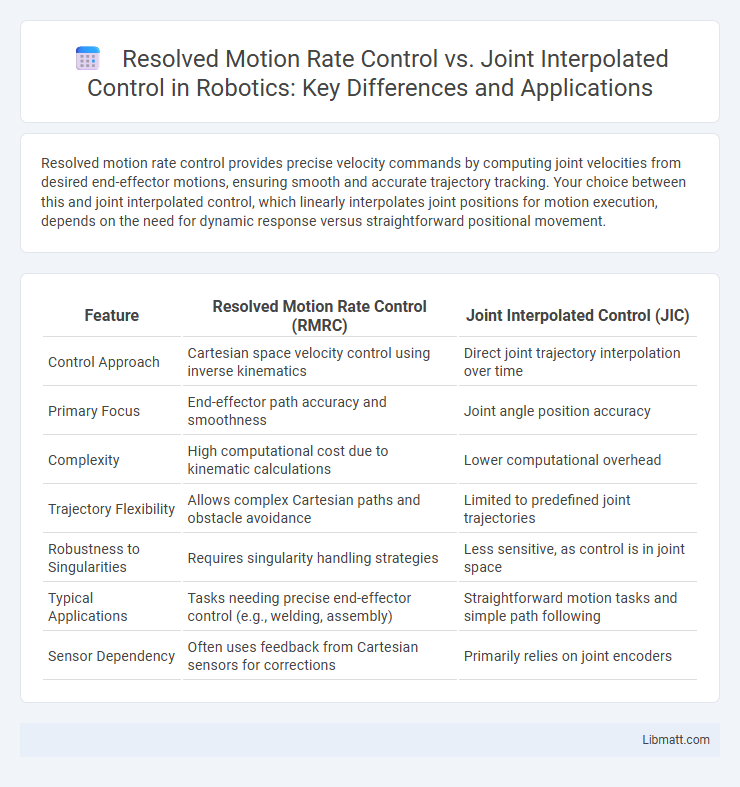

Resolved motion rate control provides precise velocity commands by computing joint velocities from desired end-effector motions, ensuring smooth and accurate trajectory tracking. Your choice between this and joint interpolated control, which linearly interpolates joint positions for motion execution, depends on the need for dynamic response versus straightforward positional movement.

Table of Comparison

| Feature | Resolved Motion Rate Control (RMRC) | Joint Interpolated Control (JIC) |

|---|---|---|

| Control Approach | Cartesian space velocity control using inverse kinematics | Direct joint trajectory interpolation over time |

| Primary Focus | End-effector path accuracy and smoothness | Joint angle position accuracy |

| Complexity | High computational cost due to kinematic calculations | Lower computational overhead |

| Trajectory Flexibility | Allows complex Cartesian paths and obstacle avoidance | Limited to predefined joint trajectories |

| Robustness to Singularities | Requires singularity handling strategies | Less sensitive, as control is in joint space |

| Typical Applications | Tasks needing precise end-effector control (e.g., welding, assembly) | Straightforward motion tasks and simple path following |

| Sensor Dependency | Often uses feedback from Cartesian sensors for corrections | Primarily relies on joint encoders |

Introduction to Robotic Motion Control Methods

Resolved motion rate control and joint interpolated control represent distinct methods in robotic motion control, impacting precision and efficiency. Resolved motion rate control calculates end-effector velocities for smooth trajectory tracking, enhancing real-time responsiveness in complex tasks. Joint interpolated control focuses on individual joint movements for coordinated positioning, offering straightforward implementation suitable for simpler robotic operations involving your system.

Overview of Resolved Motion Rate Control

Resolved Motion Rate Control (RMRC) is a robotic control method that calculates the joint velocities required to achieve a desired end-effector velocity in Cartesian space. It uses the robot's Jacobian matrix to map Cartesian velocities into joint velocities, enabling smooth and continuous movement along a specified trajectory. Your robotic system benefits from RMRC by enhancing precision in tasks requiring dynamic adjustments and real-time velocity commands.

Fundamentals of Joint Interpolated Control

Joint Interpolated Control operates by independently controlling each joint's motion to achieve a coordinated path, emphasizing precise angular positioning over time. This method calculates the trajectory for each joint in joint space, ensuring smooth and synchronized movements by interpolating joint angles rather than Cartesian coordinates. Its fundamental advantage lies in simplifying inverse kinematics computations, making it efficient for manipulators with complex configurations but potentially less optimal for tasks requiring smooth end-effector trajectories.

Key Differences Between Resolved and Joint Interpolated Control

Resolved motion rate control calculates end-effector velocities and translates them into joint velocities, enabling smoother, task-oriented movements ideal for precise path tracking. Joint interpolated control directly commands each joint to move between positions along predefined trajectories, focusing on individual joint motion without explicit consideration of end-effector motion. Your choice depends on whether coordinated task-space accuracy or simpler joint-space execution is more critical for your robotic application.

Advantages of Resolved Motion Rate Control

Resolved Motion Rate Control offers precise and smooth trajectory tracking by directly computing joint velocities from desired end-effector motions, enhancing control accuracy in complex tasks. It effectively handles kinematic constraints and singularities, providing more stable and flexible robotic manipulations compared to Joint Interpolated Control. Your robotic system benefits from improved responsiveness and adaptability in dynamic environments, making it ideal for advanced automation applications.

Benefits of Joint Interpolated Control

Joint Interpolated Control offers enhanced precision by synchronizing multiple joint movements, resulting in smoother and more accurate trajectories compared to Resolved Motion Rate Control. This method reduces computational complexity while improving real-time control performance in robotic systems. Your robotic applications benefit from increased stability and coordinated motion, essential for tasks requiring high accuracy and fluid motion.

Limitations of Each Control Strategy

Resolved motion rate control struggles with singularities and may produce unpredictable behavior near these points, limiting precise control in complex robotic tasks. Joint interpolated control can lead to inefficient or suboptimal paths since it moves each joint independently without considering the overall end-effector trajectory. Your choice between these strategies should consider the trade-off between smooth Cartesian motion and straightforward joint-level command execution.

Application Scenarios for Both Methods

Resolved motion rate control excels in robotic systems requiring real-time adjustment to dynamic environments, such as autonomous mobile robots navigating unpredictable terrains or robotic arms executing tasks involving continuous sensory feedback. Joint interpolated control is more suited for precision-oriented applications like CNC machining or robotic assembly lines, where smooth, predefined joint trajectories ensure consistent and repeatable motion. Both control methods are essential in advanced robotics, balancing flexibility in adaptive tasks and accuracy in structured operations.

Performance Comparison: Accuracy and Efficiency

Resolved motion rate control offers higher accuracy by directly computing velocity commands based on the robot's kinematics, minimizing cumulative errors during motion. Joint interpolated control improves efficiency by generating smooth joint trajectories that reduce abrupt movements, enhancing stability and operational speed. Your choice should consider whether precision (resolved motion rate control) or smooth, efficient joint execution (joint interpolated control) aligns better with the application requirements.

Choosing the Right Control Method for Robotics

Choosing the right control method for robotics depends on the application's precision and complexity. Resolved motion rate control excels in tasks requiring smooth continuous trajectories by directly controlling end-effector velocity, while joint interpolated control is better suited for coordinated joint movements with simpler path requirements. Your selection between these methods impacts robot responsiveness and accuracy, ultimately influencing performance in industrial automation or complex manipulation tasks.

Resolved motion rate control vs Joint interpolated control Infographic

libmatt.com

libmatt.com