Overhead rail robots maximize factory floor space by operating above the work area, providing seamless, unobstructed movement ideal for high-density environments. Your choice between overhead rail and floor-track robots should consider factors like installation complexity, maintenance access, and load capacity to best align with your operational workflow.

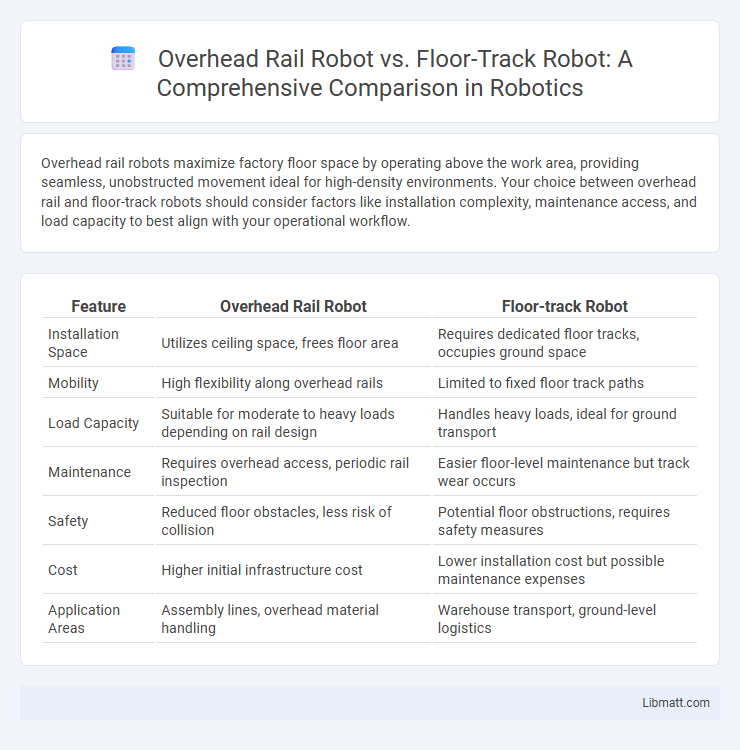

Table of Comparison

| Feature | Overhead Rail Robot | Floor-track Robot |

|---|---|---|

| Installation Space | Utilizes ceiling space, frees floor area | Requires dedicated floor tracks, occupies ground space |

| Mobility | High flexibility along overhead rails | Limited to fixed floor track paths |

| Load Capacity | Suitable for moderate to heavy loads depending on rail design | Handles heavy loads, ideal for ground transport |

| Maintenance | Requires overhead access, periodic rail inspection | Easier floor-level maintenance but track wear occurs |

| Safety | Reduced floor obstacles, less risk of collision | Potential floor obstructions, requires safety measures |

| Cost | Higher initial infrastructure cost | Lower installation cost but possible maintenance expenses |

| Application Areas | Assembly lines, overhead material handling | Warehouse transport, ground-level logistics |

Introduction to Overhead Rail Robots and Floor-track Robots

Overhead rail robots operate on elevated tracks mounted above the workspace, providing enhanced floor space utilization and allowing seamless movement over obstacles. Floor-track robots navigate along fixed ground paths, ideal for stable, high-precision material handling in controlled environments like warehouses and manufacturing lines. Both systems optimize automation efficiency but differ in spatial integration and application suitability.

Design and Structural Differences

Overhead rail robots feature a suspended design, utilizing ceiling-mounted rails that save valuable floor space and enable multi-axis movement above workstations. Floor-track robots operate on ground-level tracks, requiring stable, reinforced floors to handle their weight and enabling easy access for maintenance and load handling. The structural difference lies in the overhead system's minimal footprint versus the floor-track robot's robust, ground-based framework supporting heavier payloads.

Installation Requirements and Space Utilization

Overhead rail robots require ceiling-mounted tracks, minimizing floor space usage and enabling operation in environments with limited ground clearance, making them ideal for facilities with congested floors. Floor-track robots need designated floor rails or tracks, occupying valuable floor area and potentially restricting workspace flexibility and movement paths. Installing overhead systems often demands structural reinforcement and precise alignment, while floor-track installations involve embedding tracks at ground level, which can impact workflow and cleaning processes.

Movement and Navigation Capabilities

Overhead rail robots move along fixed tracks mounted above the workspace, enabling vertical and horizontal navigation with precision and minimal floor obstruction, ideal for environments requiring clean and safe floor space. Floor-track robots navigate via guided rails installed on the ground, offering robust, stable movement and easier access for maintenance but requiring clear floor pathways. Your choice depends on whether vertical clearance and floor space optimization or straightforward ground-based navigation better suits your operational needs.

Load Handling and Payload Capacity

Overhead rail robots excel in load handling by utilizing ceiling-mounted tracks that free up floor space, allowing them to manage heavier payloads often exceeding 500 kg with high precision. Floor-track robots typically have lower payload capacities, usually up to 200 kg, due to limitations posed by floor friction and space constraints. Overhead systems ensure efficient transport of bulky or heavy items in manufacturing and warehousing environments where maximizing payload capacity is critical.

Safety Considerations and Workplace Integration

Overhead rail robots reduce floor-level hazards by operating above human workspaces, minimizing collision risks and enhancing overall safety in crowded environments. Floor-track robots require clear pathways and robust obstacle detection systems to prevent accidents, making their integration dependent on well-defined traffic management. Choosing the right system impacts Your workplace layout and safety protocols, with overhead rail robots often offering superior integration in complex, space-constrained settings.

Maintenance and Longevity Comparison

Overhead rail robots require less frequent maintenance due to their elevated position, which minimizes exposure to dust, debris, and floor-level damage, enhancing their operational longevity. Floor-track robots experience more wear and tear from direct contact with floor surfaces, increasing maintenance needs and potentially shortening their service life. Choosing an overhead rail robot can optimize your maintenance schedule and extend the lifespan of your automation system.

Energy Efficiency and Operating Costs

Overhead rail robots typically consume less energy due to reduced friction and smoother, elevated pathways, resulting in lower operating costs and maintenance requirements over time. Floor-track robots encounter more resistance from surface irregularities and debris, leading to higher energy consumption and increased wear on components, which elevates overall expenses. Implementing overhead rail systems can offer significant long-term energy savings and cost efficiency in automated material handling.

Application Suitability and Industry Use Cases

Overhead rail robots excel in applications requiring space efficiency and flexibility, making them ideal for industries like automotive manufacturing, warehousing, and electronics assembly where ceiling-mounted systems improve workflow without occupying floor space. Floor-track robots are better suited for heavy payload transport and repetitive tasks in industries such as logistics, food production, and heavy machinery assembly, where robust ground-level movement ensures stability and precision. Understanding Your specific operational needs and spatial constraints will guide the choice between these robotic systems, optimizing productivity and integration within your industry.

Choosing the Right Robot for Your Facility

Overhead rail robots maximize floor space by operating above production lines, making them ideal for facilities with limited workspace and high automation demands. Floor-track robots offer greater payload capacity and stability for heavier materials, suitable for manufacturing environments requiring precise handling on the ground. Evaluating your facility's layout, load requirements, and workflow integration will help you choose the right robot to optimize efficiency and productivity.

Overhead Rail Robot vs Floor-track Robot Infographic

libmatt.com

libmatt.com