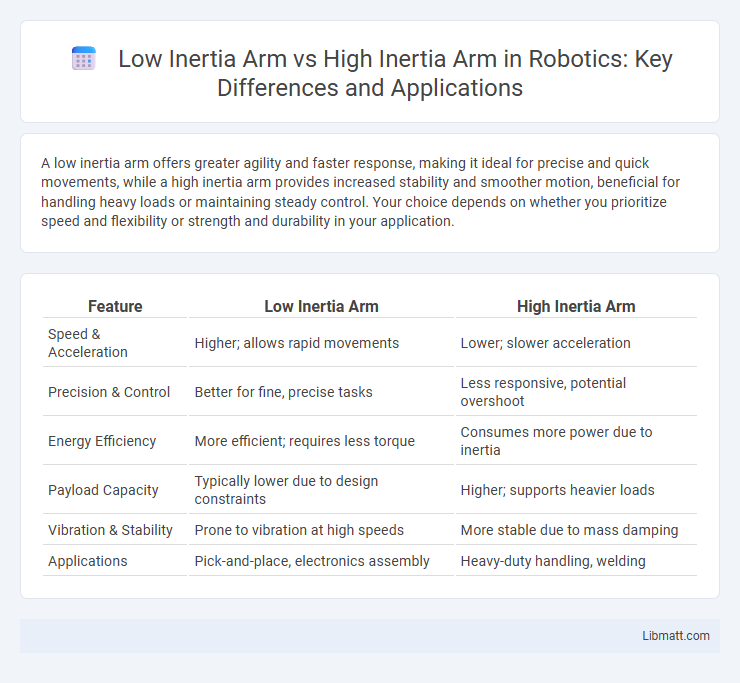

A low inertia arm offers greater agility and faster response, making it ideal for precise and quick movements, while a high inertia arm provides increased stability and smoother motion, beneficial for handling heavy loads or maintaining steady control. Your choice depends on whether you prioritize speed and flexibility or strength and durability in your application.

Table of Comparison

| Feature | Low Inertia Arm | High Inertia Arm |

|---|---|---|

| Speed & Acceleration | Higher; allows rapid movements | Lower; slower acceleration |

| Precision & Control | Better for fine, precise tasks | Less responsive, potential overshoot |

| Energy Efficiency | More efficient; requires less torque | Consumes more power due to inertia |

| Payload Capacity | Typically lower due to design constraints | Higher; supports heavier loads |

| Vibration & Stability | Prone to vibration at high speeds | More stable due to mass damping |

| Applications | Pick-and-place, electronics assembly | Heavy-duty handling, welding |

Understanding Inertia in Robotic Arms

Inertia in robotic arms determines how quickly the arm can change its motion, with low inertia arms enabling faster, more precise movements and high inertia arms offering greater stability and strength under heavier loads. Low inertia designs reduce resistance to acceleration and deceleration, making them ideal for applications requiring agility and rapid response. Your choice between low and high inertia arms impacts the robot's efficiency in tasks involving speed, precision, and load-bearing capacity.

Low Inertia Arm: Definition and Key Characteristics

Low inertia arms feature a reduced mass and compact design, enabling faster acceleration and more precise movements in robotic applications. These arms are optimized for responsiveness and energy efficiency, making them ideal for tasks requiring rapid, accurate positioning. Key characteristics include lightweight construction, minimal resistance to motion changes, and enhanced control dynamics.

High Inertia Arm: Definition and Key Characteristics

High inertia arms are designed with increased mass distribution further from the pivot point, enhancing stability and resistance to external disturbances during motion. This increased inertia improves precision in tasks requiring steady, controlled movements, especially in robotic and mechanical applications. Key characteristics include greater torque requirements for acceleration and deceleration, along with enhanced damping of vibrations and oscillations.

Performance Differences: Speed and Responsiveness

Low inertia arms offer enhanced speed and responsiveness, making them ideal for tasks requiring quick, precise movements and agile control. High inertia arms, while slower to accelerate and decelerate, provide greater stability and smoother motion, which benefits applications involving heavy loads or steady, forceful operations. Understanding your specific performance needs helps in choosing the right arm type for optimal efficiency.

Energy Efficiency Considerations

Low inertia arms require less energy to accelerate and decelerate, resulting in higher energy efficiency during repetitive tasks and fast movements. High inertia arms consume more power due to greater resistance to changes in motion, increasing overall energy expenditure. Selecting a low inertia arm can significantly reduce operational energy costs while maintaining performance in dynamic robotic applications.

Control and Stability Challenges

Low inertia arms offer quicker response times and enhanced maneuverability, making them ideal for tasks requiring precision and rapid adjustments, but they can suffer from reduced stability due to less resistance against external forces. High inertia arms provide greater control and stability in operations involving heavy loads or sustained force, as their mass dampens vibrations and external disturbances, though this comes at the cost of slower response and agility. Balancing control and stability challenges depends on the specific application requirements, with low inertia designs favoring dynamic control and high inertia designs ensuring steadiness under load.

Application Suitability: Low vs High Inertia Arms

Low inertia arms excel in applications requiring rapid, precise movements such as robotics for assembly lines and medical devices, where quick response times are critical. High inertia arms are more suitable for heavy-duty tasks like material handling, welding, or machining, where stability and smooth force application outweigh speed. Choosing between low and high inertia arms hinges on the balance between speed requirements and load capacity in specific industrial or manufacturing environments.

Cost Implications and Maintenance

Low inertia arms typically have lower manufacturing costs due to simpler design and lighter materials, reducing initial investment and operational energy consumption. High inertia arms, while offering greater stability and precision for heavy-duty tasks, often incur higher maintenance expenses because of increased wear on components and the need for robust support structures. Choosing between low and high inertia arms depends on balancing upfront costs and long-term maintenance demands relative to the specific application requirements.

Safety and Risk Factors

Low inertia arms offer greater responsiveness and precision, reducing the likelihood of accidental collisions and enhancing operator safety in dynamic environments. High inertia arms, while more stable during heavy-duty tasks, pose increased risks due to slower reaction times and greater momentum, which can exacerbate injury chances during unexpected impacts. Effective safety protocols and advanced sensor integration are essential to mitigate risks associated with high inertia robotic arms.

Choosing the Right Inertia Arm for Your Needs

Selecting the appropriate inertia arm depends on the specific requirements of your training or rehabilitation routine. Low inertia arms offer quicker, more responsive movement suitable for activities emphasizing speed and agility, while high inertia arms provide greater resistance, ideal for strength building and muscle endurance. Evaluating factors such as your current fitness level, training goals, and the type of exercise will guide you in choosing the optimal inertia arm that enhances performance and reduces injury risk.

Low inertia arm vs High inertia arm Infographic

libmatt.com

libmatt.com