation cost | May have higher installation and space costs |

Introduction to Overhead and Floor-Mounted Robots

Overhead robots are designed to operate suspended from the ceiling or an overhead structure, maximizing floor space and enabling unobstructed movement in manufacturing environments. Floor-mounted robots are installed directly on the ground, providing stable and robust support for heavy-duty operations with high precision. Choosing between overhead and floor-mounted robots depends on your workspace layout, load requirements, and application needs to optimize production efficiency.

Key Differences Between Overhead and Floor-Mounted Robots

Overhead robots are installed above the workspace, providing a wider range of motion and freeing up valuable floor space, while floor-mounted robots are anchored to the ground, offering greater stability and higher payload capacity. Overhead robots excel in applications requiring flexible reach and compact layouts, whereas floor-mounted robots are better suited for heavy-duty tasks and environments needing robust support. Choosing the right robot depends on your specific workspace constraints, load requirements, and operational needs.

Space Utilization: Maximizing Factory Layout

Overhead robots optimize space utilization by operating above the work area, freeing up valuable floor space for other equipment and personnel movement. Floor-mounted robots require designated ground clearance, potentially limiting factory layout flexibility and reducing usable workspace. Prioritizing overhead robots enhances factory efficiency by maximizing available floor space and enabling more streamlined material flow.

Installation Requirements and Flexibility

Overhead robots require ceiling-mounted infrastructure, which demands robust support structures and precise alignment for installation, limiting placement flexibility but maximizing floor space. Floor-mounted robots offer more adaptable installation options with simpler anchoring to existing floors, allowing easier repositioning and layout changes in dynamic production environments. Your choice depends on available space constraints and the need for operational flexibility within the manufacturing setup.

Payload Capacity and Reach Comparison

Overhead robots typically offer higher payload capacities, ranging from 10 to 500 kilograms, making them suitable for heavy-duty tasks, while floor-mounted robots generally support payloads between 5 and 300 kilograms. Overhead robots provide superior reach, often extending up to 4 meters or more, ideal for large workspace coverage, whereas floor-mounted robots usually have a reach limited to about 2 to 3 meters. The combination of higher payload capacity and extended reach makes overhead robots preferable in applications requiring handling of bulky or heavy items across expansive areas.

Maintenance and Accessibility Considerations

Overhead robots offer easier maintenance and enhanced accessibility by freeing floor space, enabling technicians to reach components without obstruction. Floor-mounted robots may require more downtime and careful planning for repairs due to their fixed position and proximity to other equipment. Your choice between the two should weigh ease of maintenance and accessibility to ensure minimal disruption to production workflows.

Application Suitability by Industry

Overhead robots excel in electronics and automotive assembly lines where space optimization and precise, multi-axis movement are critical for handling small components or performing intricate tasks. Floor-mounted robots are better suited for heavy-duty applications in industries such as metal fabrication, packaging, and large-scale material handling where stability and load capacity are paramount. Manufacturing plants prioritize overhead robots for high-density environments, while floor-mounted robots are preferred in sectors demanding robust, versatile automation solutions.

Safety and Worker Interaction

Overhead robots enhance safety by operating above the workspace, reducing human-robot collision risks and enabling unobstructed floor access for workers. Floor-mounted robots require carefully designed safety zones and barriers to prevent accidental contact with personnel during operation. Effective integration of sensors and collaborative robot technologies improves worker interaction in both setups, but overhead robots inherently minimize interference in shared environments.

Cost Implications and ROI Analysis

Overhead robots typically have higher initial installation costs due to complex mounting requirements but offer space-saving advantages that can enhance factory floor efficiency and increase ROI over time. Floor-mounted robots generally involve lower upfront expenses and simpler setup but may consume valuable workspace, potentially limiting production capacity and prolonging ROI realization. Your choice should weigh these cost implications against operational needs to optimize long-term profitability.

Choosing the Right Robot Configuration

Choosing the right robot configuration depends on your workspace layout and specific application needs. Overhead robots excel in saving floor space and providing superior reach in compact environments, while floor-mounted robots offer greater stability and load capacity for heavy-duty tasks. Evaluating your operational priorities ensures you select the most efficient and cost-effective robotic solution.

Overhead Robot vs Floor-Mounted Robot Infographic

libmatt.com

libmatt.com